Wafer heating apparatus, electrostatic chuck, and method for manufacturing wafer heating apparatus

A heating device and wafer technology, which is applied in the manufacture of semiconductor/solid-state devices, circuits, electrical components, etc., can solve the problems of not being able to achieve heat uniformity, the amount of filler added is limited, and improved, and achieves uniform heat distribution and reduction of heat. Small deviation, uniform heat diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] Embodiments of the wafer heating apparatus of the present invention will be described below.

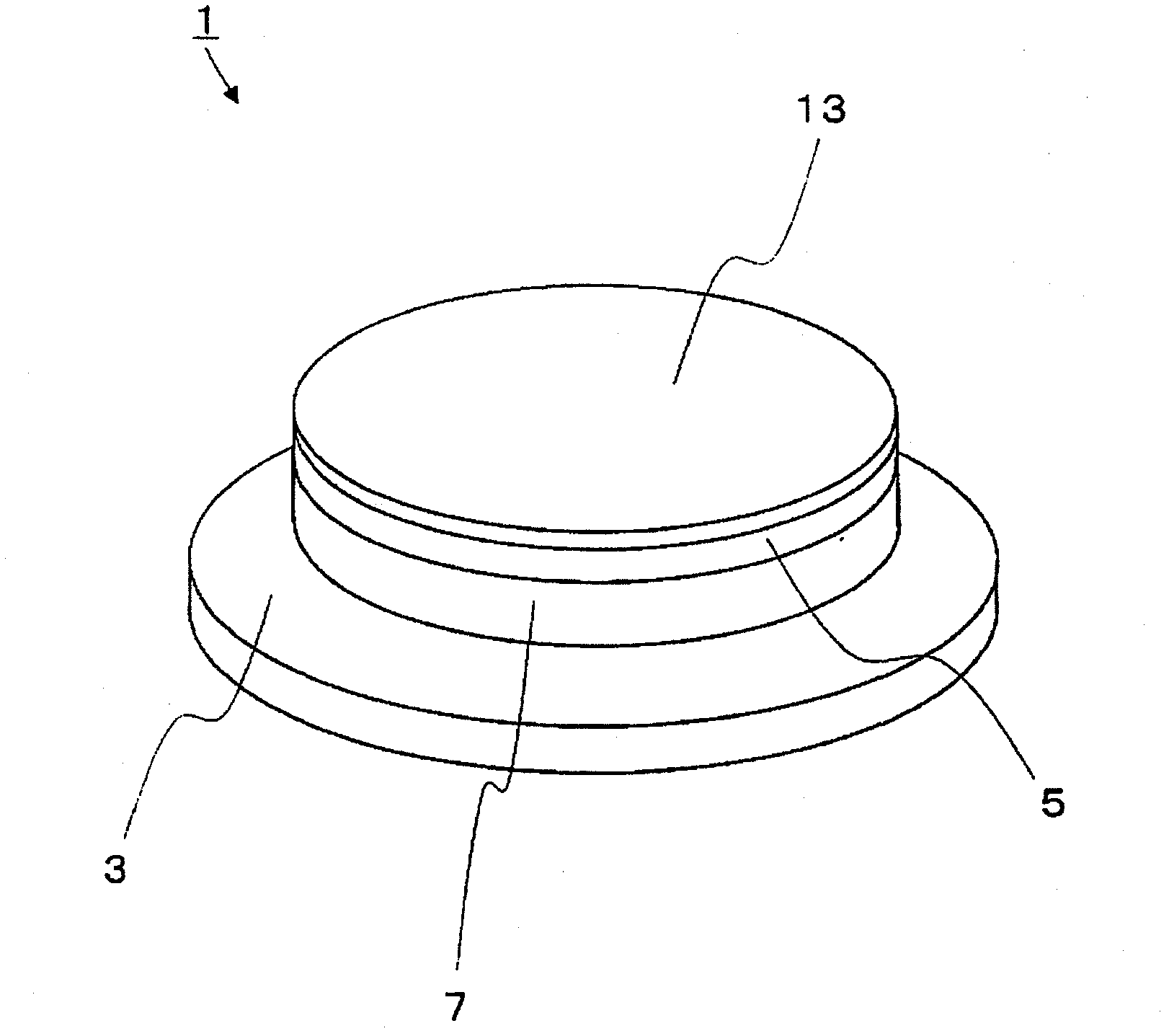

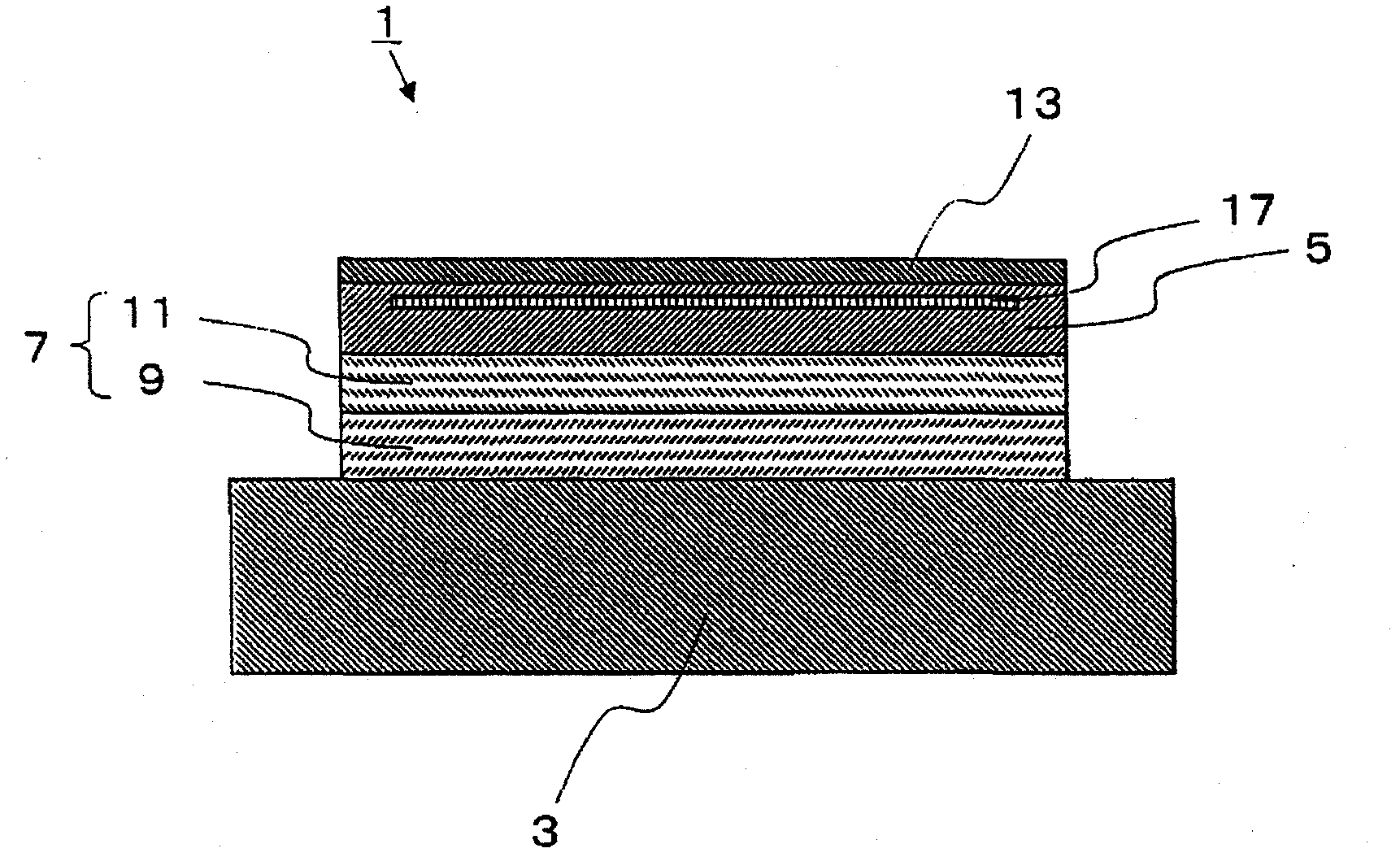

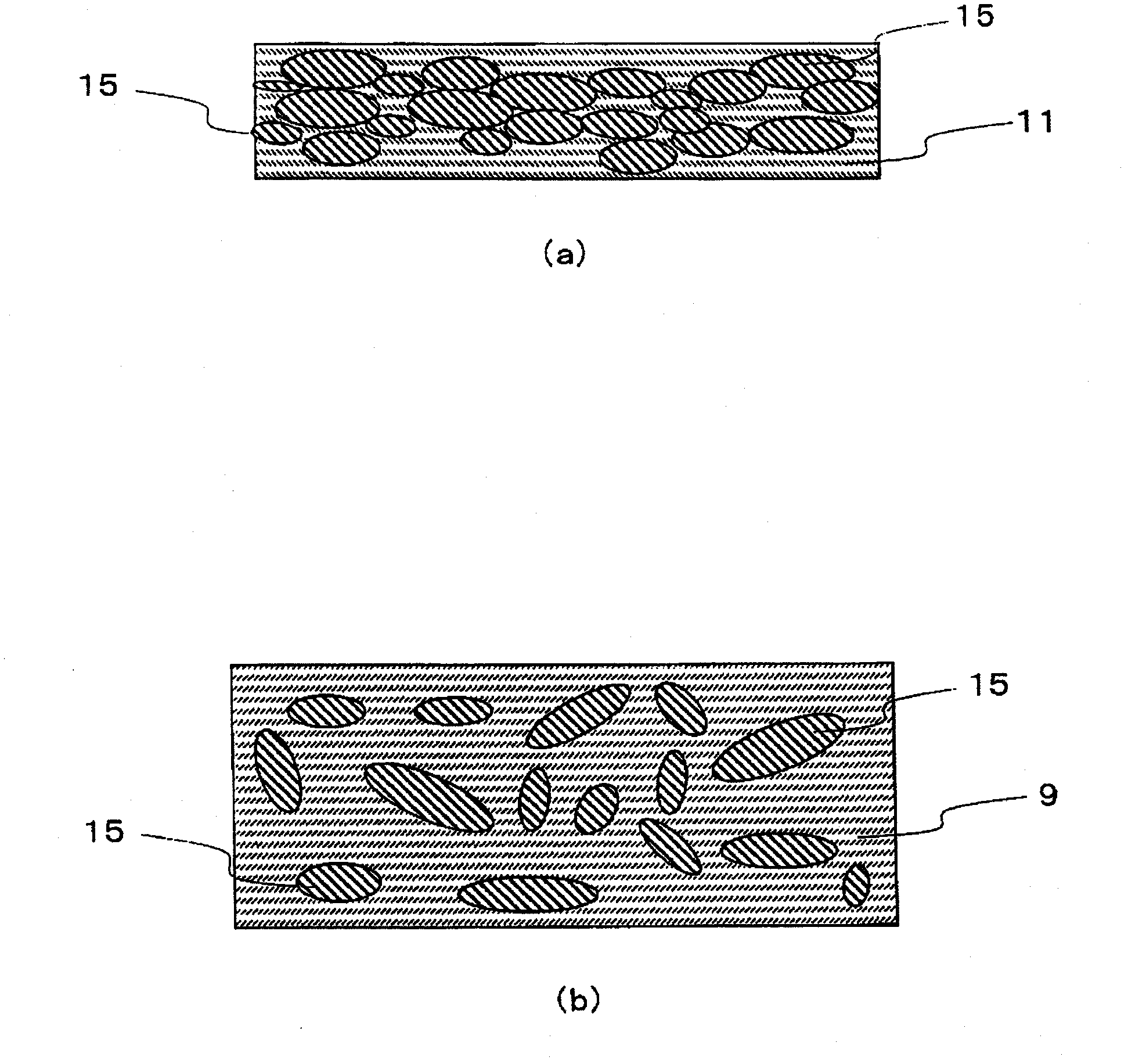

[0071] Made as follows figure 1 , figure 2 A wafer heating device 1 of the structure shown.

[0072] First, as the base member 3, a circle made of an aluminum alloy composed of an Al-Mg-Si alloy (aluminum alloy standard number 6061 (JIS H 4000, etc.)) and in which a cooling passage through which a cooling medium such as water can flow is formed. Plate-shaped base member. The size of the base member 3 is 300 mm in diameter and 35 mm in thickness. In addition, the base member 3 is provided with a terminal hole for supplying electricity to the heating electrode 17 after bonding the insulating layer 5 in which the heating electrode 17 is embedded.

[0073] Next, the heating electrode 17 is made of inconel (trade name (Ni-Cr-Fe alloy)), and is formed into a predetermined pattern by etching or the like. The disc-shaped insulating layer 5 in which the heater electrode 17 is bur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com