Scale-reducing additive for automatic dishwashing systems

一种自动、洗涤剂的技术,应用在洗涤剂配合剂、洗涤剂组合物、非表面活性洗涤剂组合物等方向,能够解决没有揭示聚合物组合物等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

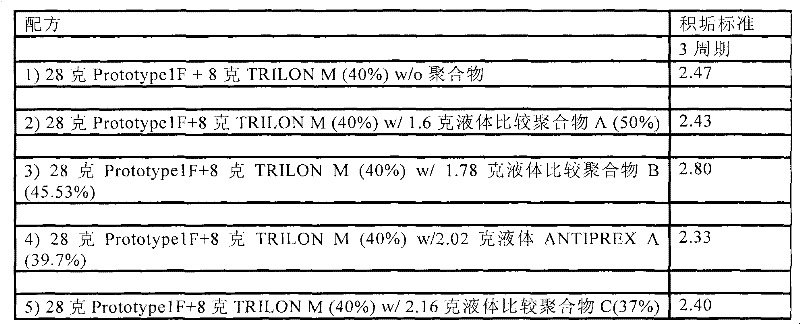

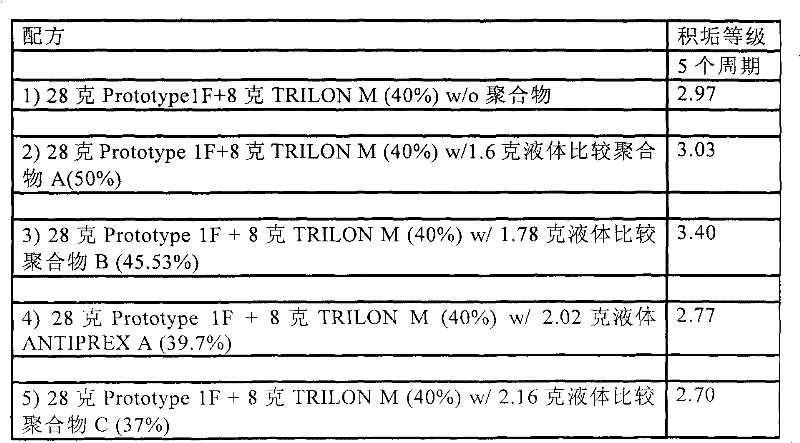

[0024] polymer testing - The scale-reducing properties of all polymers were determined by mixing these polymers with "Prototype 1F" as described below, in a KENMORE QUIETGUARD dishwashing machine (addition of solids during the main wash cycle), using a hardness of 400ppm (2:1 Ca +2 : Mg +2 ) water for five cycles at 130°F (54.4°C), food-free. Glasses were evaluated after 3 and 5 cycles according to ASTM method 3556-85 (1 = clean, 5 = thick film).

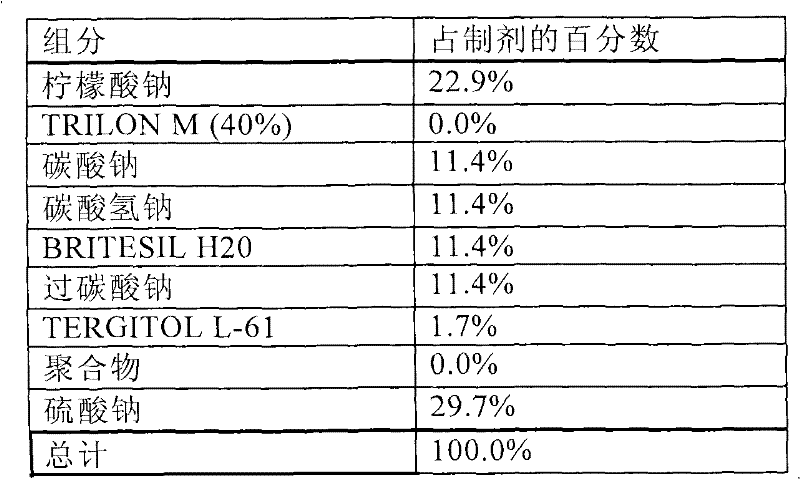

[0025] result - In each experiment, 3.2 g of active trisodium methylglycine diacetate were added together with 28 g of formulation Prototype 1F.

[0026]

[0027] TRILON M is an aqueous solution of trisodium methylglycine diacetate available from BASF Corp.

[0028]

[0029]

[0030] Polymer samples:

[0031] Comparative polymer A (Mw = 2220) = 90% acrylic acid / 10% maleic acid, sodium salt phosphono end groups.

[0032] Comparative Polymer B (Mw=7,201) 100% acrylic polymer containing sulfonate end groups.

[0033...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com