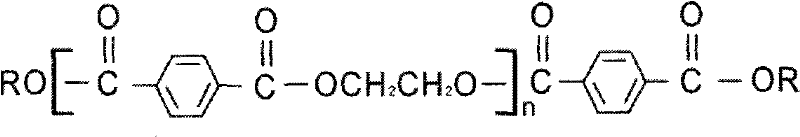

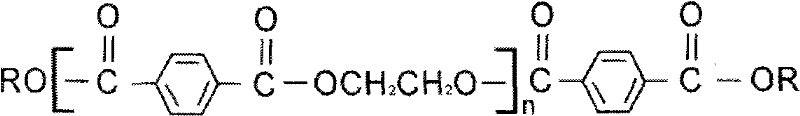

Method for preparing polyvinyl chloride (PVC) plasticizer through ester exchange reaction of waste polyethylene terephthalate (PET) and monohydric alcohol

A monohydric alcohol and transesterification technology, applied in the field of polymer chemistry, can solve the problems of difficult natural degradation, environmental pollution, large amount of waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Implementation 1: Wash the polyethylene terephthalate, spin it dry, then wash it with distilled water, spin it dry, and dry it at 100°C for later use.

[0020] Implementation 2: Take 384 parts of polyethylene terephthalate, 260 parts of octanol and 1 part of zinc compound obtained in Implementation 1, stir under the protection of nitrogen, heat at 180-200°C for 4-9 hours, and polypylene Ethylene glycol diformate dissolves and the reaction is complete. A short-chain polyester compound is obtained, which is off-white soft wax at room temperature. Under the protection of nitrogen, it is a colorless transparent clear liquid.

[0021] Implementation 3: Take 100 parts of polyvinyl chloride resin powder, 60 parts of the product of Implementation 2 and 1.5 parts of stabilizer, stir at 80-100°C to form a loose powder, and press at 180°C to obtain colorless, odorless, soft, Highly transparent polyvinyl chloride product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com