Static mixer of selective catalytic reduction (SCR) denitration system

A static mixer and denitrification technology, applied in the direction of machines/engines, chemical instruments and methods, separation methods, etc., can solve problems such as unsatisfactory conversion rate and ammonia escape rate, poor disturbance effect, uneven concentration distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of the patent of the present invention, such as: the shape and structure of each structure, the mutual positional relationship and connection relationship between each part, the role and working principle of each part, etc. Further detailed instructions:

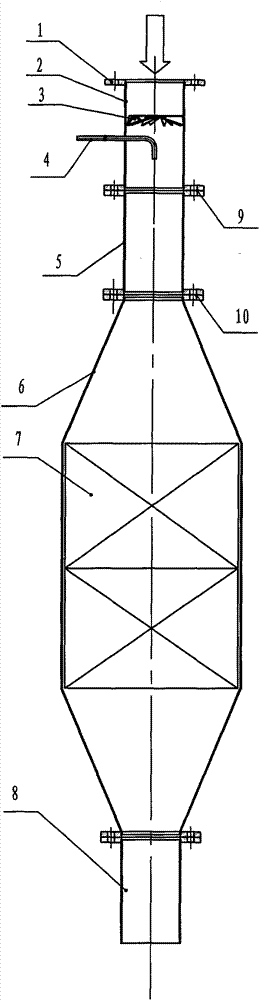

[0016] The patent of the invention is a static mixer of SCR denitrification system, which uses exhaust gas and urea to get fully disturbed and mixed after passing through the mixer. NOx content.

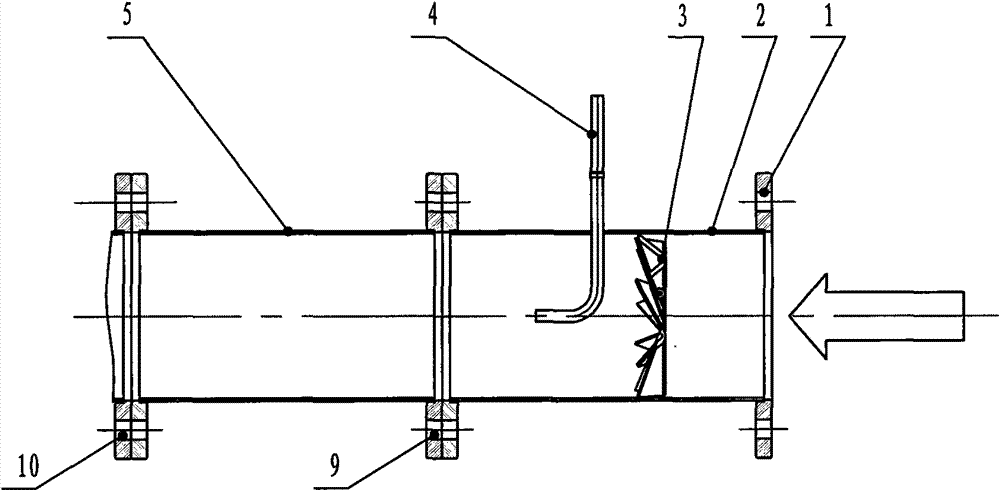

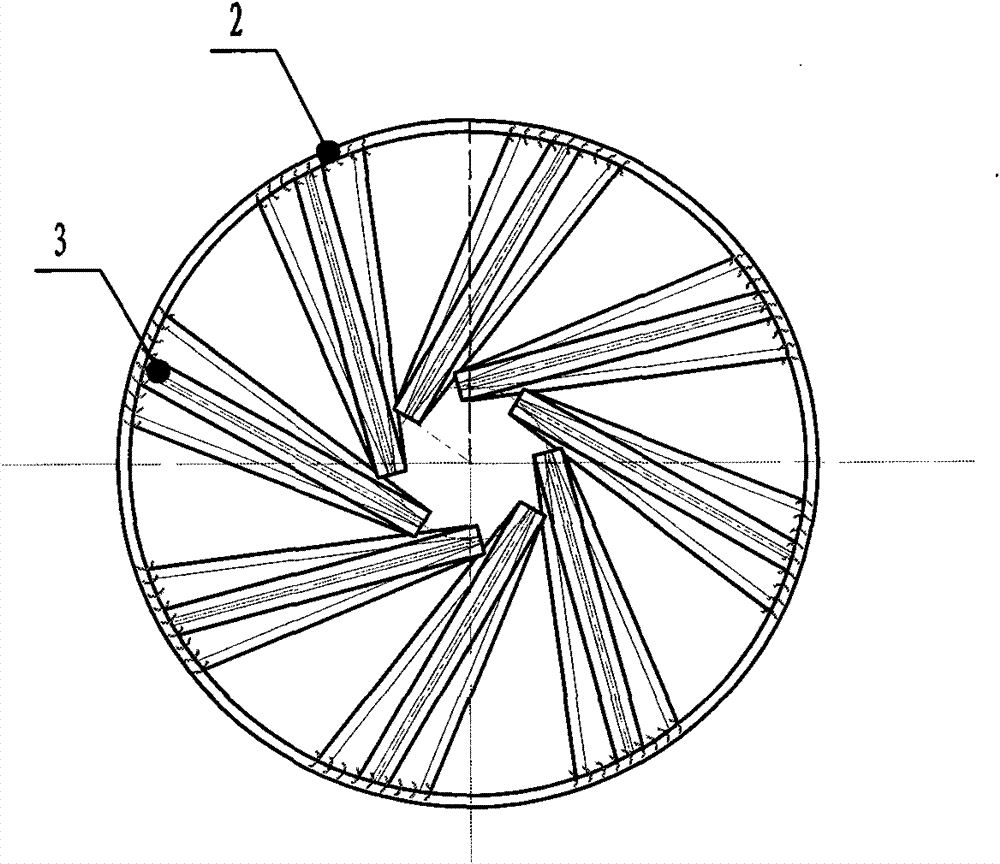

[0017] as attached figure 2 Said, the static mixer of the SCR denitrification system of the present invention, the static mixer of the SCR denitrification system comprises a pipe body 2, fins 3 and nozzles 4, the nozzles 4 are arranged on the pipe body 2, and the fins The section of the piece 3 is "V" shaped, and a plurality of fins 3 are arranged eccentrically in the tube body 2 .

[0018] The two ends of the pipe body 2 are respectively connected with the exhaust pipe and the rear end pipe 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com