Preparation method of coupling phenolic resin used for drilling fluid

A technology of phenolic resin and drilling fluid, which is applied in the direction of drilling compositions, chemical instruments and methods, and can solve problems such as low salt resistance, unstable fluid loss resistance to high temperature and high pressure, and low temperature resistance of fluid loss reducers. , to achieve the effect of improving the bonding effect and improving the filter reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

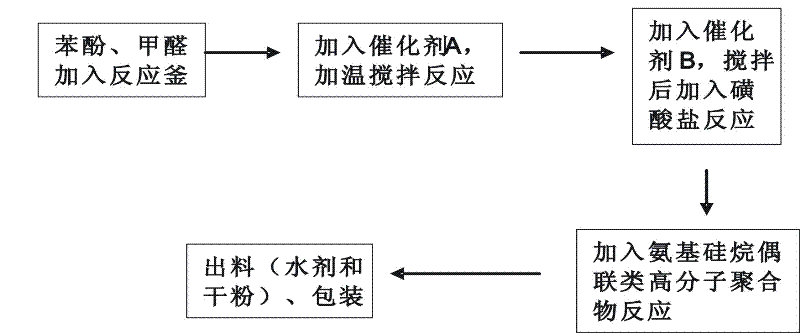

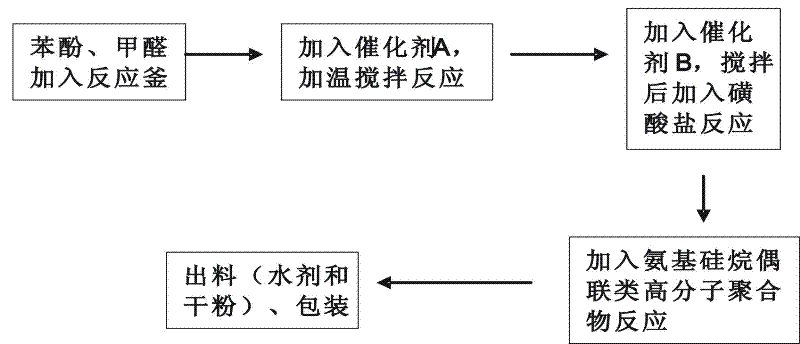

[0018] according to figure 1 According to the process flow, 100 parts of phenol and 130 parts of formaldehyde are sequentially added to the reaction kettle with a stirrer in the reflux cooler according to the mass ratio, and under the action of 2 parts of hydrochloric acid, heat at 100°C and stir for 45 minutes. Then add 15 parts of sodium hydroxide and 170 parts of sodium metabisulfite and heat at 100°C for 1.5 hours, then add 75 parts of N-2-(aminoethyl)-3-aminopropyltrimethoxysilane and then heat at 100°C to continue After 3 hours of reaction, the material is discharged to obtain a coupled phenolic resin, which is then made into water or powder for packaging.

Embodiment 2

[0020] according to figure 1 According to the mass ratio, 100 parts of phenol and 130 parts of formaldehyde are sequentially added to the reaction kettle with a reflux cooler with a stirrer, and under the action of 2 parts of p-toluenesulfonic acid, heat at 95°C and stir the reaction 50 minutes, then add 15 parts of sodium hydroxide and 170 parts of sodium metabisulfite and heat at 90°C for 2 hours, then add 75 parts of N-(βaminoethyl)-γ-aminopropylmethyl-dimethoxysilane Reheat at 100°C and continue to react for 3 hours, then discharge the material to obtain the coupled phenolic resin, which is then made into water or powder for packaging.

Embodiment 3

[0022] according to figure 1 According to the mass ratio, 100 parts of phenol and 130 parts of formaldehyde are sequentially added to the reaction kettle with a reflux cooler with a stirrer, and under the action of 2 parts of oxalic acid, heat at 100°C and stir for 35 minutes. Then add 15 parts of sodium hydroxide and 170 parts of sodium metabisulfite and heat at 105°C for 2 hours to react, then add 75 parts of 3-aminopropyltriethoxysilane and heat at 105°C to continue the reaction for 3 hours, then discharge. The coupled phenolic resin is obtained, and then made into water or powder for packaging.

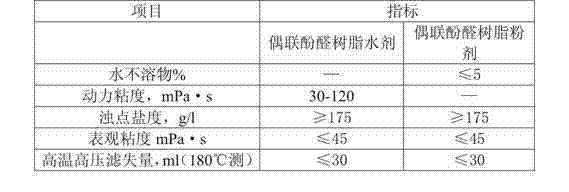

[0023] Measured according to the standard method, the coupling phenolic resin obtained in the above examples was made into the corresponding water and powder respectively and compared with the sulfomethyl phenolic resin (SMP) type II water powder for index comparison. The comparison of the measured index parameters is shown in Table 2:

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com