Molding machine for foam of heat insulation layer of refrigerator

A molding machine and heat insulation layer technology, which is applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve the problems of flammability, high logistics costs, and large space occupation, and overcome the problems of light weight, large space occupation, and Eliminate flammable, cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

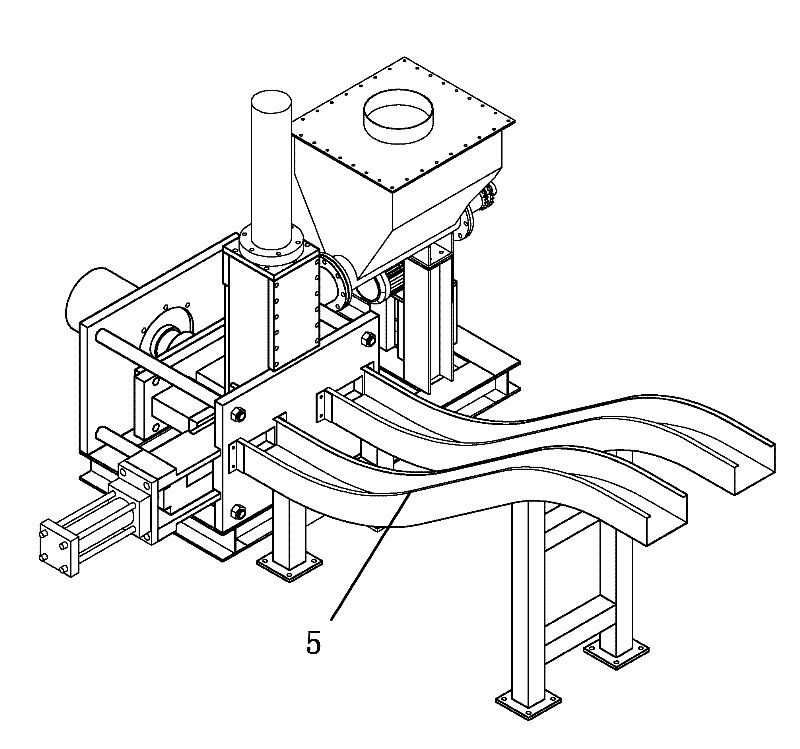

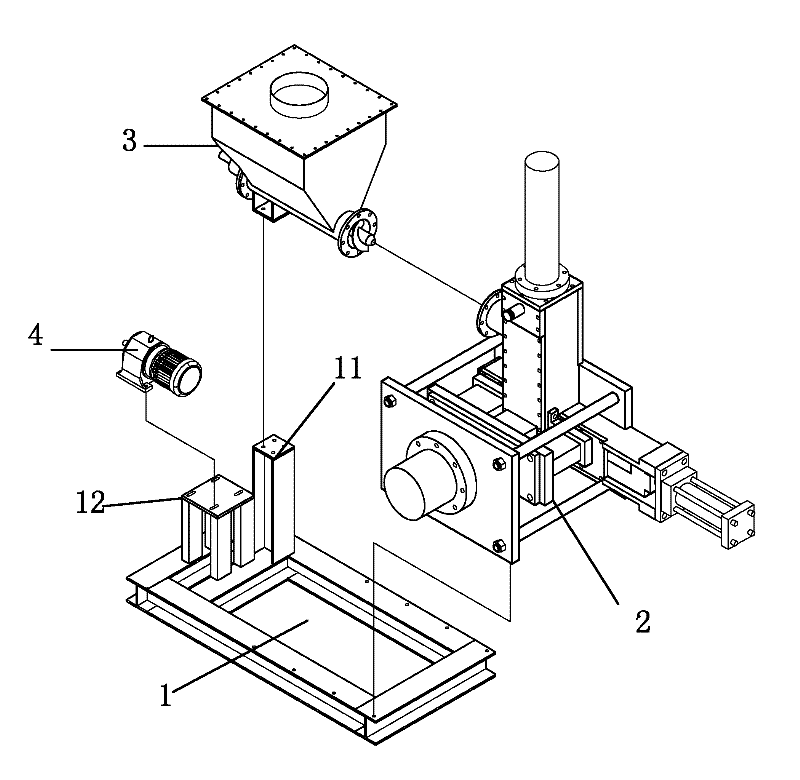

[0028] Such as figure 1 , figure 2 Shown is a schematic view of the overall structure and an exploded view of the waste refrigerator insulation layer foam forming machine of the present invention. A foam forming machine for the heat insulation layer of waste refrigerators, comprising a frame 1, an extrusion molding machine 2, a feeder 3 and a speed reducer 4, the speed reducer, the feeder, and the extrusion molding machine are respectively fixed on the frame, Have the pillar 11 of fixing feeder and the bearing 12 of fixing speed reducer on the stand. The extrusion molding machine is connected to the discharge conveying trough 5 .

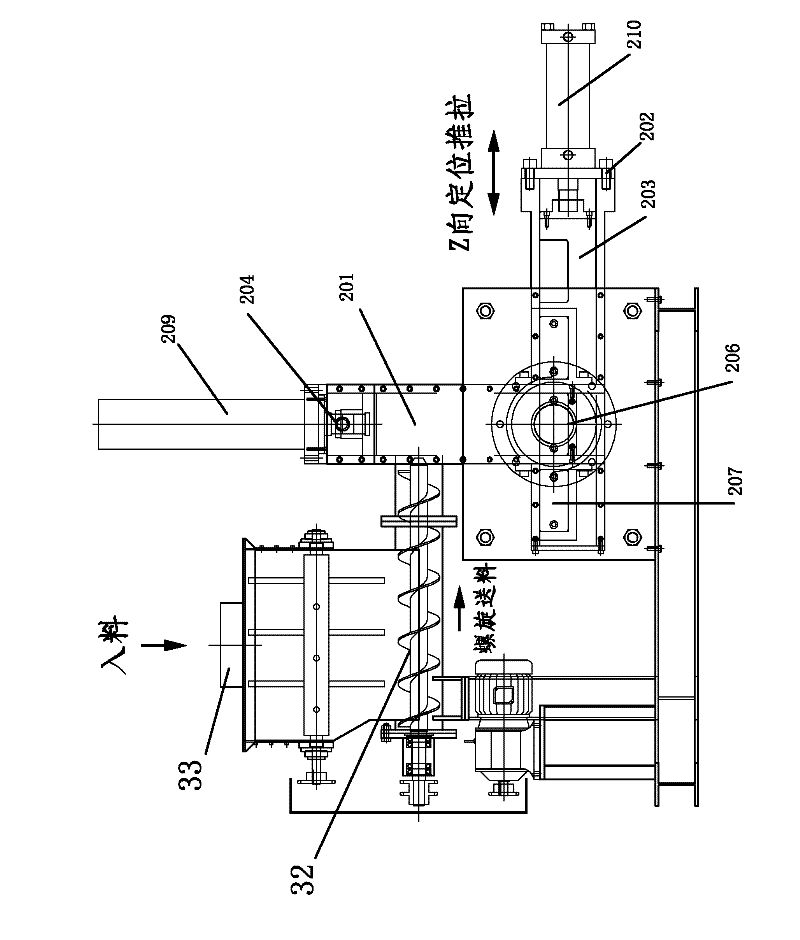

[0029] Such as image 3 , Figure 4 , Figure 5 Shown is a schematic front view, a schematic left view and a schematic right view of the overall structure of the waste refrigerator insulation layer foam molding machine of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com