Preparation method of macroporous cross-linked sodium alginate gel beads

A technology of sodium alginate, gel ball, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

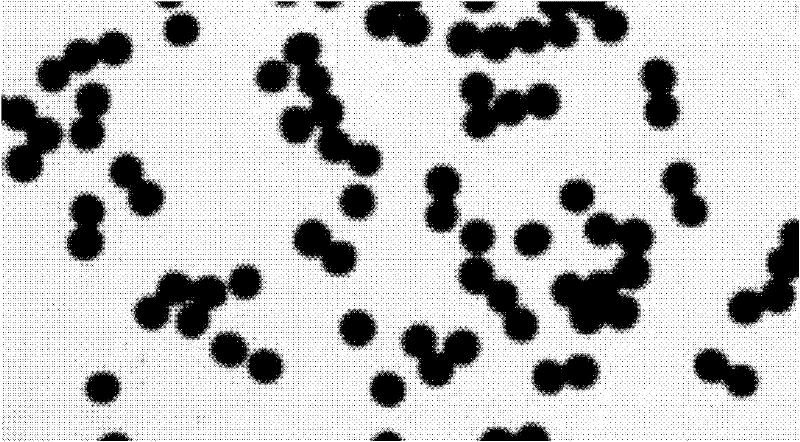

Method used

Image

Examples

Embodiment 1

[0024] Step 1: Dissolve 8g of sodium alginate and 32g of sodium sulfate in 400mL of deionized water.

[0025] The second step: drop the above solution into 500ml of 5% calcium chloride solution through a 0.5mm pinhole, and stir the calcium chloride solution at the same time. After the dropwise addition was complete, it was stirred for 8 hours.

[0026] The third step: filter the alginic acid gel prepared in the second step with gauze, and wash it with ethanol.

[0027] Step 4: Measure 50mL of the above-mentioned alginic acid gel balls into a 250mL three-necked flask, add 50mL of epichlorohydrin and 5g of NaOH, stir, raise the temperature to 60°C, and react for 8 hours. Cool to room temperature, filter out the cross-linked alginate gel balls with gauze, and wash with ethanol.

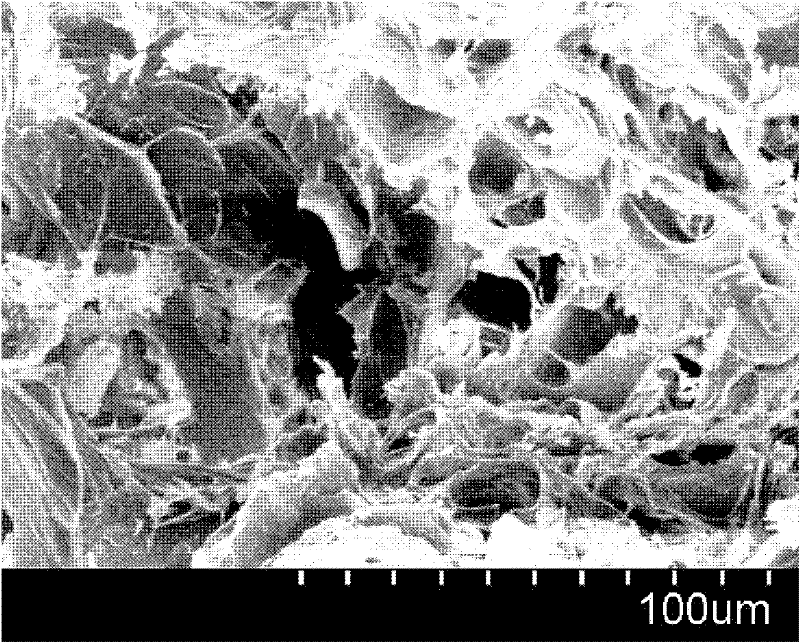

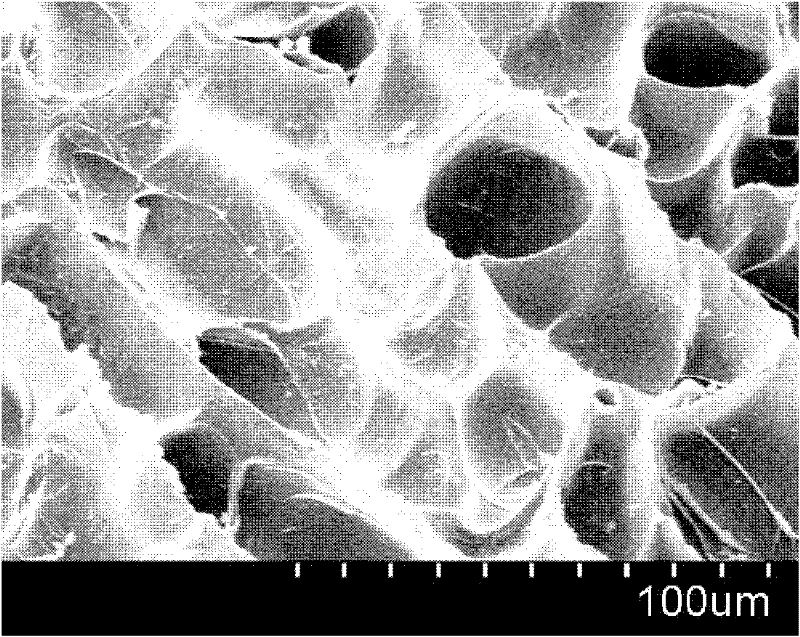

[0028] Step 5: Place the cross-linked alginic acid gel balls prepared above in 100 mL of 0.1M EDTA solution for 4 hours to dissolve the calcium sulfate in the cross-linked alginic acid gel balls, and r...

Embodiment 2

[0037] Step 1: Dissolve 8g of sodium alginate and 16g of sodium sulfate in 400mL of deionized water.

[0038] The second step: drop the above solution into 500ml of 5% calcium chloride solution through a 0.5mm pinhole, and stir the calcium chloride solution at the same time. After the dropwise addition was complete, it was stirred for 8 hours.

[0039] The third step: filter the alginic acid gel prepared in the second step with gauze, and wash it with ethanol.

[0040] Step 4: Measure 50mL of the above-mentioned alginic acid gel balls into a 250mL three-necked flask, add 50mL of epichlorohydrin and 5g of NaOH, stir, raise the temperature to 60°C, and react for 8 hours. Cool to room temperature, filter out the cross-linked alginate gel balls with gauze, and wash with ethanol.

[0041] Step 5: Place the cross-linked alginic acid gel balls prepared above in 100 mL of 0.1M EDTA solution for 4 hours to dissolve the calcium sulfate in the cross-linked alginic acid gel balls, and r...

Embodiment 3

[0047] Step 1: Weigh 8g of sodium alginate and dissolve it in 400mL of deionized water.

[0048] The second step: drop the above solution into 500ml of 5% calcium chloride solution through a 0.5mm pinhole, and stir the calcium chloride solution at the same time. After the dropwise addition was complete, it was stirred for 8 hours.

[0049]The third step: filter the alginic acid gel prepared in the second step with gauze, and wash it with ethanol.

[0050] Step 4: Measure 50mL of the above-mentioned alginic acid gel balls into a 250mL three-necked flask, add 50mL of epichlorohydrin and 5g of NaOH, stir, raise the temperature to 60°C, and react for 8 hours. Cool to room temperature, filter out the cross-linked alginate gel balls with gauze, and wash with ethanol.

[0051] Step 5: Place the cross-linked alginic acid gel balls prepared above in 100 mL of 0.1M EDTA solution for 4 hours to dissolve the calcium sulfate in the cross-linked alginic acid gel balls, and repeat the oper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com