Stepless adjustment device for air quantity of reciprocating compressor intake valve

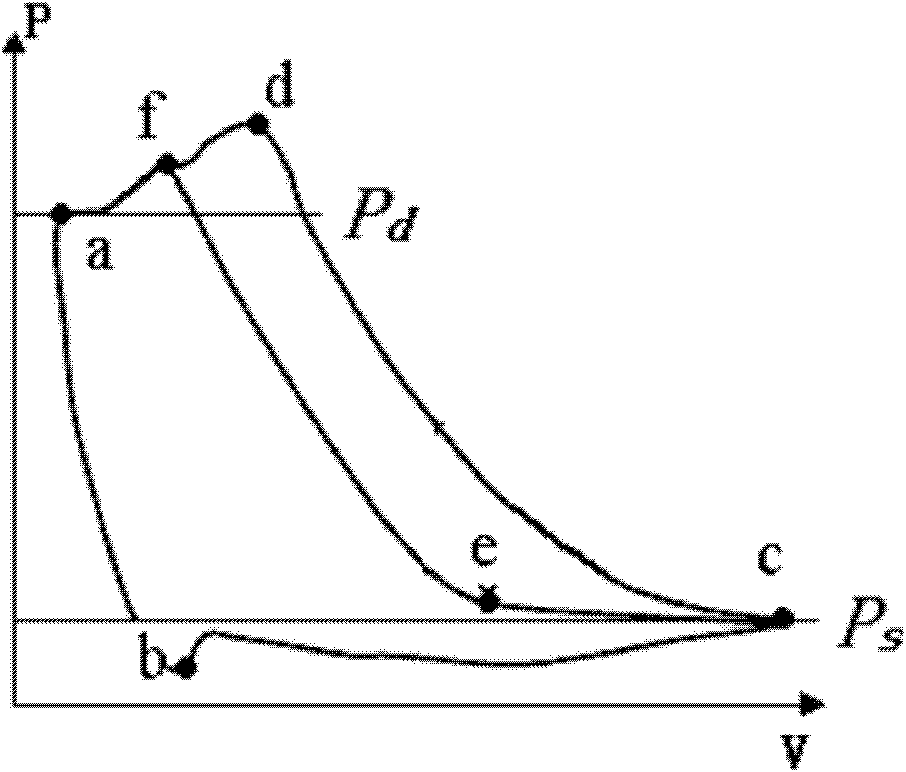

A technology of stepless adjustment and compressor, which is applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc. It can solve problems such as numerous transmission components, complex device structure, and air valve impact, and achieve system simplification, Effects of improving reliability and reducing flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

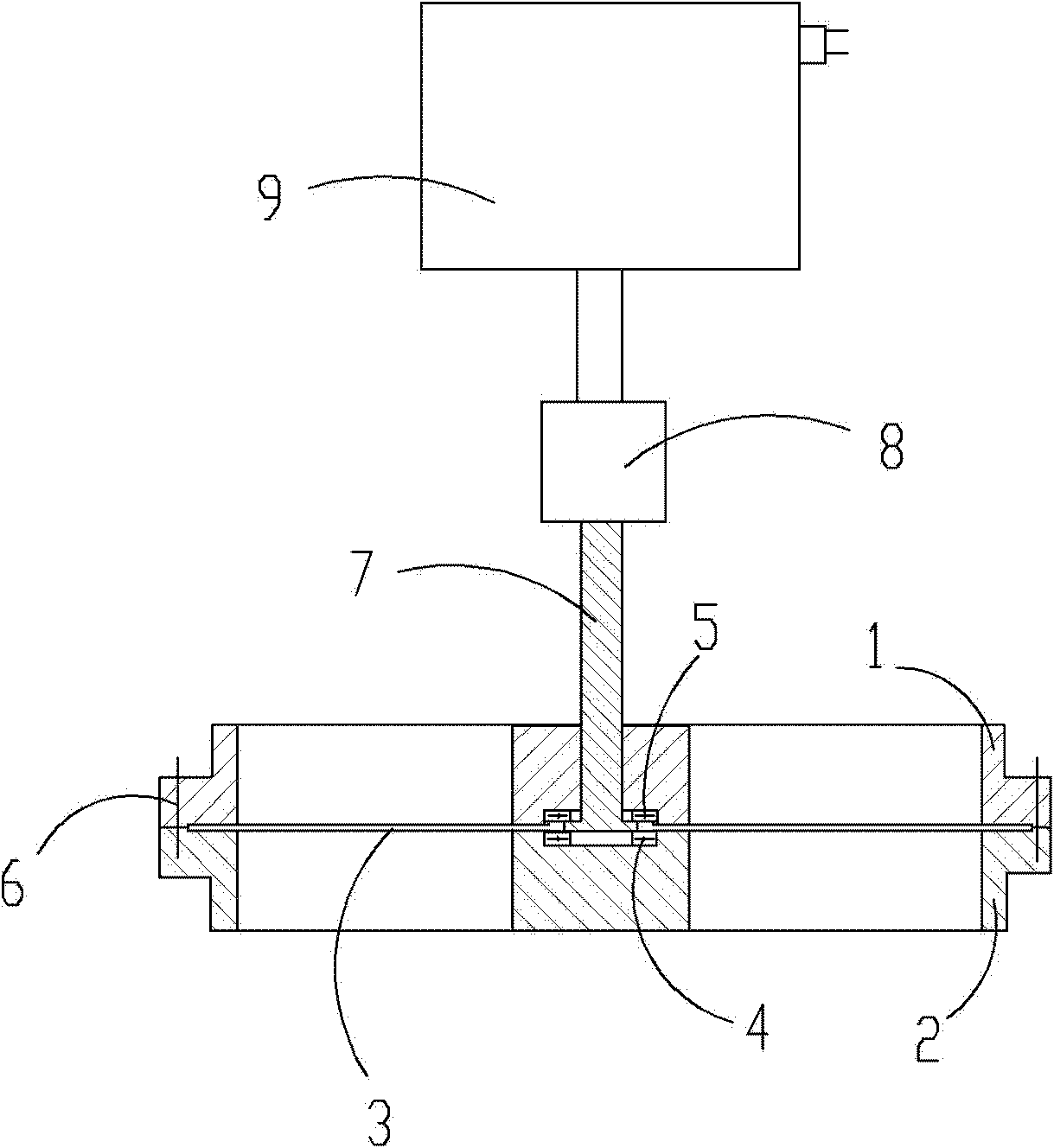

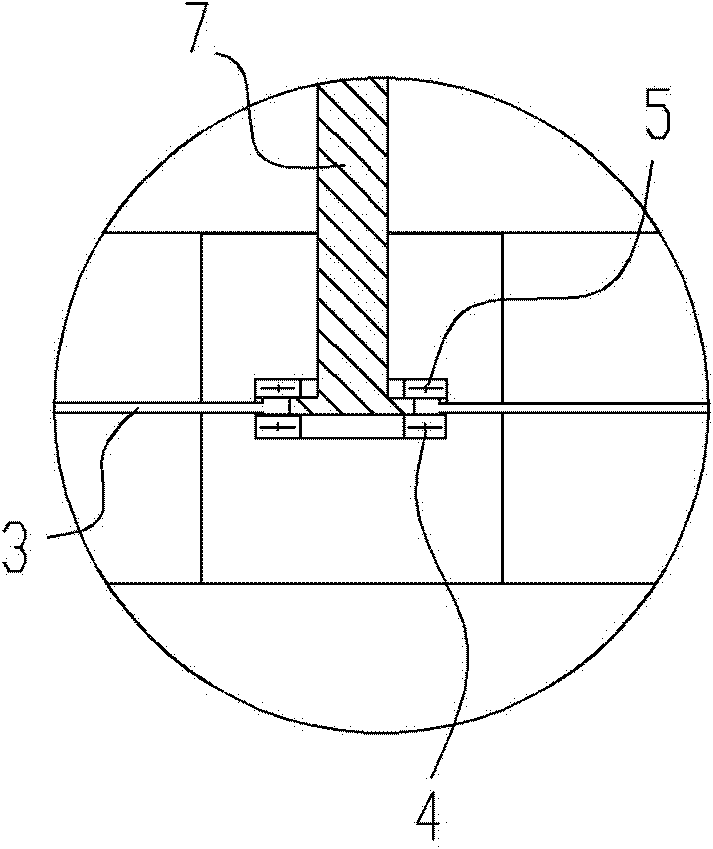

[0024] see Figure 2a and Figure 2b , in the present embodiment, fixedly connected to the bottom end of the transmission shaft 7 and driven by the transmission shaft 7 is a rotary valve plate 3 that is arranged in a “T” shape with the transmission shaft 7, and the rotary valve plate 3 is located between the upper seat 1 and the base. 2, between the rotary valve plate 3 and the upper seat 1 and the base 2 are coaxially matched; the output shaft of the stepping motor 9 is connected with the transmission shaft 7 through a coupling 8, and the bottom end of the transmission shaft 7 is fixedly arranged on the rotating In the central hole 12 of the valve plate 3;

[0025] image 3 As shown, the rotary valve plate 3 is separated from the valve plate fan surface 10 and the valve plate fan hole 11, with its fan hole 11 as the flow channel, and the outer edge is the valve plate edge 13. This structure can obtain the largest circulation area;

[0026] Such as Figure 4 and Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com