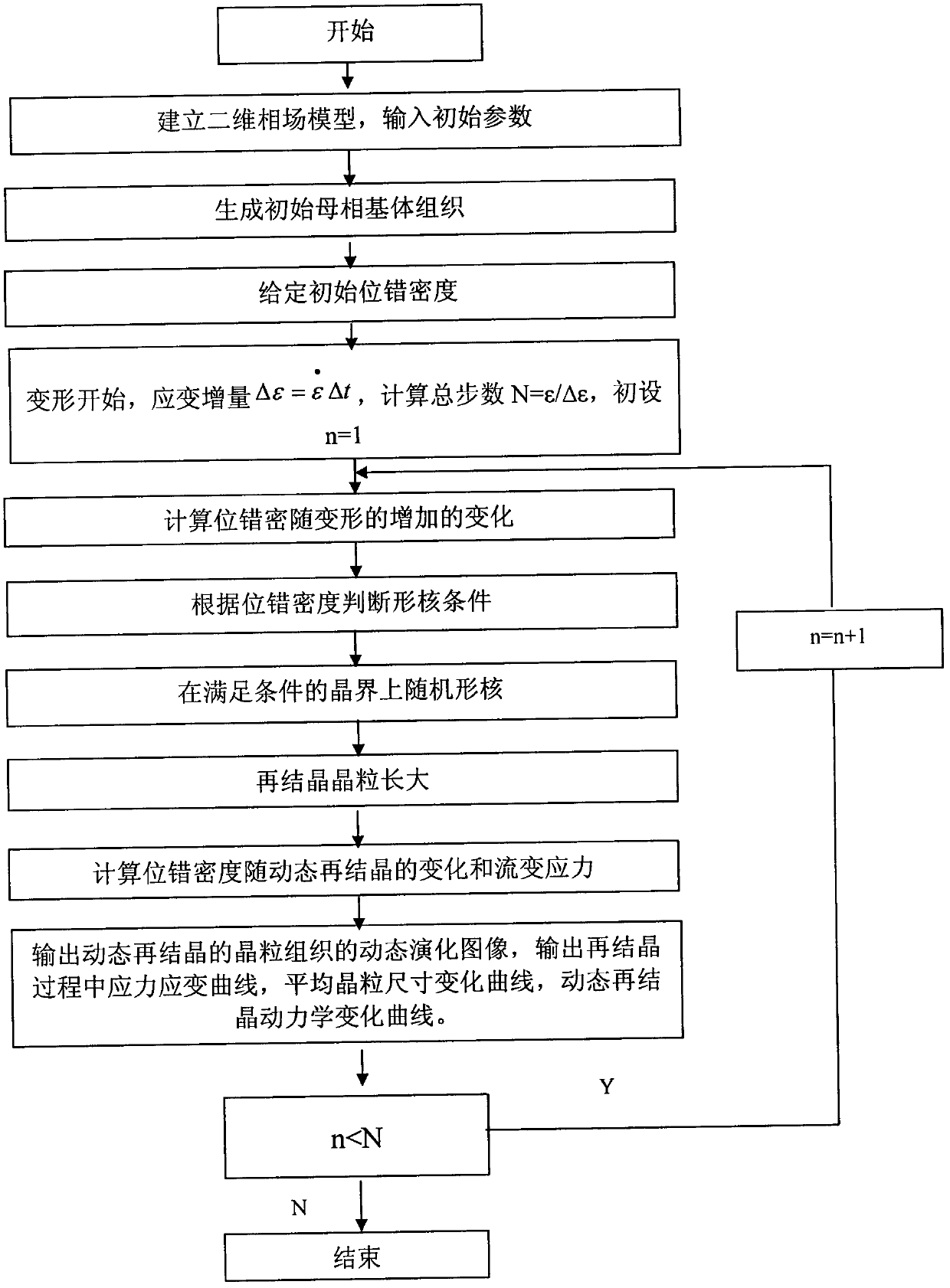

Method for predicting dynamic recrystallization microstructure evolution in thermal deformation process of pure copper

A technology of recrystallization structure and prediction method, applied in the field of metal rolling, can solve the problems of no specific parameters, low reliability, lack of physical meaning of selected parameters, etc., and achieve the effect of saving experimental cost and optimizing structure and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

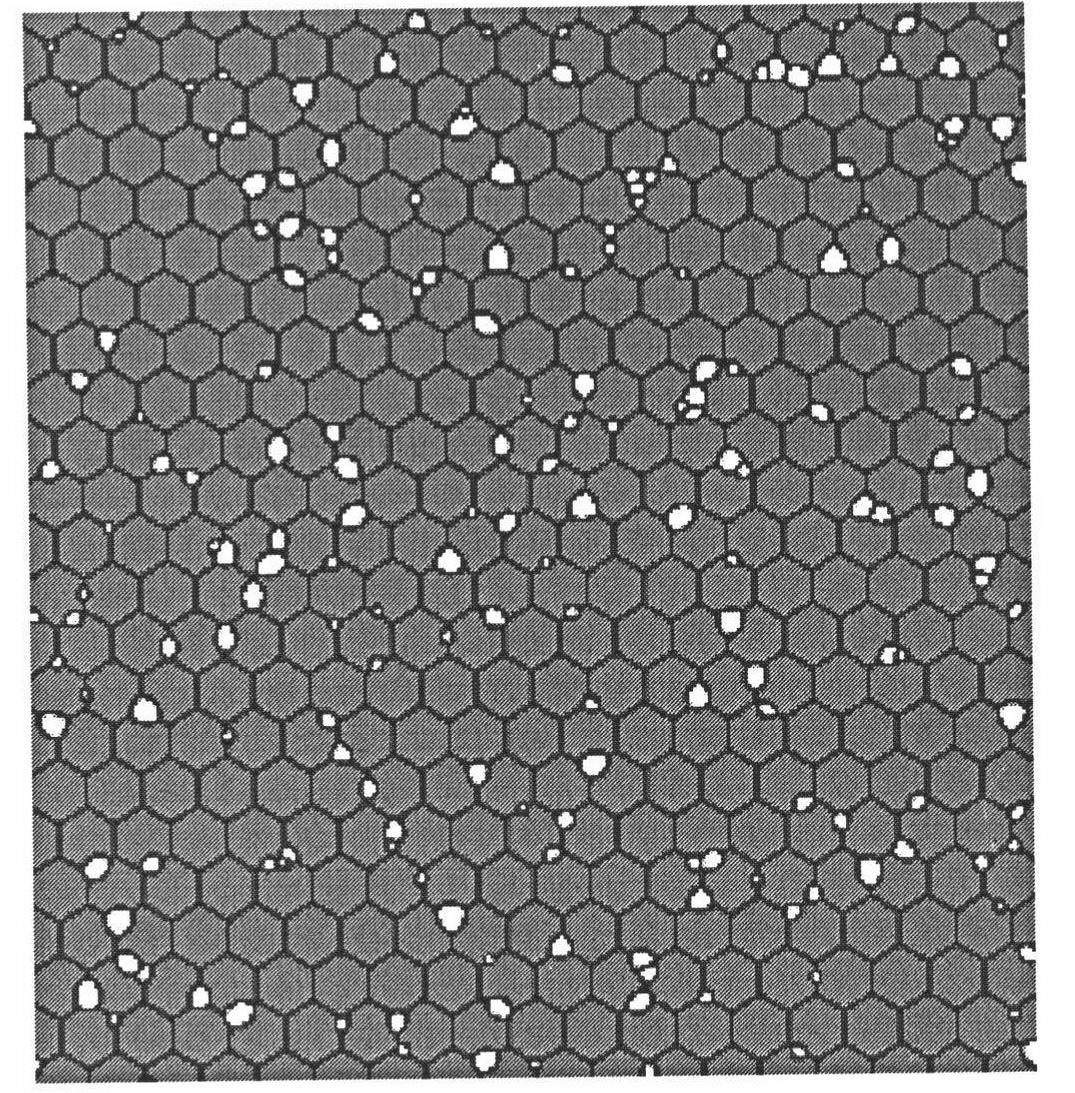

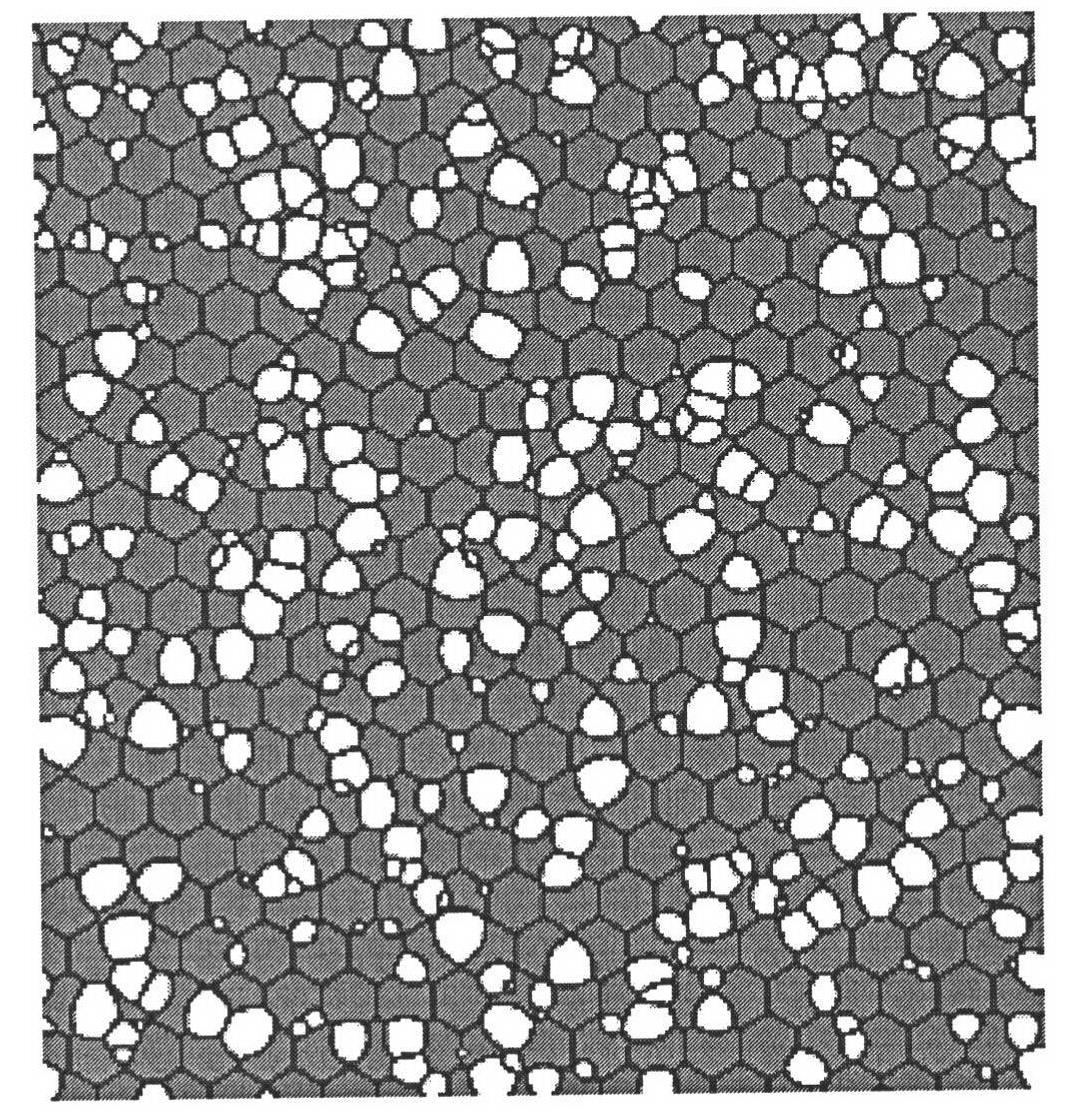

Embodiment 1

[0037] Divide the simulation area of the model of formula (1) into a two-dimensional space of 1045×1101, and the entire simulation area represents a sample size of 0.5225mm×0.5505mm. Select parameter interface energy γ=0.208J / m 2 , M 0 =0.139m 4 K / Js, μ=42.1GPa, activation energy Qa=275KJ / mol, activation energy Q b =110KJ / mol, c=5.0×10 25 , d=1, temperature T=800k, strain rate Then, the regular regular hexagonal initial parent phase matrix grain structure with an average radius of 13.56 μm was calculated by the program. The initial dislocation density ρ is given for each grain ini =1.0×10 9 / m 2 , use an array P to store the phase field value of each grain, and use another array Q to store the number of each grain. After the initial state is given, stress and deformation are applied, the total number of calculation steps is 19200, and the change of dislocation density is calculated by formula (3). When the dislocation density reaches the critical value ρ c =5.5×10 ...

Embodiment 2

[0039]Divide the simulation area of the model of formula (1) into a two-dimensional space of 913×769, and the entire simulation area represents a sample size of 0.4565mm×0.3845mm. Select parameter interface energy γ=0.208J / m 2 , M 0 =0.139m 4 K / Js, μ=42.1GPa, activation energy Qa=275KJ / mol, activation energy Q b =110KJ / mol, c=5.0×10 25 , d=1, strain rate The deformation temperatures are respectively selected as 750K, 800K, 850K and 950K. Then, the regular regular hexagonal initial parent phase matrix grain structure with an average radius of 116.62 μm was calculated by the program. The initial dislocation density ρ is given for each grain ini =1.0×10 9 / m 2 , use an array P to store the phase field value of each grain, and use another array Q to store the number of each grain. After the initial state is given, stress and deformation are applied, the total number of calculation steps is 19200, and the change of dislocation density is calculated by formula (3). When ...

Embodiment 3

[0041] Divide the simulation area of the model of formula (1) into 913×769, 1065×1025, 1065×897 and 1045×1101 two-dimensional space respectively, and the whole simulation area represents 0.4565mm×0.3845mm, 0.5325×0.5125mm, 0.5325mm× 0.4485mm and 0.5225mm×0.5505mm sample size. Select parameter interface energy γ=0.208J / m 2 , M 0 =0.139m 4 K / Js, μ=42.1GPa, activation energy Qa=275KJ / mol, activation energy Q b =110KJ / mol, c=5.0×10 25 , d=1, strain rate Temperature T=800K. Then the regular regular hexagonal initial parent phase matrix grain structure with average radii of 13.56 μm, 37.76 μm, 67.34 μm and 116.62 μm was calculated by the program. The initial dislocation density ρ is given for each grain ini =1.0×10 9 / m 2 , use an array P to store the phase field value of each grain, and use another array Q to store the number of each grain. After the initial state is given, stress and deformation are applied, the total number of calculation steps is 19200, and the chan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com