Stand pipe fixing device

A technology for fixing devices and standpipes, applied in the direction of drill pipes, casings, drilling equipment, etc., can solve problems such as cutting and installation difficulties, standpipe swaying, difficult to ensure the safety of standpipe operation, etc., and achieve overall stability and compactness , easy to operate, and improve the effect of operating safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

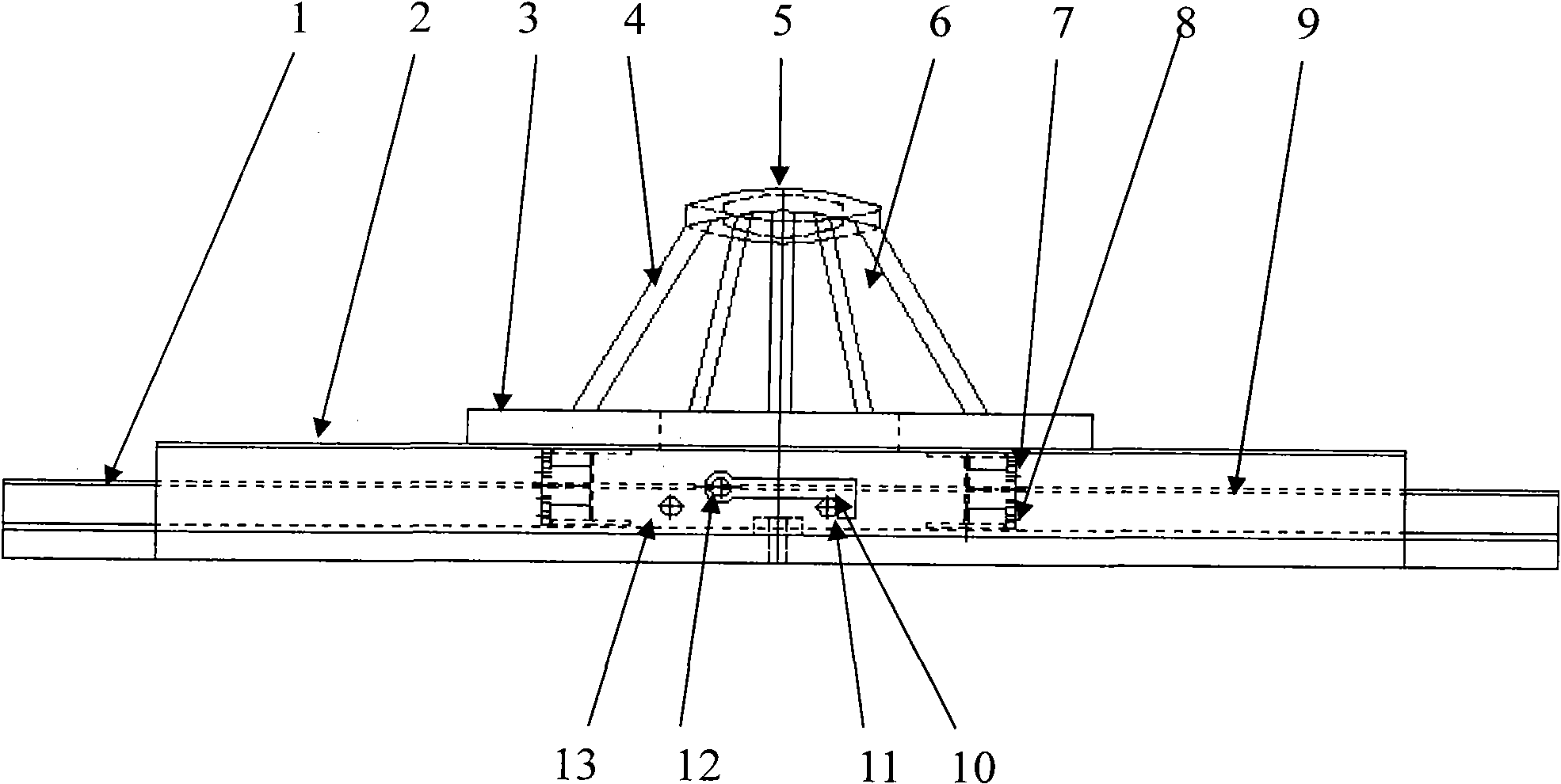

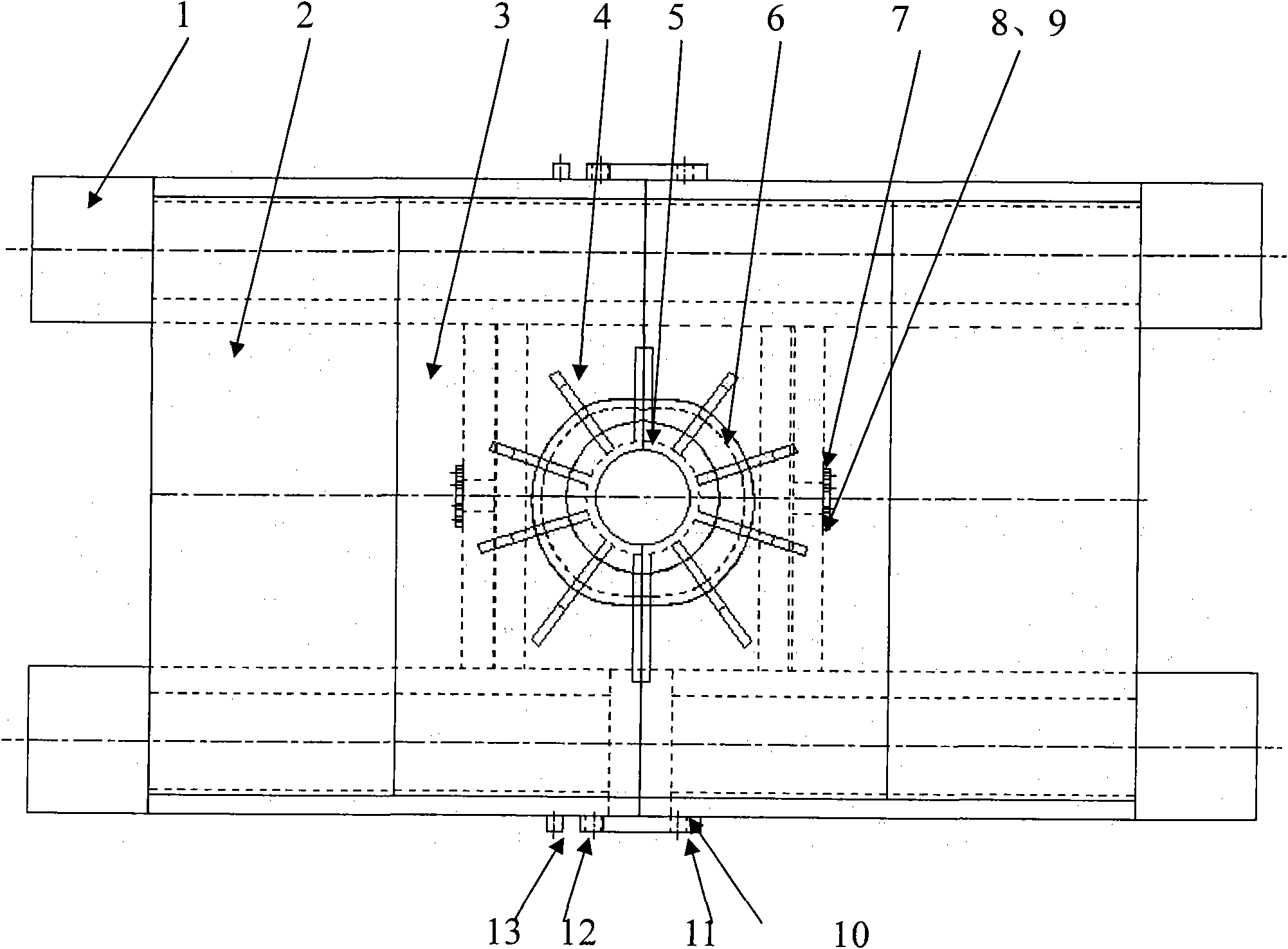

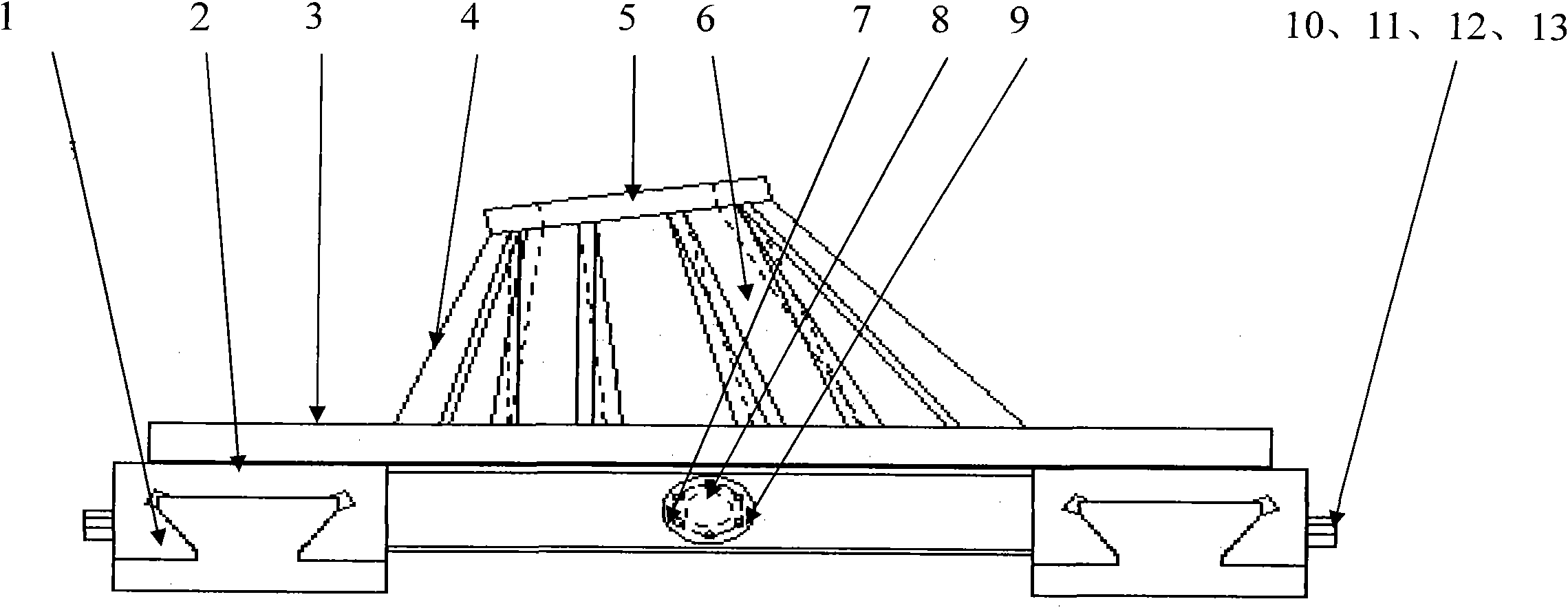

[0026] Such as Figure 1-Figure 4 As shown, the present invention includes: two slide rails 1, the slide rails are in the shape of a dovetail groove, and two corresponding slide plates 2 are installed on the slide rails, the slide plate 2 is a boss structure, and the slide rails are provided with Cooperating dovetail grooves; one end of the two slide plates 2 is respectively installed with a hydraulic cylinder 9 corresponding to each other, and the hydraulic cylinder rod of the hydraulic cylinder 9 is connected with the slide plate 2 as a whole through the flange plate 7 and the bolt and nut pair 8. The other ends of the two slide plates 2 correspond to each other and adopt a welding method to install a conical half-ring cylinder 6. The upper and lower ends of the conical half-ring cylinder 6 are welded to install an upper support plate 5 and a lower support plate 3, and the half-ring cylinder 6 is welded. Has a set inclination angle that applies to the riser catenary form. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com