Double-cutterhead horizontal ultra-precision hydrostatic motorized spindle system

An ultra-precision, double-cutter technology, applied in fine working devices, working accessories, stone processing equipment, etc., can solve the problems of low rigidity and low processing efficiency, and achieve high transmission efficiency, improved processing efficiency, and good dynamic effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

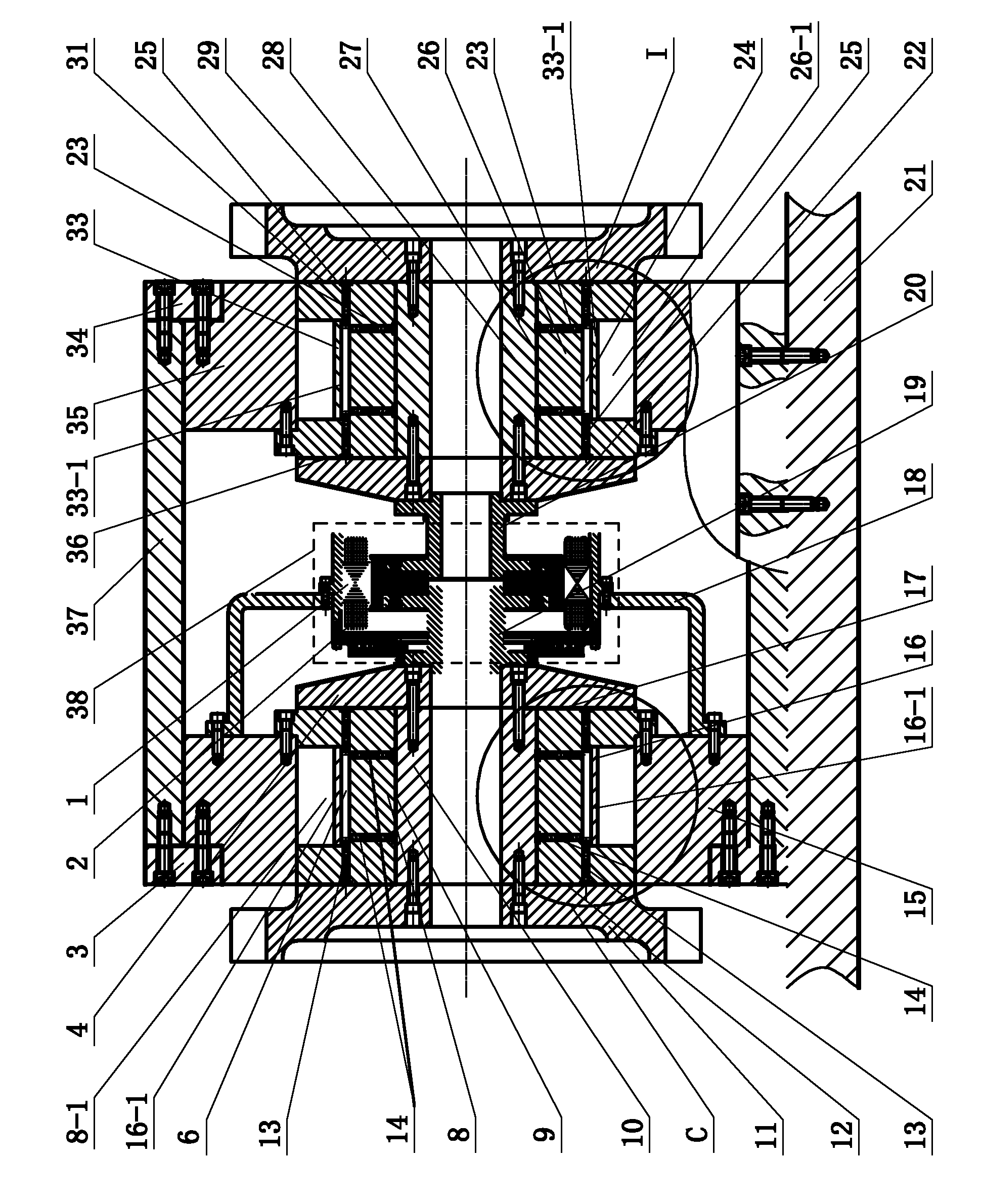

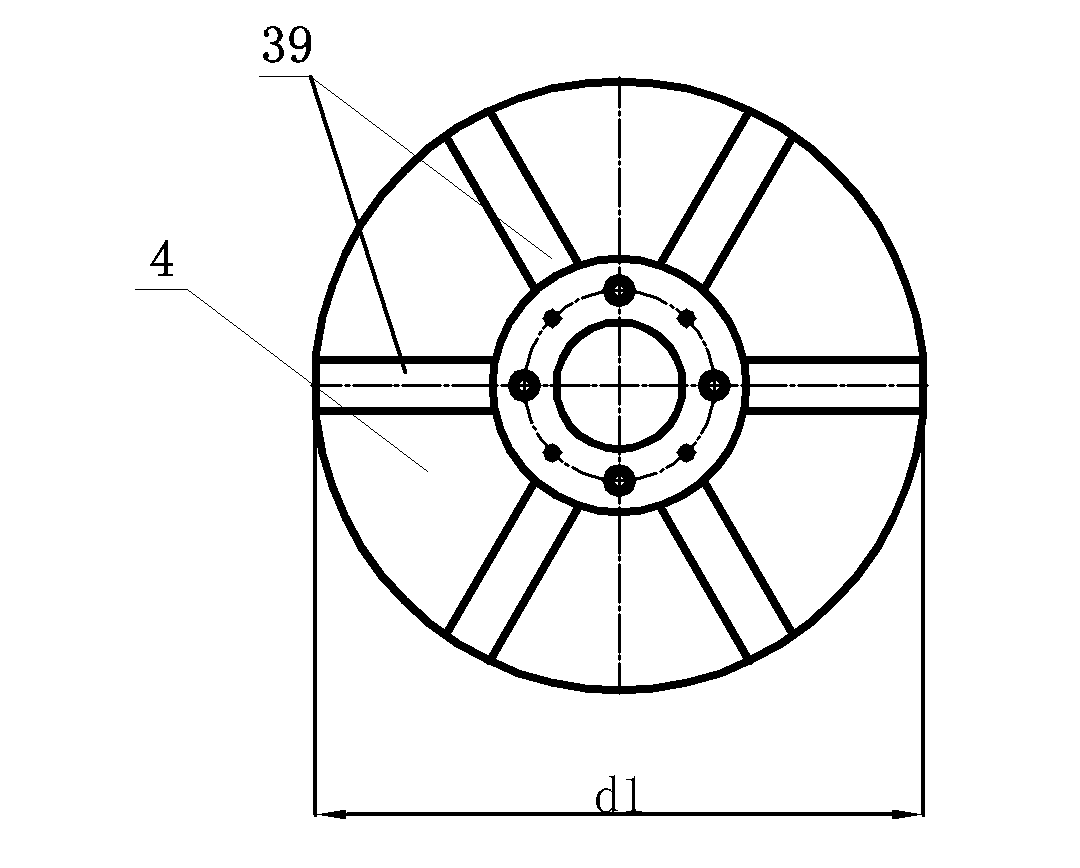

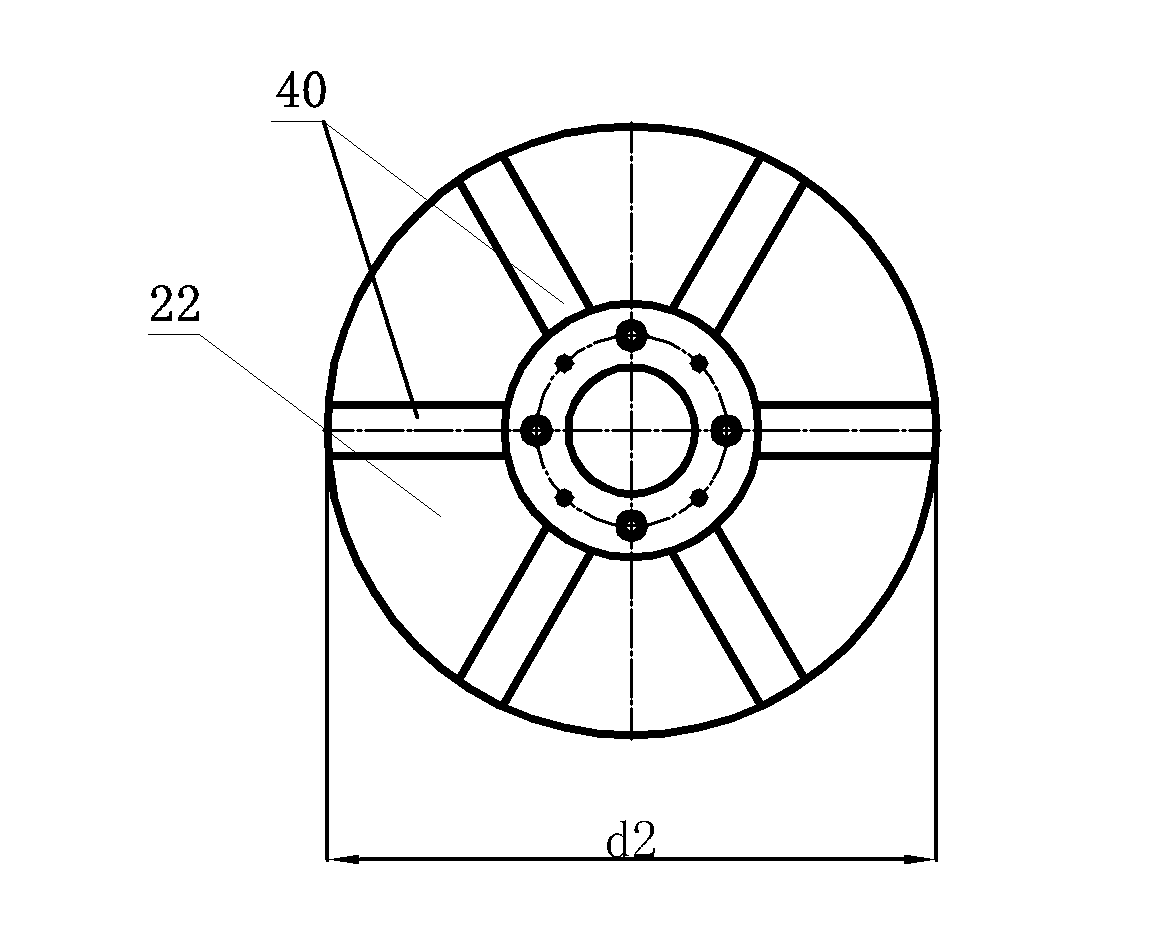

[0010] Specific implementation mode one: as Figure 1-7 As shown, the double cutterhead horizontal ultra-precision hydrostatic electric spindle system of this embodiment includes a first fixed baffle 3, a first spindle 10, a motor bracket 18, a first thrust plate 4, a first cutterhead 11, The first shaft sleeve 8, the first shafting bracket 15, the first oil chamber cover 16, the housing 37 and the DC double output shaft motor 38, the main shaft system also includes the second fixed baffle 34, the second main shaft 28, the first Two thrust plates 22, a second cutter head 29, a second shaft sleeve 26, a second oil chamber cover 33 and a second shafting bracket 35; the first shafting bracket 15 is located at one end of the inner cavity of the casing 37, so that The first shafting bracket 15 is fixedly connected to the housing 37 through the first fixed baffle 3, the second shafting bracket 35 is located at the other end of the inner cavity of the housing 37, and the second shaft...

specific Embodiment approach 2

[0013] Specific implementation mode two: as figure 1 As shown, the DC dual output shaft motor 38 in this embodiment is a DC dual output shaft brushless drive motor. With such a design, the driving effect is good. Other components and connections are the same as those in the first embodiment.

[0014] The DC dual output shaft motor 38 of the present embodiment is composed of a stator 1 and a rotor 2, and the rotor 2 of the DC brushless drive motor system 38 is fixedly connected with the first motor shaft 19 and the second motor shaft 20 at the same time, and the brushless drive motor is used as The driving element, since there is no brush, there is no frictional moment between the stator 1 and the rotor 2 of this motor, and the rotational torque can be directly generated to drive the first main shaft 10 and the second main shaft 28 to rotate simultaneously and perform cutting.

specific Embodiment approach 3

[0015] Specific implementation mode three: as Figure 4 As shown, the ranges of the first gap D, the second gap E, and the third gap F in this embodiment are all 4-6 μm. Such a design effectively improves the rigidity of the hydrostatic oil film and realizes the ultra-precise rotation of the first main shaft 10 . Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com