Wall climbing robot airflow adsorption technology and walk operation platform

A wall-climbing robot and operating platform technology, applied in motor vehicles, transportation and packaging, etc., can solve the problems of limited adsorption force, small adsorption surface gap, poor energy efficiency, etc., and achieve the effect of simple structure and high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

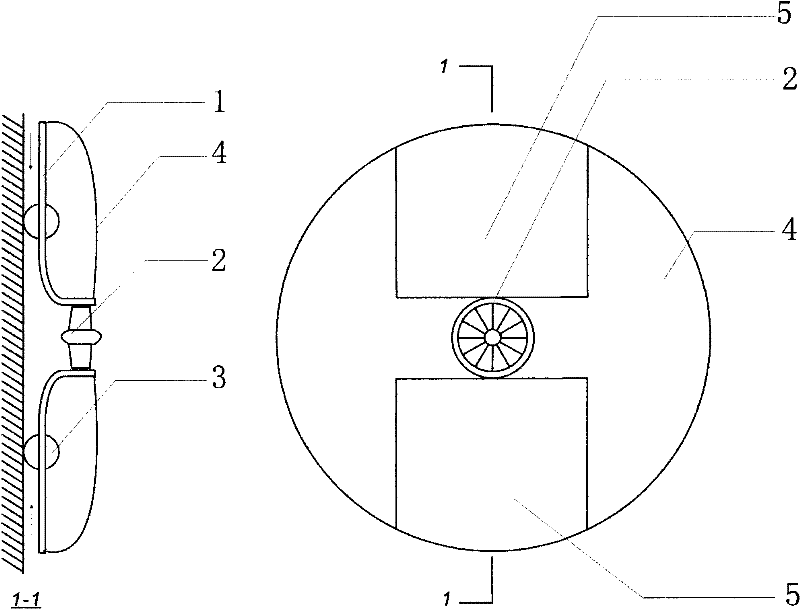

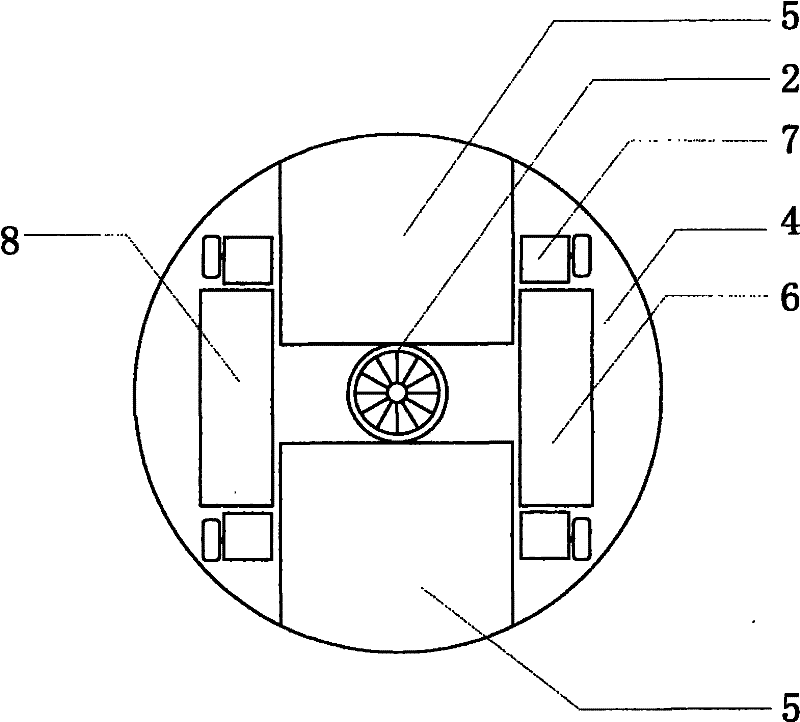

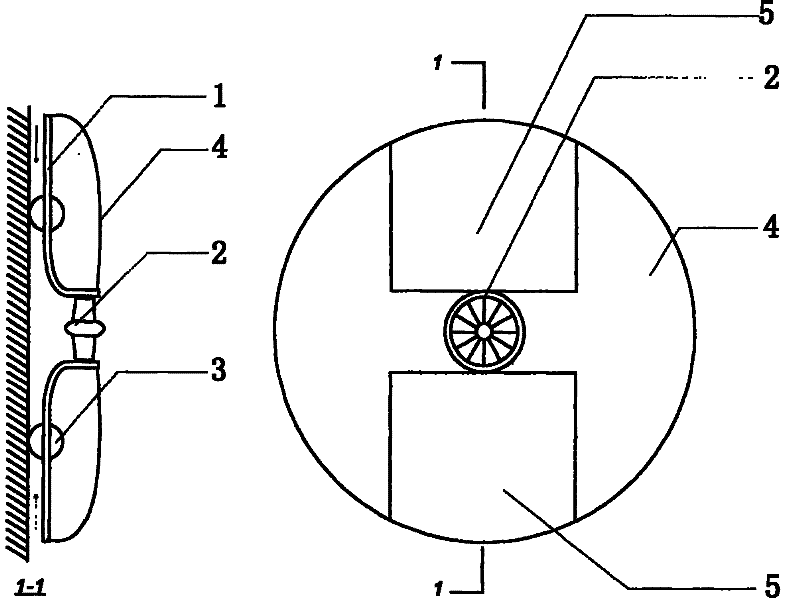

[0017] The specific implementation method of the present invention to realize adsorption and walking is described in detail in conjunction with the accompanying drawings as follows:

[0018] The implementation of the adsorption function: the high-speed airflow generated by the fan power group 2 is used to generate a high-speed airflow between the adsorption disk 1 and the wall surface, and the negative pressure is generated by the relative flow velocity difference between the two sides of the adsorption disk 1. Adsorption is completed when the gravity and load of the wall robot platform are balanced with friction.

[0019] Implementation of walking control: the walking wheels 3 are driven by the servo motors of the left and right groups of walking power modules 5, and the walking control module 6 receives the operator's instructions through wired or wireless means and controls the synchronization or reverse of the servo motors of the left and right groups of walking power modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com