Rectification grille for protecting fly ash particles on catalyst layer of SCR (Semiconductor Control Rectifier) denitration device

A technology of rectification grid and catalyst layer, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of not improving the optimization design of rectifying grid, and not proposing CFD quantitative calculation of flue gas fly ash particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

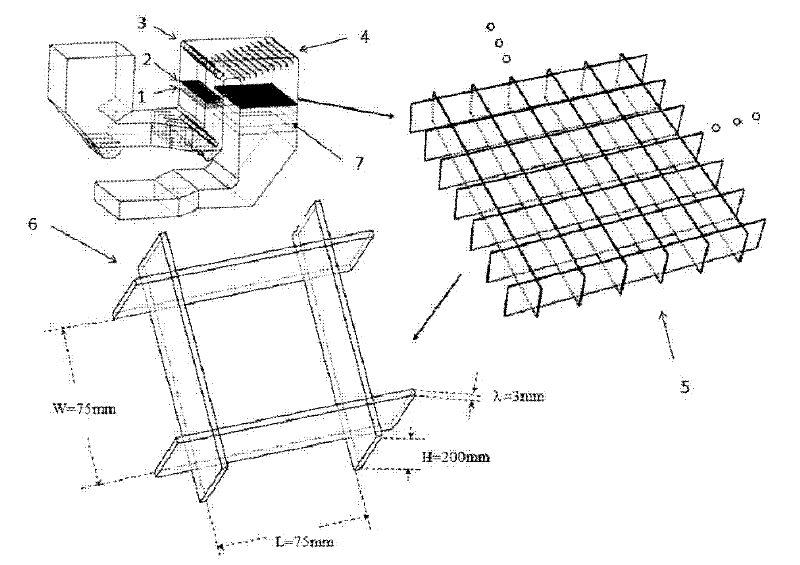

[0020] like figure 1 and figure 2 As shown, it is the overall flue and rectifying grille part of the SCR denitrification device of a 300MW thermal power station, and the outer wall size of the flue is 15750×11400×200mm.

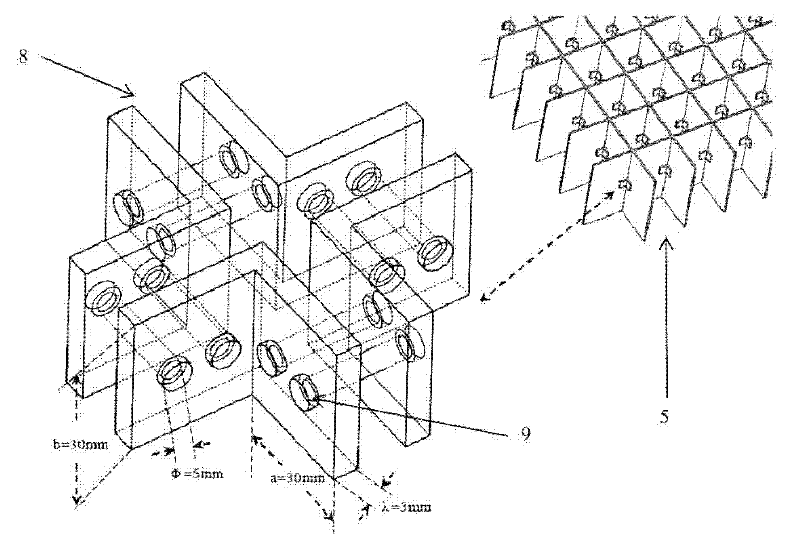

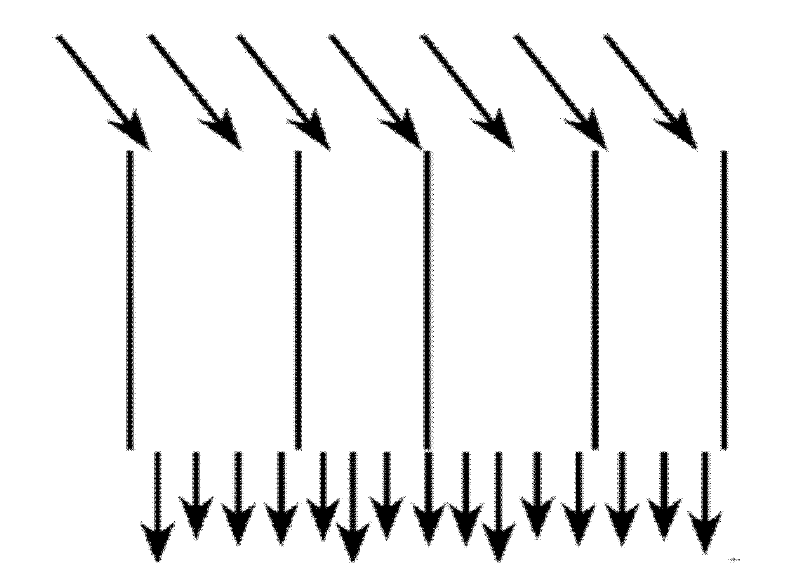

[0021] The rectifying grid 5 described in this embodiment is located at the 5mm-10mm place on the upper surface of the catalyst layer 7 and is composed of several cuboid grid units 6. It is composed of L-shaped angle iron 8; the rectifying grid is fixedly supported on the wall of the flue of the SCR denitrification system by the grid support beam.

[0022] The L-shaped angle iron 8 in the cub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com