Hybrid preparation method of high-performance sintered NdFeB permanent magnet

A neodymium-iron-boron, permanent magnet technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of low performance indicators of magnets, difficult to overcome α-Fe, segregation of main phase components, etc. The effect of remanence and magnetic energy product to avoid segregation of main phase components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

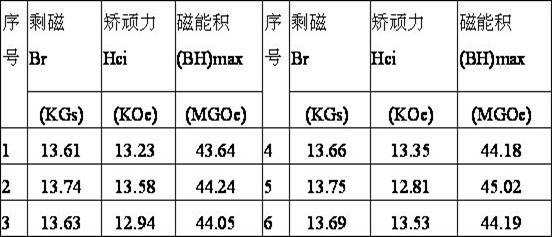

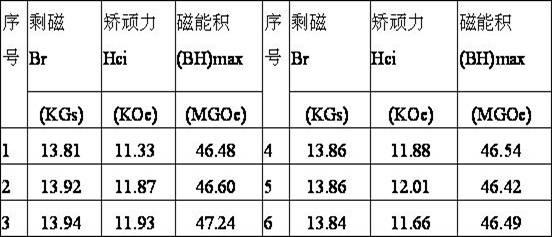

Embodiment 1

[0017] To prepare a formula of Nd 30 B 0.95Al 0.4 Fe 68.65 (all the following ratios are weight percentages), first use the existing strip stripping process, smelt and strip the raw materials according to the above proportions, the main phase and The neodymium-rich phase is formed at the same time, and then the main phase and the neodymium-rich phase alloy are subjected to hydrogen crushing, jet milling, magnetic field orientation, pressing, sintering, and tempering.

[0018] Then adopt the method described in the present invention to make a magnet: the main phase and the neodymium-rich phase are designed separately, the raw material ratio of the main phase is Nd29.5 B 0.95Fe 69.55, and after smelting, it is cooled by stripping technology, hydrogen crushing, and air-flow milling The ratio of Nd54.5 B0.95Al 20 Fe 24.55 is Nd54.5 B0.95Al 20 Fe 24.55. After smelting, the ingot casting process is used for cooling, hydrogen crushing, and jet milling. After that, the main phase and N...

Embodiment 2

[0026] A formula is prepared as Nd 30 Dy 0.8 B 1.0 Co 0.5 Cu 0.25 Fe 67.45. First, the existing stripping process is adopted, and the raw materials are smelted and stripped according to the above ratio. The main phase is formed at the same time as the rich neodymium, and then The main phase and neodymium-rich phase alloy are subjected to hydrogen crushing, jet milling, magnetic field orientation, pressing, sintering and tempering.

[0027] Then adopt the method described in the present invention to obtain a magnet: the main phase and the Nd-rich phase are designed separately, the raw material ratio of the main phase is Nd30 B 1.0 Fe 69, and after smelting, the belt-slinging process is used for cooling, hydrogen crushing, and air-flow milling; The neodymium phase ratio is Nd 30 Dy 16 B 1.0Co 10 Cu 5 Fe 38. After smelting, the ingot casting process is used for cooling, hydrogen crushing, and jet milling. After that, the main phase and neodymium-rich phase powder are mixed in a ra...

Embodiment 3

[0035] A formula is prepared as Nd 28 Pr 1.8 B 1.2 Ga 0.2 Nb 0.4 Fe 68.4. Firstly, the existing stripping process is adopted, and the raw materials are smelted and stripped according to the above ratio. The main phase is formed at the same time as Nd-rich, and then The main phase and neodymium-rich phase alloy are subjected to hydrogen crushing, jet milling, magnetic field orientation, pressing, sintering and tempering.

[0036] Then adopt the method described in the present invention to make a magnet: the main phase and the Nd-rich phase are designed separately, the raw material ratio of the main phase is Nd28 B 1.2 Fe70.8, and after smelting, it is cooled by strip-spinning process, hydrogen crushing, and air-flow milling; The ratio of Nd 28 Pr 22.5 B 1.2 Ga 2.5 Nb 5 Fe40.8 is Nd 28 Pr 22.5 B 1.2 Ga 2.5 Nb 5 Fe40.8. After smelting, the ingot casting process is used for cooling, hydrogen crushing, and jet milling, and then the main phase and Nd rich phase powder are mixed accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com