Lamp radiator structure

A technology of structure and lamps, which is applied to cooling/heating devices of lighting devices, lighting and heating equipment, parts of lighting devices, etc. It can solve the problems of different diameters, increased resistance, waste of cold air, etc., and achieve heat load Uniform distribution, reduced airflow resistance, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

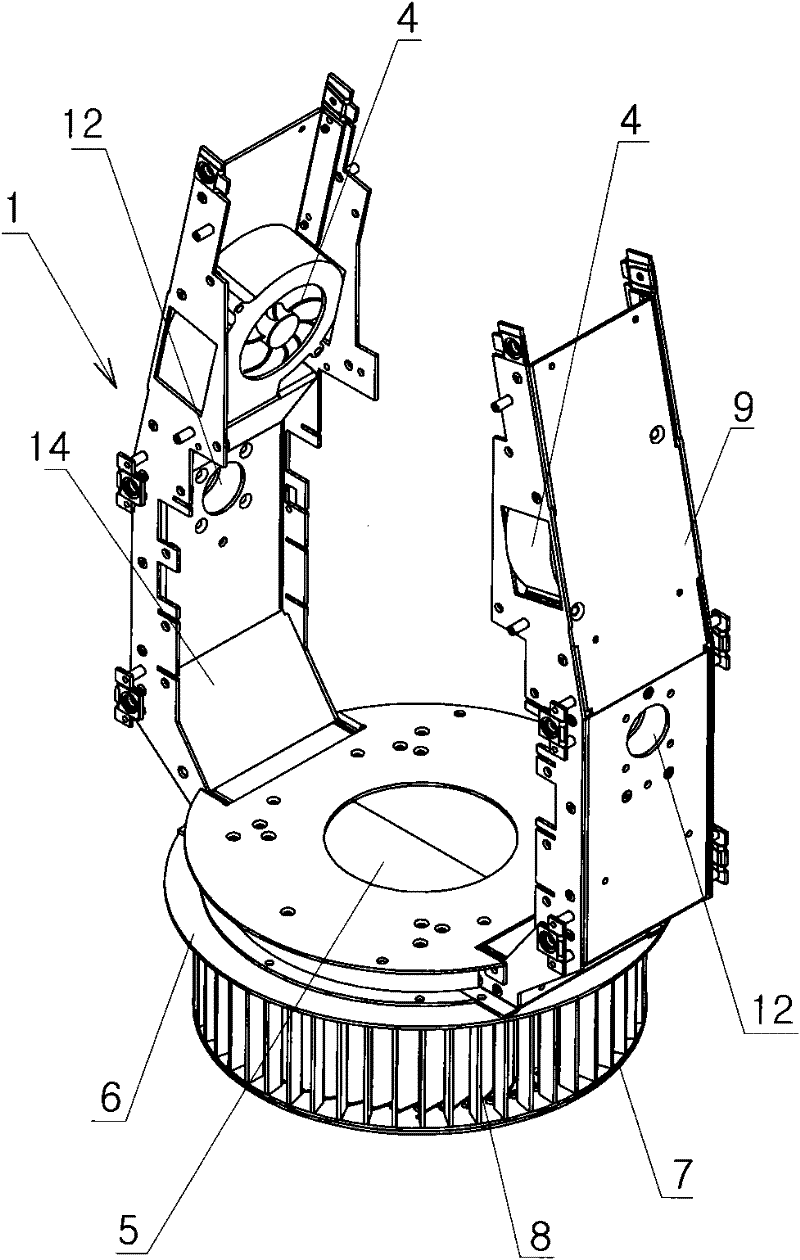

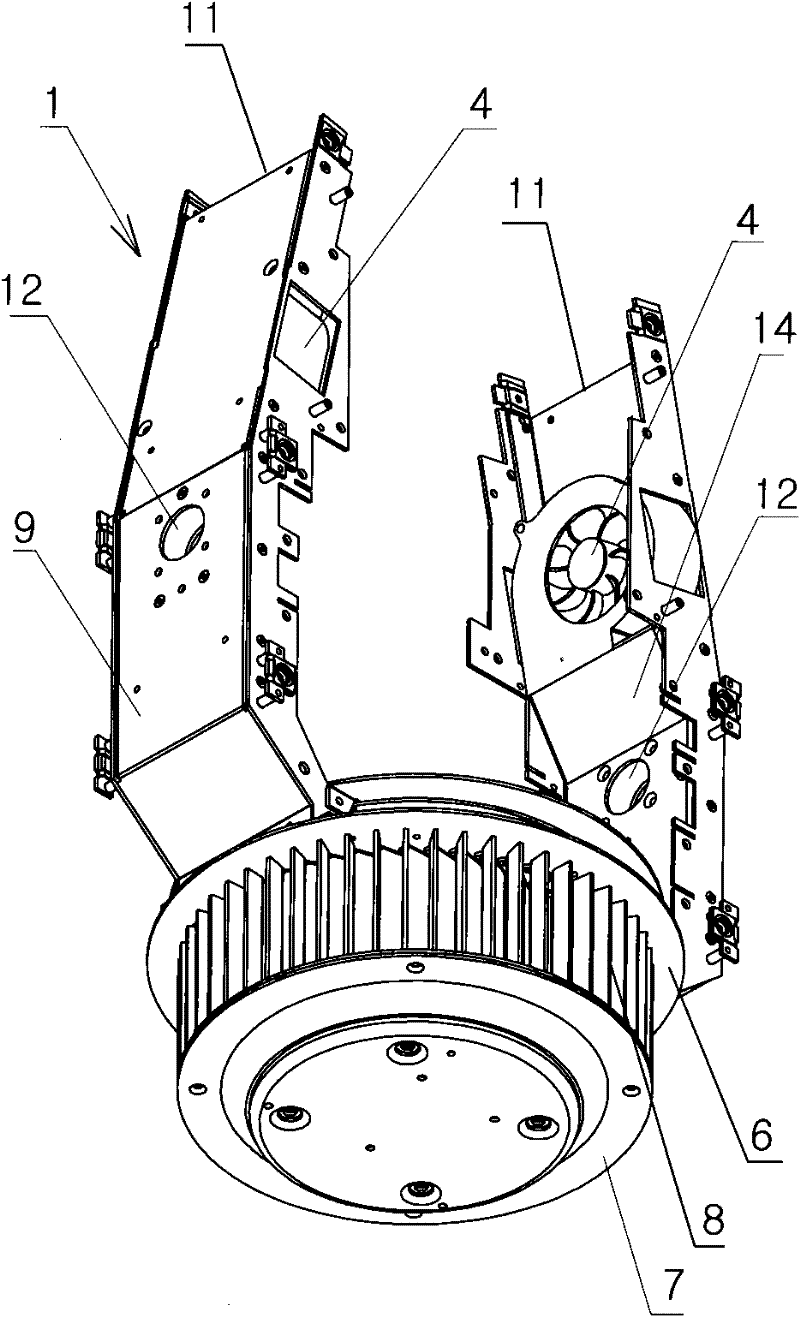

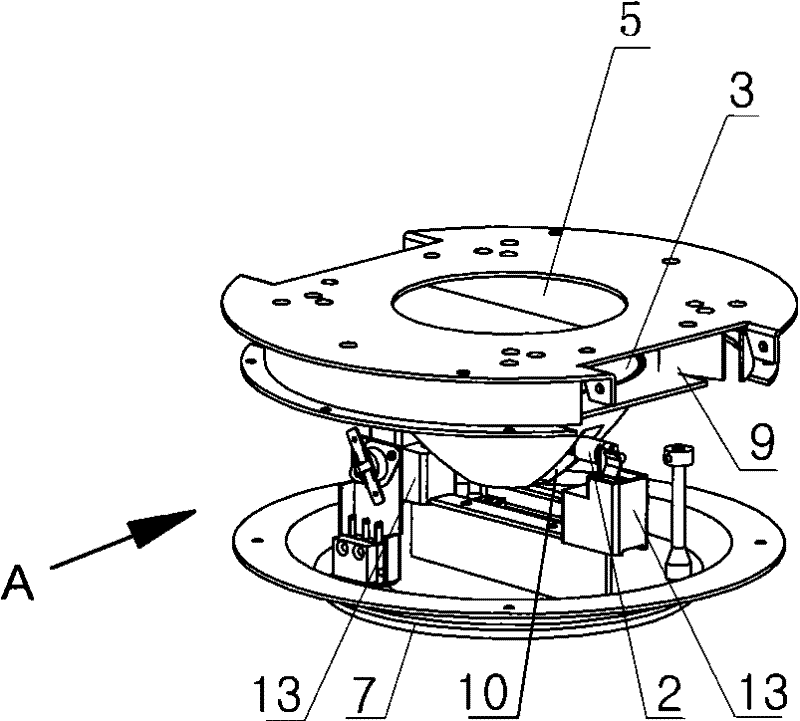

[0021] see Figure 1 to Figure 4 , this embodiment is a moving head light, which has a main body frame 1 made of metal plates, the left and right arms 11 of the main body frame 1 are used to install modules such as focusing, dimming, and color mixing. The base (not shown) is hinged, and the housing (not shown) of the lamp is also mounted on the two arms.

[0022] The radiator is connected below the main frame 1; the radiator is cage-shaped and consists of an upper ring 6, a chassis 7 and fifty fins 8, and one end of each fin 8 along its axis is fixed on the upper ring 6, The other end of each fin 8 along its axis is fixed on the chassis 7, and fifty fins 8 are evenly distributed and installed upright along the upper ring 6 and the circumference of the chassis 7, with air gaps between adjacent fins 8 . The fins 8 can be arc-shaped or straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com