Chloroprene rubber/nature rubber for skirt of hovercraft and manufacturing method of chloroprene rubber/nature rubber

A technology of natural rubber and hovercraft, which is applied in the field of rubber formulation to achieve the effect of improving adhesive strength and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

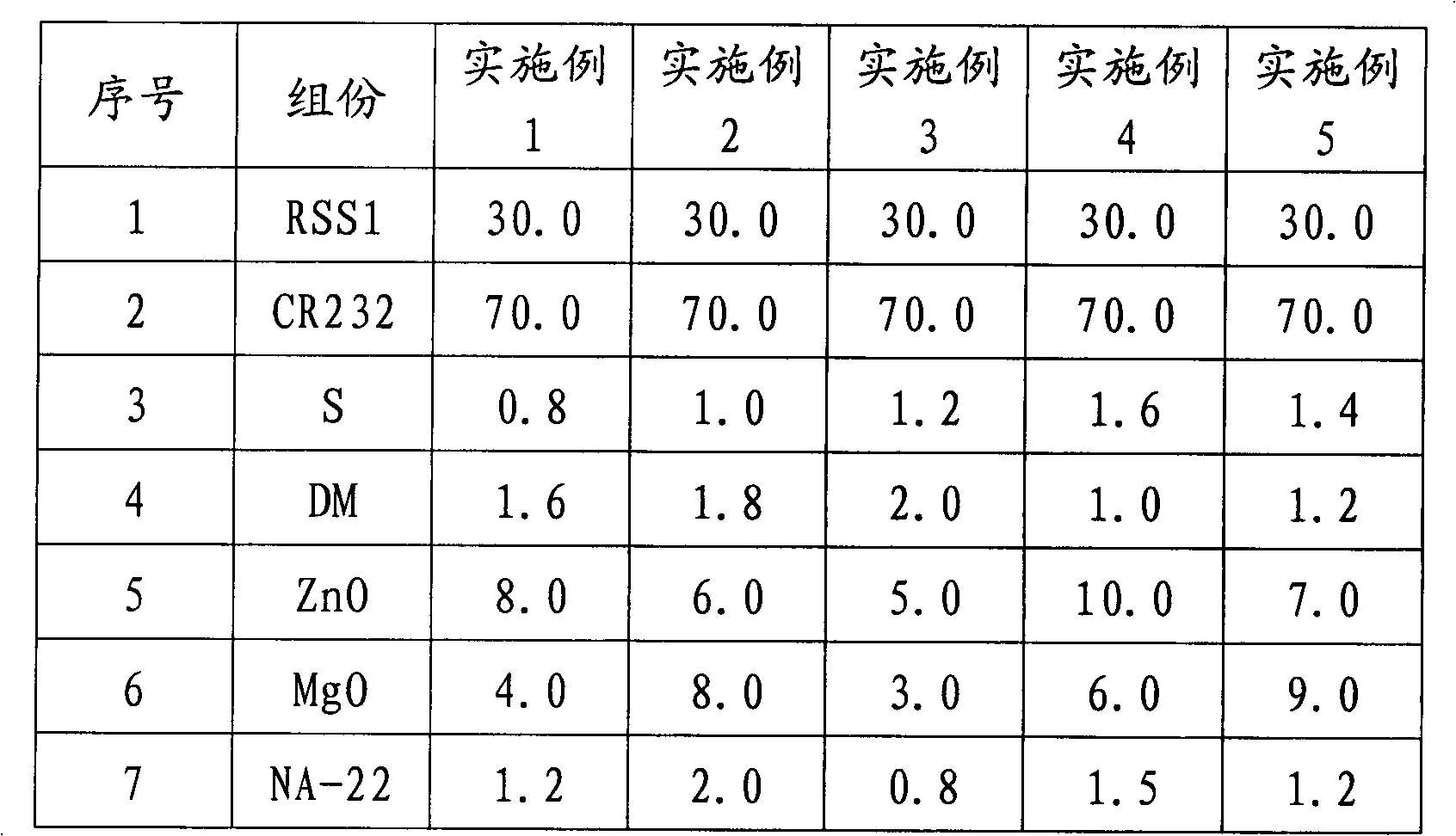

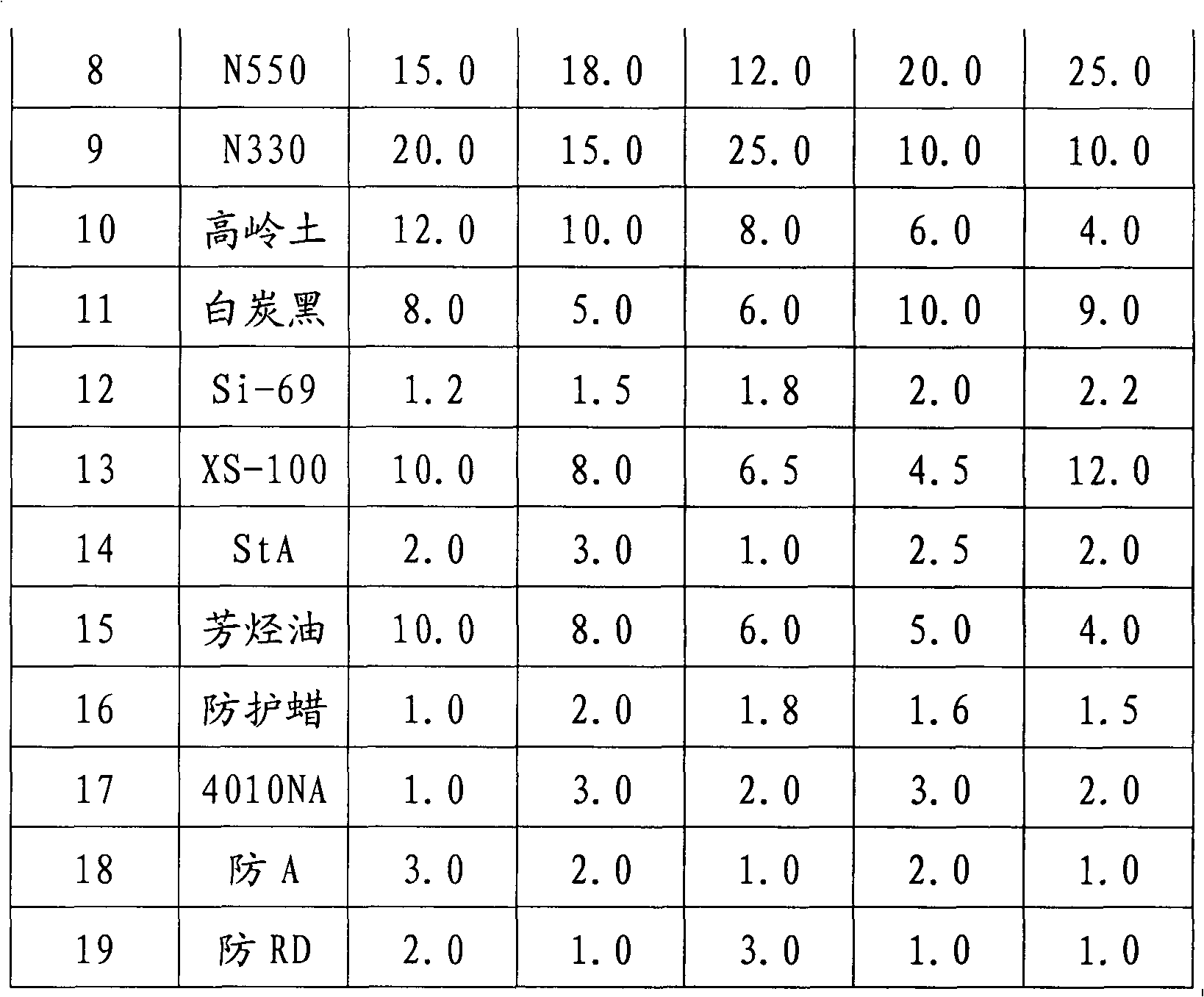

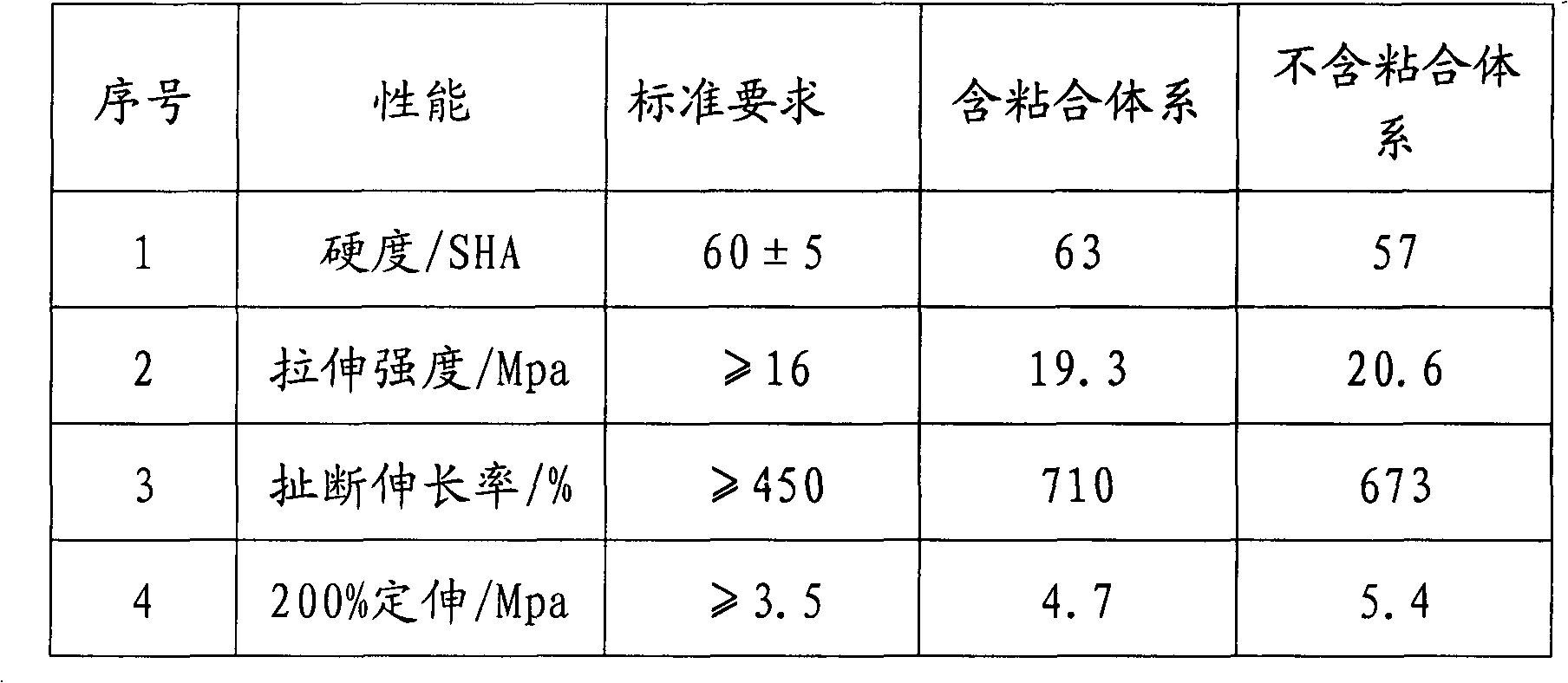

[0061] A hovercraft apron is implemented according to the following formula with neoprene:

[0062] In parts by weight:

[0063]

[0064]

[0065] Said antioxidant 4010NA is N-isopropyl-N`-phenyl-p-phenylenediamine;

[0066] Said anti-aging agent RD is anti-aging agent 212,4-trimethyl-1,2-dihydroquinoline;

[0067] Said antioxidant A is N-phenyl-α-naphthylamine;

[0068] Said accelerator DM is dithiodibenzothiazole;

[0069] The accelerator NA-22 is 1,-2 ethylenethiourea.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com