Method for producing organic fertilizer by utilizing fermentation packing in cage culture layer house

A technology for fermenting bedding material and organic fertilizer, which is applied in the field of manufacturing organic fertilizer, can solve the problems of increased transportation cost, pollution of feces of laying hens, and inability to be transported out, so as to improve the internal environment of the chicken house, solve the problem of difficult treatment, and improve the environment of the chicken house. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

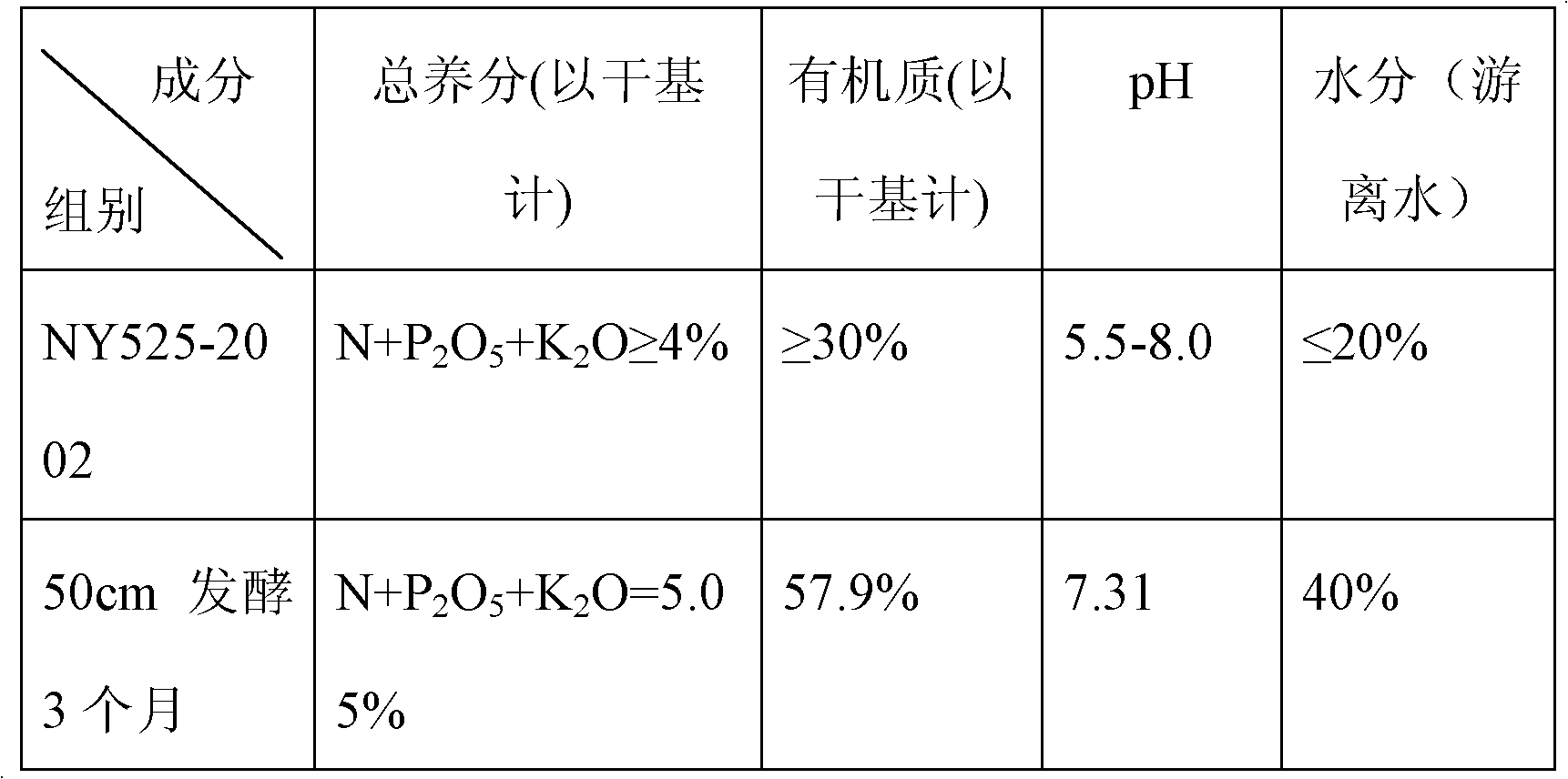

[0020] Embodiment 1 Winter 50cm thick litter is carried out organic fertilizer production in the chicken coop

[0021] 1 The process flow of organic fertilizer production is

[0022] 1.1 Mix the prepared dry sawdust with a water content of 8-10% and dry rice husk with a water content of 8-10% according to the mass ratio of 1:1 and place them in the place where fermentation is required, and then add 65% water content to it The fresh chicken manure; The weight parts of described dry sawdust, dry rice husk and fresh chicken manure are respectively dry sawdust 43.7, dry rice husk 43.7, fresh chicken manure 12.6;

[0023] 1.2 Dissolving the fermentation strain Bacillus subtilis in water, the addition of said Bacillus subtilis is 0.12% of the water quality (live bacteria content > 10 8 each / ml water); then the water that is dissolved with Bacillus subtilis is added in the material of step 1.1; The mass ratio of described water and material is 1: 1;

[0024] 1.3 Mix the materials a...

example 2

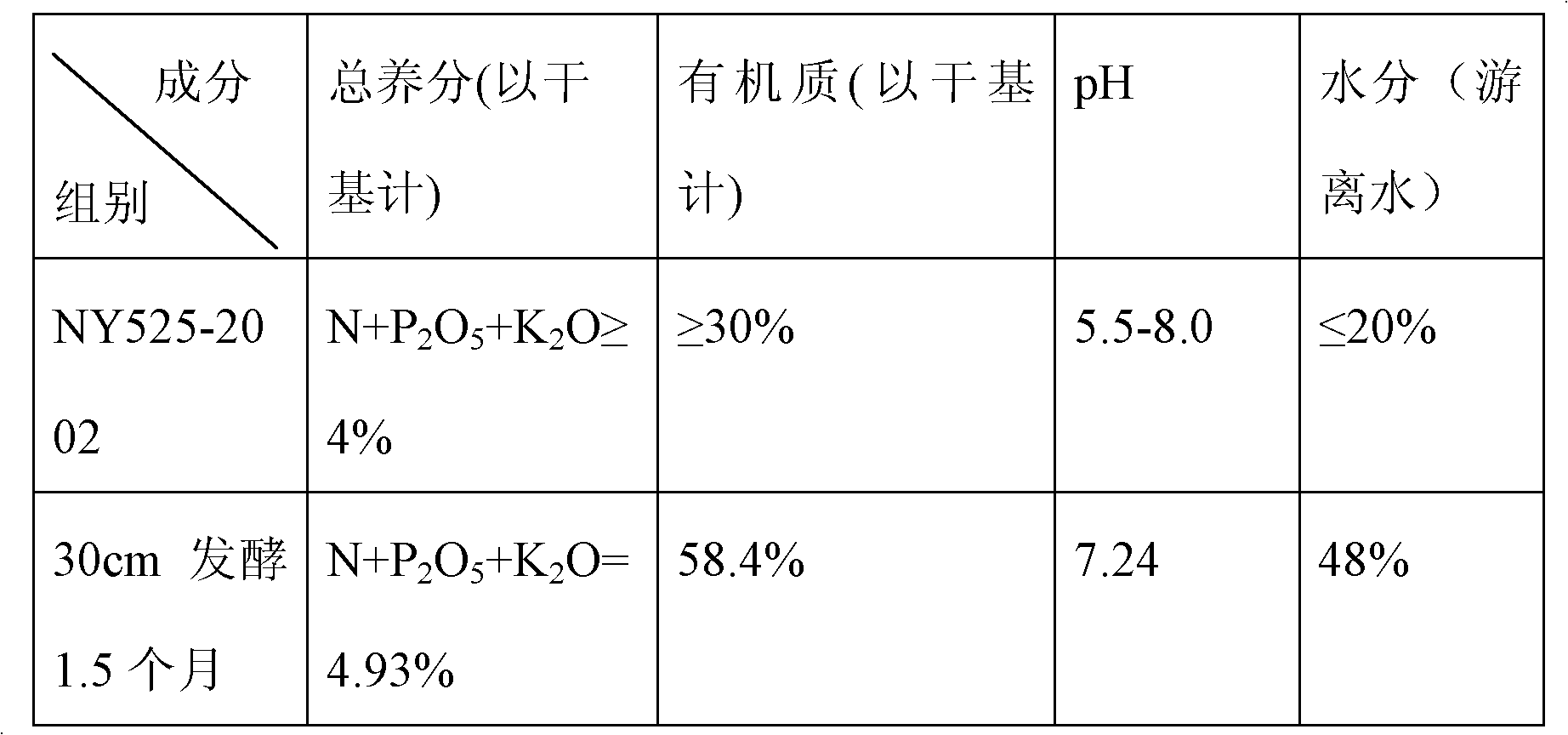

[0033] Example 2: Organic fertilizer production in a 30cm-thick bedding cage chicken coop in summer

[0034] 2 The process flow of organic fertilizer production is

[0035] 2.1 Mix the prepared dry sawdust with a water content of 9% and the dry rice husk with a water content of 9% according to a mass ratio of 1:1 and place them in the place where fermentation is required, and then add fresh chicken manure with a water content of 75% to it The parts by weight of described dry sawdust, dry rice husk and fresh chicken manure are respectively dry sawdust 45, dry rice husk 45, and fresh chicken manure 10;

[0036] 2.2 Dissolving the fermentation strain Bacillus subtilis in water, the addition amount of said Bacillus subtilis is 0.15% of the water quality (live bacteria content > 10 8 each / ml water); then the water that is dissolved with Bacillus subtilis is added in the material of step 2.1; The mass ratio of described water and material is 1: 1;

[0037] 2.3 Mix the materials an...

example 3

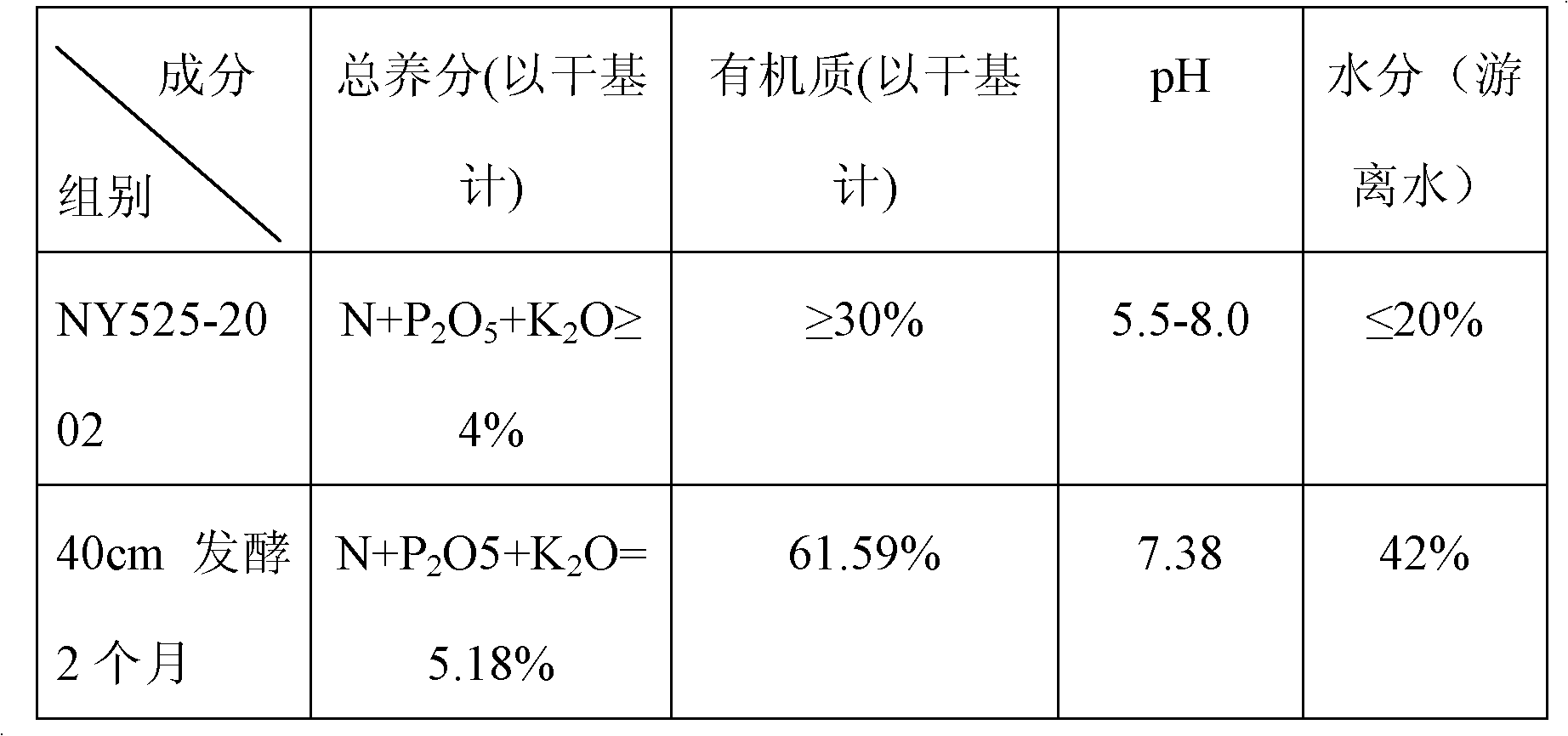

[0046] Example 3: 40cm thick litter in spring and autumn

[0047] 3 The process flow of organic fertilizer production is

[0048] 3.1 Mix the prepared dry sawdust with a water content of 9.5% and dry rice husk with a water content of 9.5% according to a mass ratio of 1:1 and place them in the place where fermentation is required, and then add fresh chicken manure with a water content of 68% The parts by weight of described dry sawdust, dry rice husk and fresh chicken manure are respectively dry sawdust 43.5, dry rice husk 43.5, fresh chicken manure 13;

[0049] 3.2 Dissolving the fermentation strain Bacillus subtilis in water, the addition of said Bacillus subtilis is 0.18% of the water quality (live bacteria content > 10 8 each / ml water); then the water that is dissolved with Bacillus subtilis is added in the material of step 3.1; The mass ratio of described water and material is 1: 1;

[0050] 3.3 Mix the materials and water evenly, and pile them together; when the accumul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com