Combined high-temperature phase-transition heat storage system

A high-temperature phase change, heat storage system technology, applied in the direction of heat storage equipment, heat exchange equipment, heat exchanger types, etc., to achieve the effect of wide range of use, strong applicability, and easy amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

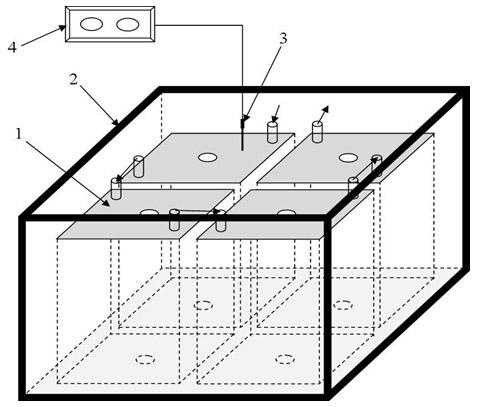

Embodiment 1

[0026] Weigh 40kg of inorganic salt phase change material lithium chloride (LiCl) with an electronic scale, load M=10kg lithium chloride (LiCl) into each high temperature phase change heat storage core 1, and then put 4 high temperature phase change heat storage cores The thermal core 1 is put into the heat preservation structure 2, and the figure 1 As shown in the heat storage system, then put the temperature measuring end of the thermocouple 3 on the ceramic protection tube and insert it into the phase change material of the high-temperature phase change heat storage core 1, and connect the other end of the thermocouple 3 to the temperature controller 4, and cover it Insulation cover. Set the upper limit temperature of the temperature controller, turn on the power supply of the heating element, and heat the device. When the temperature reaches a certain temperature above the phase change temperature of the phase change material, the heating is stopped, and the total heat st...

Embodiment 2

[0028] Take by weighing 24kg sodium carbonate (Na 2 CO 3 ) and 16kg lithium carbonate (Li 2 CO 3 ) Inorganic salt phase change material, each high temperature phase change heat storage core 1 is filled with m 1 =6kg sodium carbonate (Na 2 CO 3 ) and m 2 =4kg lithium carbonate (Li 2 CO 3 ) mixed inorganic salts evenly, and then put 4 high-temperature phase change heat storage cores 1 into the heat preservation structure 2 to form figure 1 As shown in the heat storage system, the temperature measuring end of the thermocouple 3 is covered with a ceramic protection tube and inserted into the phase change material, the other end of the thermocouple 3 is connected to the temperature controller 4, and the heat preservation cover is covered. Set the upper limit temperature of the temperature controller, turn on the power supply of the heating element, and heat the material. When the temperature reaches a certain temperature above the phase change temperature of the phase chan...

Embodiment 3

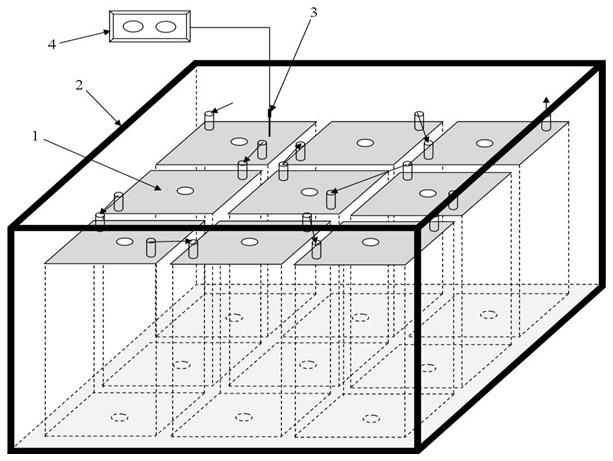

[0030] Take by weighing 54kg sodium carbonate (Na 2 CO 3 ) and 36kg lithium carbonate (Li2 CO 3 ) Inorganic salt phase change material, each high temperature phase change heat storage core 1 is filled with m 1 =6kg sodium carbonate (Na 2 CO 3 ) and m 2 =4kg lithium carbonate (Li 2 CO 3 ) mixed inorganic salts evenly, and then put 9 high-temperature phase change heat storage cores 1 into the heat preservation structure 2 to form figure 2 As shown in the heat storage system, the temperature measuring end of the thermocouple 3 is covered with a ceramic protection tube and inserted into the phase change material, the other end of the thermocouple 3 is connected to the temperature controller 4, and the heat preservation cover is covered. Set the upper limit temperature of the temperature controller, turn on the power supply of the heating element, and heat the phase change heat storage core. When the temperature reaches a certain temperature above the phase change temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com