Method of manufacturing custom plate and strip

A technology of strips and steel strips, which is applied in the field of manufacturing steel strips, can solve problems such as damage and achieve high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

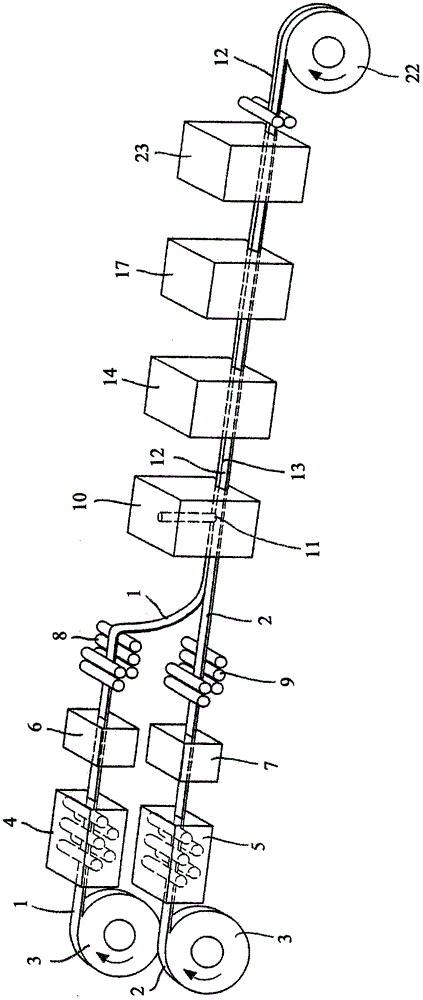

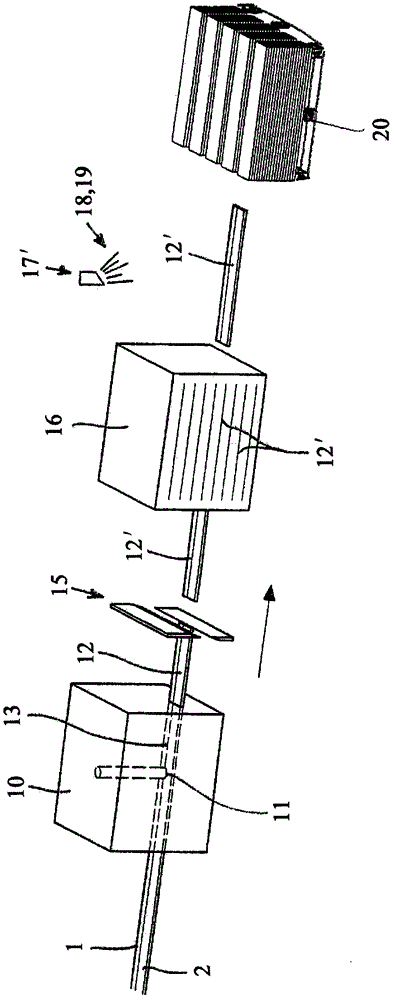

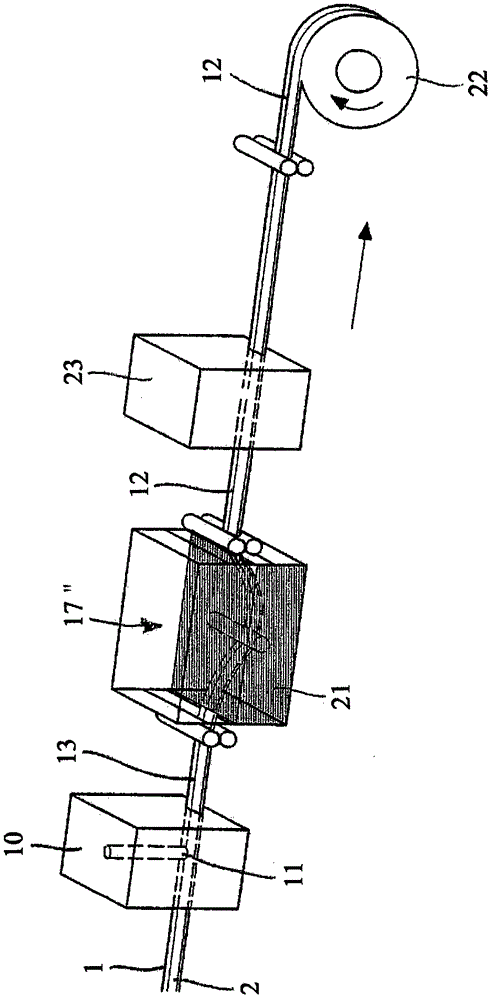

[0022] For the production of tailored strips (ie Tailored Strips), in particular steel strips, two, three or more cut strips 1 , 2 of different materials and / or thicknesses are welded together along their long sides. The cutting strips 1, 2 to be welded to each other are uncoated and exist in the form of a coil 3 (see figure 1 ). Firstly, the individual cut or steel strips 1 , 2 are leveled in separate straightening machines 4 , 5 after being unwound from the respective coil 3 . Next, frame processing takes place, wherein at least the frame to be welded of the cutting strips 1 , 2 can be run through a grinding machine and / or milling machine 6 , 7 in preparation for a subsequent welding process.

[0023] The cutting strips 1, 2 are conveyed to the same welding device 10 by means of separate conveyors (boosting units) and strip conveyors, in particular via strip conveyor wheels, or in the case of more than two cutting strips 1, 2 , sent to the welding device whose number is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com