Device for generating electricity by using dead steam discharged by steam turbine

A steam outlet and turbine technology, used in energy-saving projects and waste heat utilization, can solve problems such as system equipment corrosion, achieve high thermal energy quality, reduce costs, and simplify equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

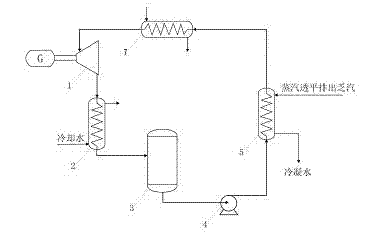

[0029] According to the present invention, a device for generating electricity by exhausting exhaust steam from steam turbine 6 has a structure as follows: figure 1 As shown, it includes a liquid ammonia storage tank 3, a booster pump 4, an evaporator 5, a turbine 1 and a condenser 2; wherein, the turbine 1 is composed of a turbine and a generator connected to the turbine.

[0030] The inlet of the liquid ammonia storage tank 3 is connected with the outlet of the condenser 2, and the outlet of the liquid ammonia storage tank 3 is connected with the liquid ammonia inlet of the evaporator 5 through the booster pump 4, and the evaporator 5 The liquid ammonia steam outlet is connected with the inlet of turbine 1, and the outlet of said turbine 1 is connected with the inlet of said condenser 2, forming a closed circuit;

[0031] The heating circuit of the evaporator 5 is connected to the exhaust steam outlet of the steam turbine 6, and the exhaust steam exhausted by the steam t...

Embodiment 2

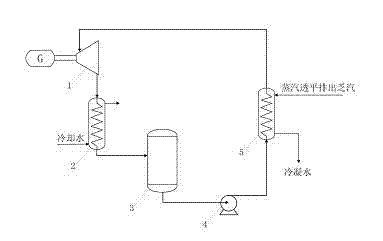

[0036] The structure of a device for generating electricity by using steam turbine 6 to discharge exhaust steam described in this embodiment is different from that of embodiment 1, as figure 2 As shown, a superheater 7 is arranged between the liquid ammonia vapor outlet of the evaporator 5 and the inlet of the turbine 1, and the superheater 7 can make the ammonia vapor entering the turbine 1 to do work have a higher thermal energy quality, thereby being able to Improve the overall thermal energy utilization efficiency of the power generation system. The heat source of the superheater may be waste flue gas with heat energy from a power plant.

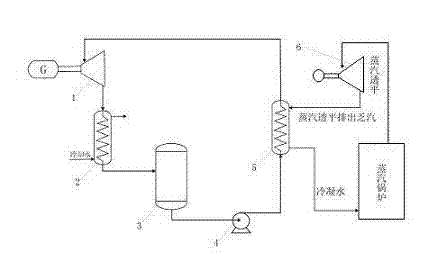

[0037] As a preferred embodiment, such as Figure 4As shown, in this embodiment, the condensed water outlet of the heating circuit of the evaporator 5 is connected to the water inlet of the steam boiler, and the outlet of the steam boiler is connected to the steam inlet of the steam turbine.

[0038] The exhaust steam exhausted by the...

Embodiment 3

[0043] The structure of a device for generating power by exhausting exhaust steam from the steam turbine 6 described in this embodiment is the same as that in Embodiment 2.

[0044] The exhaust steam exhausted by the steam turbine 6 has a pressure of 0.85MPa and a temperature of 95°C.

[0045] In this embodiment, the power of the generating set is 300 MW, the exhaust steam flow rate is 950 t / h, and the liquid ammonia circulation rate is 1800 t / h.

[0046] When working, the liquid ammonia in the liquid ammonia storage tank 3 is pressurized to 4MPa by the booster pump 4 and sent to the evaporator 5, and the liquid ammonia in the evaporator 5 absorbs the phase change heat of exhaust steam exhausted by the steam turbine 6 and becomes Ammonia vapor with a temperature of 85°C and a pressure of 4MPa; then the ammonia vapor enters turbine 1 to do work, driving a generator to generate 57.3MW; the pressure of ammonia vapor from turbine 1 decreases to 1.5MPa, the temperature drops to 38°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com