Method for preparing modified sulfomethal phenolaldehy resin for drilling liquid

A technology of sulfonated phenolic resin and drilling fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor salt resistance performance, achieve good salt resistance performance, increase adsorption capacity, and reduce fluid loss The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing a modified sulfonated phenolic resin for drilling fluid, comprising the following steps:

[0026] a) mixing sodium hydroxide solution, molten phenol, epichlorohydrin and trimethylamine, and reacting to obtain a cationic intermediate;

[0027] b) mixing the cationic intermediate with the sulfonated phenolic resin, and reacting to obtain the modified sulfonated phenolic resin for drilling fluid.

[0028] The present invention uses sodium hydroxide solution, molten phenol, epichlorohydrin and trimethylamine as raw materials to prepare a quaternary ammonium salt cationic intermediate, and then uses the quaternary ammonium salt cationic intermediate as a modifier to modify the sulfonated phenolic resin, A modified sulfonated phenolic resin for drilling fluid is obtained.

[0029] The present invention first uses sodium hydroxide solution, molten phenol, epichlorohydrin and trimethylamine as raw materials to synthesize cationic i...

Embodiment 1

[0051] Adding 30kg of mass concentration to the reactor is 30% sodium hydroxide solution, then slowly adding 63kg of molten phenol, and reacting for 0.5h; continue to slowly add 62kg of epichlorohydrin to the reactor, and the temperature of the reactor during the addition process is not constant. If the temperature exceeds 40°C, after adding the epichlorohydrin, raise the temperature to 60°C and react for 1 hour; cool down to 45°C, and slowly add 120kg of trimethylamine into the reaction kettle. After completion, react at 60°C for 30 minutes to obtain a cationic intermediate;

[0052] Add 175kg of formaldehyde and 30kg of water into the reactor, then add 100kg of molten phenol, and stir evenly; slowly add 38kg of sodium pyrosulfite solid to the reactor, and react for 15 minutes after sodium pyrosulfite dissolves; slowly add 63kg of sodium pyrosulfite into the reactor Sodium sulfate water, stirred and reacted at 60°C for 30min; then heated to 100°C for 3h, added 60kg of the cat...

Embodiment 2

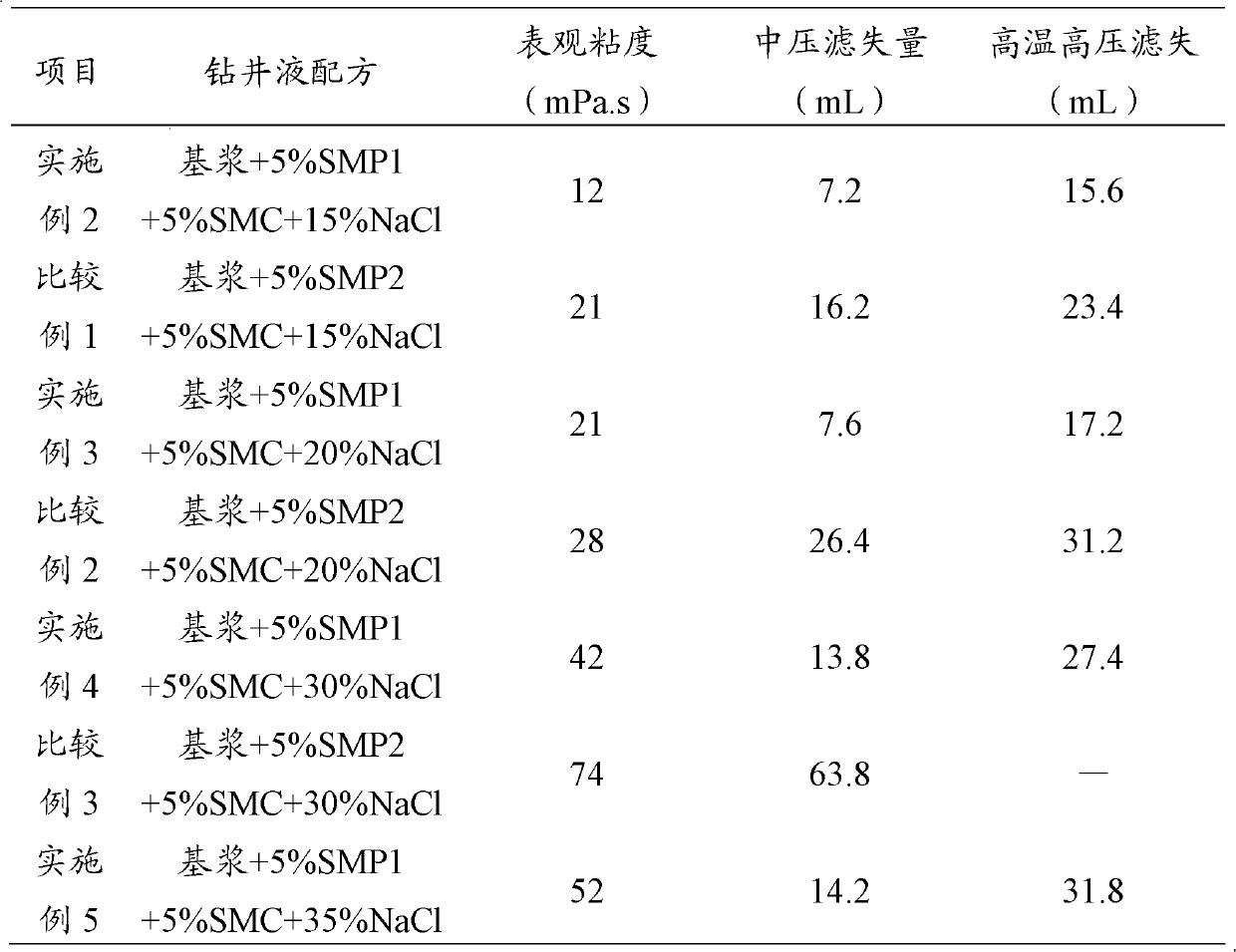

[0054] Add 60g sodium bentonite and 5.0g anhydrous sodium carbonate in 1000mL water and be mixed with base slurry, add the modified sulfonated phenolic resin of 50g embodiment 1 preparation, 50g sulfonated lignite (SMC) and 150gNaCl in described base slurry, obtain Drilling fluid, according to the method specified in "SY / T5094-2008 Drilling Fluid Sulfomethyl Phenolic Resin", the performance test of the drilling fluid is carried out, the results are shown in Table 1, and Table 1 is the drilling provided by the embodiments of the present invention and comparative examples Liquid performance test results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com