Laser cutter

A technology of laser cutting machine and main engine, applied in laser welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of high maintenance cost, difficult installation, waste of time, etc., achieve safe and reliable operation, and improve production efficiency , to ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

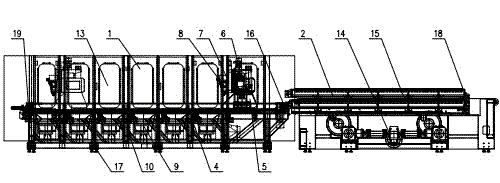

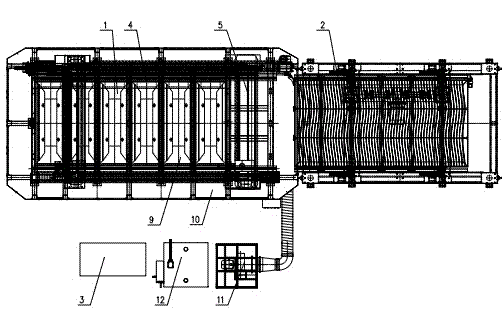

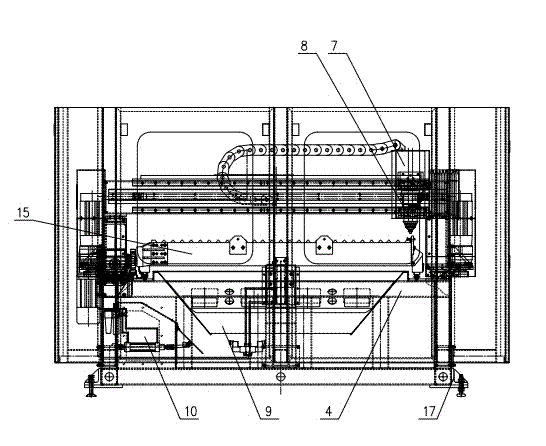

[0037] Such as Figure 1 to Figure 3 As shown, the laser cutting machine of the present invention is composed of a host workbench device 1 and an adjacent rack device 2 , and is controlled by a numerical control system 3 . The host workbench device 1 includes an integrated workbench 4, and left and right linear guide rails are arranged on the front of the workbench 4. The beam assembly 5 straddles the left and right linear guide rails and can slide along the guide rail in the X-axis (longitudinal direction) , the crossbeam assembly 5 is provided with a lateral movement assembly 6 that can realize the Y-axis (horizontal) sliding along the horizontal axis, and the fiber laser cutting head 8 realizes the Z-axis (vertical) sliding through the height lifting assembly 7. Fiber laser cutting The head 8 is connected to a fiber laser power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com