Spiral pile drilling machine

A technology of helical ground piles and drilling rigs is applied in the directions of rotary drilling rigs, rotary drilling, sheet pile walls, etc. The effect of advanced precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

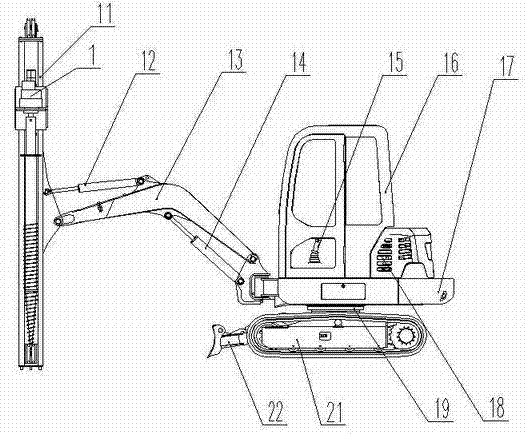

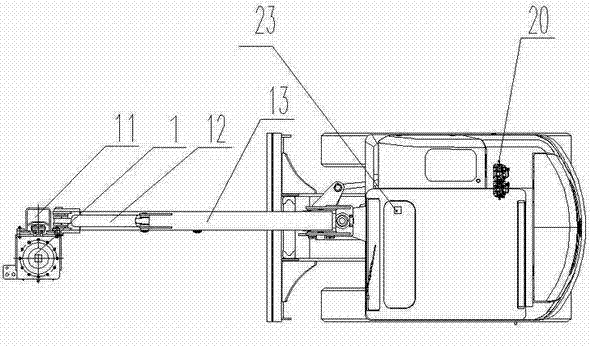

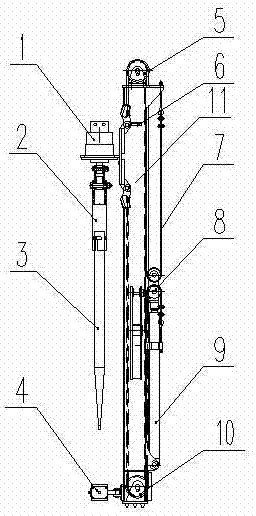

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] exist Figure 1 to Figure 3 The shown helical pile drilling rig includes a traveling chassis 21, a platform rotating mechanism 19 driven by a hydraulic motor on the traveling chassis 21, a platform 17 on the platform rotating mechanism 19, a power system 18 on the platform 17, a hydraulic system 20 and driver's cab 16, boom 13, boom lifting cylinder 14, screw ground pile driving coupling device, and pitching cylinder 12, the power system 18 and hydraulic system 20 are located at one end of platform 17, and one end of boom 13 is hinged At the end of the platform 17 away from the power system 18 and the hydraulic system 20, the two ends of the boom lifting cylinder 14 are respectively hinged with the boom 13 and the platform 17, and the screw ground pile drive coupling device is hinged with the other end of the boom 13, and the pitch The two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com