Ammonia supply device, ammonia supply method and exhaust gas purification system

A waste gas purification system and equipment technology, applied in the direction of mechanical equipment, separation methods, chemical instruments and methods, etc., can solve problems such as unevenness, increased power consumption, and low-efficiency release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

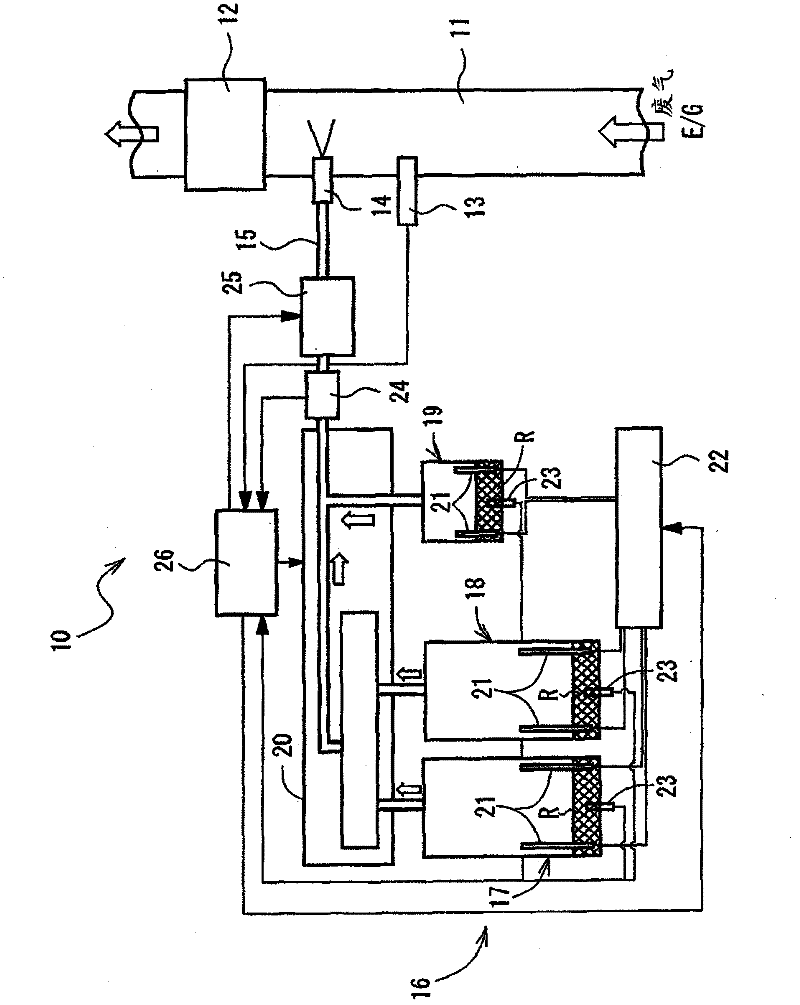

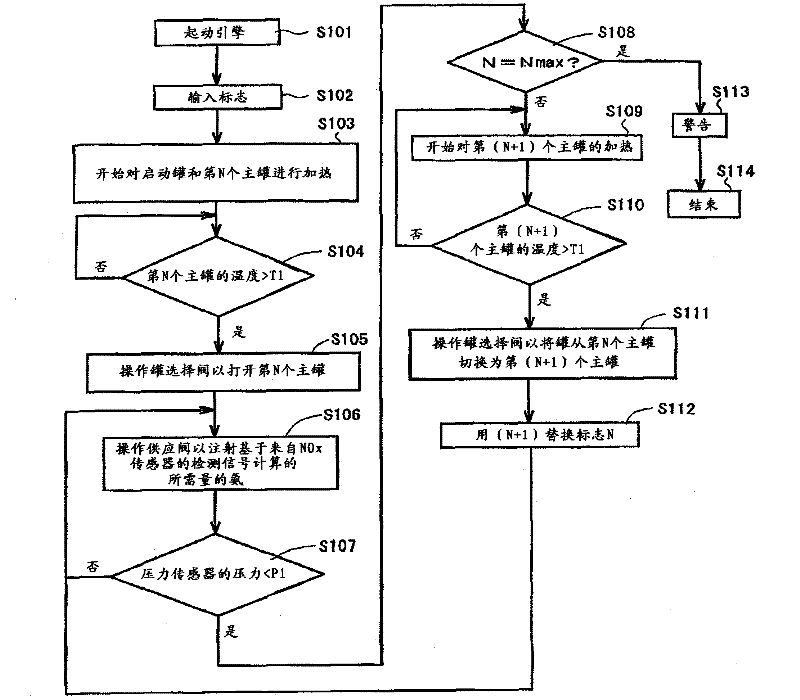

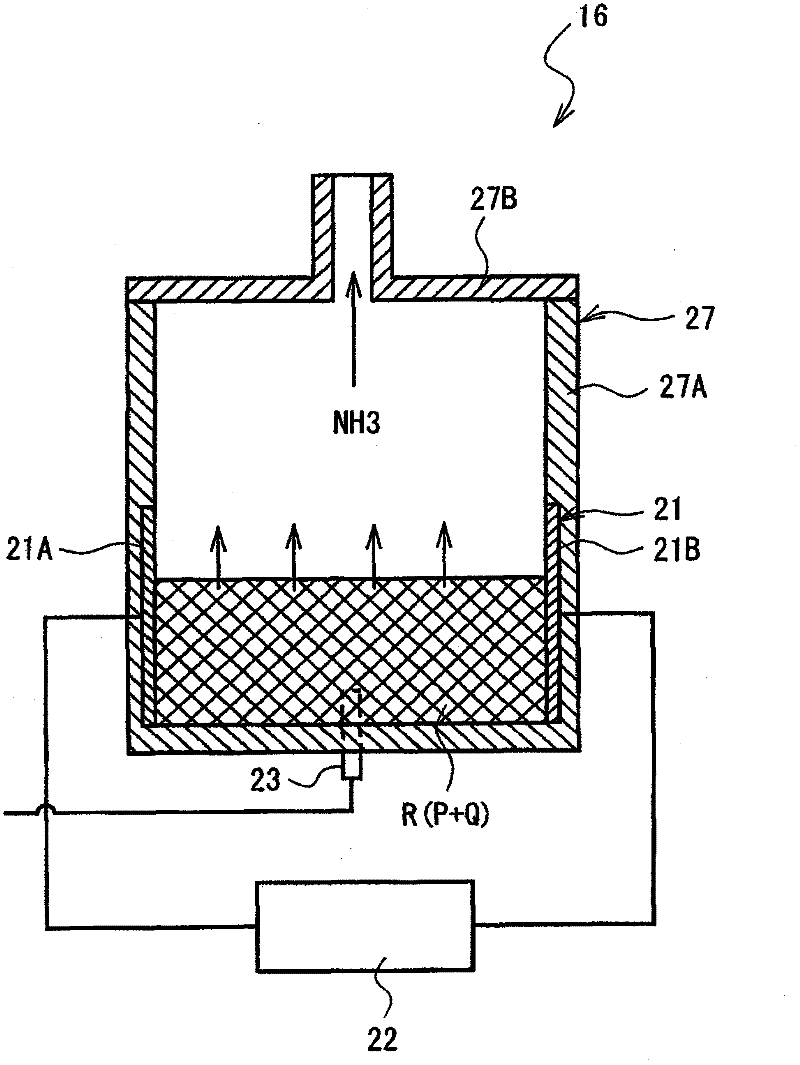

[0017] Below, refer to figure 1 Turning to FIG. 4, the exhaust gas purification system according to the first preferred embodiment of the present invention is described. Such as figure 1 As shown, an exhaust gas purification system generally indicated by reference numeral 10 serves to remove harmful substances such as nitrogen oxides (NOx) contained in exhaust gas discharged from a diesel engine (not shown) as an internal combustion engine, the exhaust gas The purification system is arranged in the exhaust gas passage 11 through which the exhaust gas passes. A selective catalytic reduction (SCR) catalyst 12 for providing selective reduction of NOx contained in exhaust gas is also arranged in the exhaust gas passage 11 . The SCR catalyst 12 is made of something such as iron zeolite that has ammonia absorption with relatively high NOx catalytic conversion efficiency at a relatively low temperature.

[0018] A nitrogen oxide sensor (NOx sensor) 13 is arranged in the exhaust pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com