Far infrared insect-proof and waterproof refreshing fruit packaging material produced by utilizing yellow soil and manufacturing method thereof

A packaging material, far-infrared technology, applied in chemical instruments and methods, paper coatings, plant protection covers, etc., can solve the problems of reduced economic value, poor fruit flesh, unbalanced temperature and humidity, etc., to promote fruit growth, prevent The effect of water volatilization and solving the problem of water vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

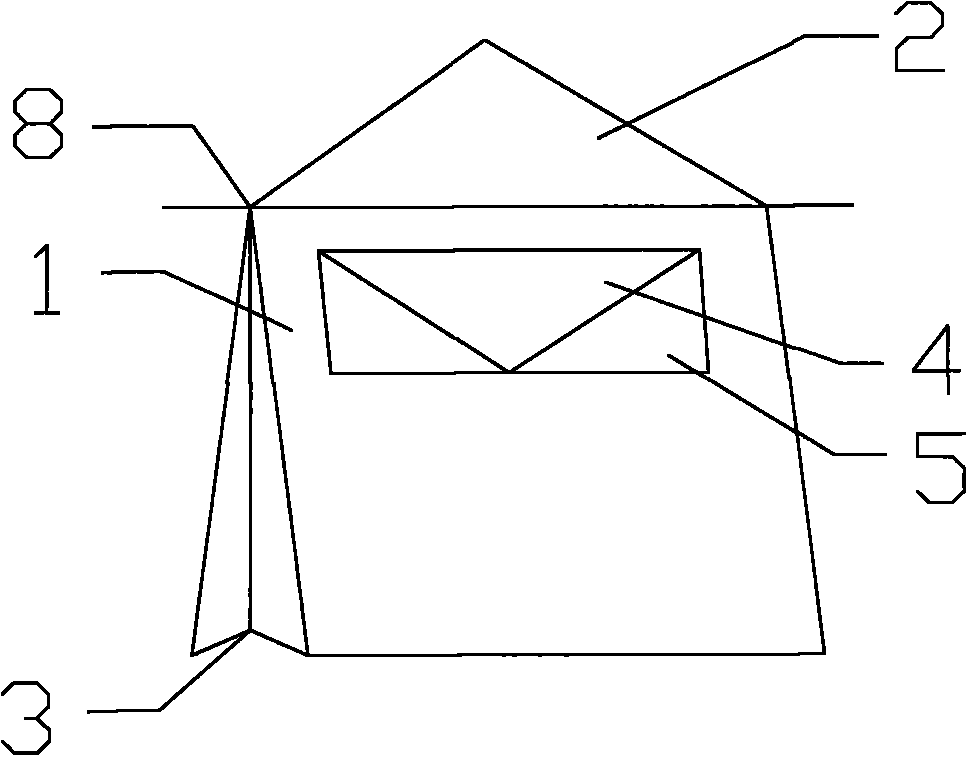

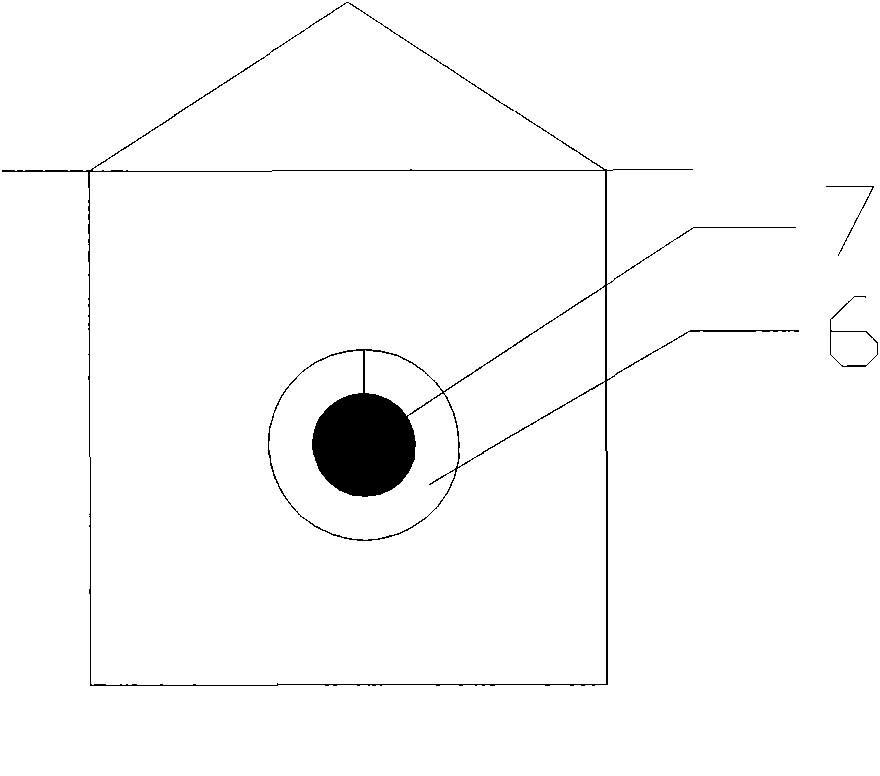

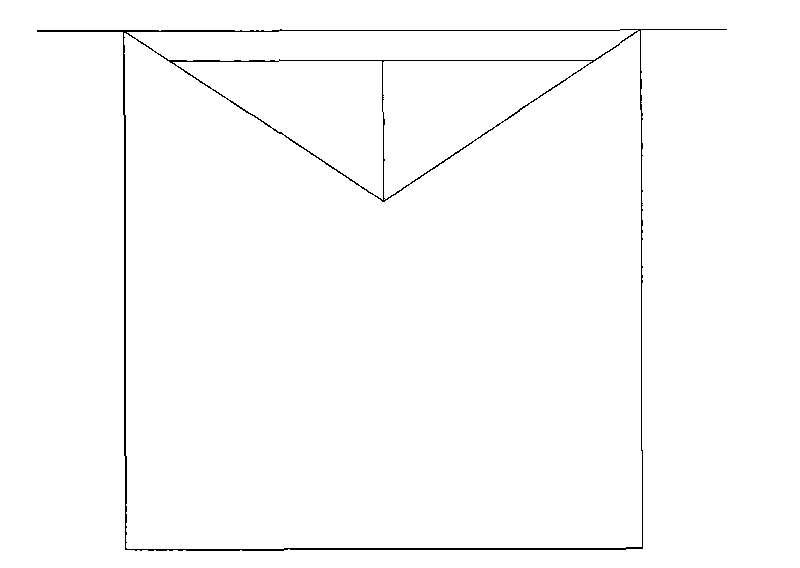

[0021] Take good-quality natural red loess, use a crushing device to grind it into a size of 1200 mesh, weigh 10g of this kind of loess, 20g of edible cornstarch, 10g of illite and 60g of water, mix the above materials, stir evenly, and put the mixture in Heat and boil at 100°C for 20 minutes to obtain a loess mixture. Mix 0.1g of wax, 10g of edible cornstarch and 89.9g of water. After stirring evenly, heat and boil at 100°C for 20 minutes to form a waterproof glue. Feed 100g base paper into the coating machine and put it on the frame fixed with bearings on both sides. The diameter of the upper wheel of the coating machine is 250mm and the diameter of the lower wheel is 200mm. The lower wheel of the coating machine is used on the lower side of the base paper Evenly coat 10g of loess mixture per square meter, apply the upper wheel of the coating machine to evenly coat the waterproof glue on the lower side of the base paper, and then press the upper wheel to make the waterproof ...

Embodiment 2

[0024] Take good-quality natural red loess, use a crushing device to grind it into a size of 1500 mesh, weigh 29g of this kind of loess, 10g of edible cornstarch, 10g of illite and 51g of water, mix the above materials, stir evenly, and put the mixture in Heat and boil at 120° C. for 10 minutes to obtain a loess mixture. Mix 0.3g of wax, 40g of edible cornstarch and 59.7g of water, stir evenly, heat and boil at 120°C for 10 minutes to form a waterproof glue. Feed 100g base paper into the coating machine and put it on the frame fixed with bearings on both sides. The diameter of the upper wheel of the coating machine is 250mm and the diameter of the lower wheel is 200mm. The lower wheel of the coating machine is used on the lower side of the base paper Evenly coat 20g of loess mixture per square meter, apply the upper wheel of the coating machine to evenly coat the waterproof glue on the upper side of the paper, and then press the upper wheel to make the waterproof glue adhere t...

Embodiment 3

[0026]Take good quality natural red loess, grind it into 1300 mesh size with a crushing device, weigh 10g of this kind of loess, 39g of edible cornstarch, 1g of illite and 50g of water, mix the above materials, stir evenly, and put the mixture in Heat and boil at 110° C. for 15 minutes to obtain a loess mixture. Mix 0.2g of wax, 30g of edible cornstarch and 69.8g of water, stir evenly, heat and boil at 110°C for 15 minutes to form a waterproof glue. Feed 80g base paper into the coating machine and put it on the frame fixed with bearings on both sides. The diameter of the upper wheel of the coating machine is 250mm, and the diameter of the lower wheel is 200mm. The lower wheel of the coating machine is used on the lower side of the base paper Evenly coat 15g of loess mixture per square meter, apply the upper wheel of the coating machine to evenly coat the waterproof glue on the upper side of the base paper, and then press the upper wheel to make the waterproof glue adhere to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com