Surface shape detection device for solar condensing mirror

A technology of solar concentrating and detecting device, which is applied in the field of mirror surface detection, can solve the problems of inconsistency between the actual surface shape of the condenser mirror and the designed surface shape, affecting the optical performance of the condenser mirror, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

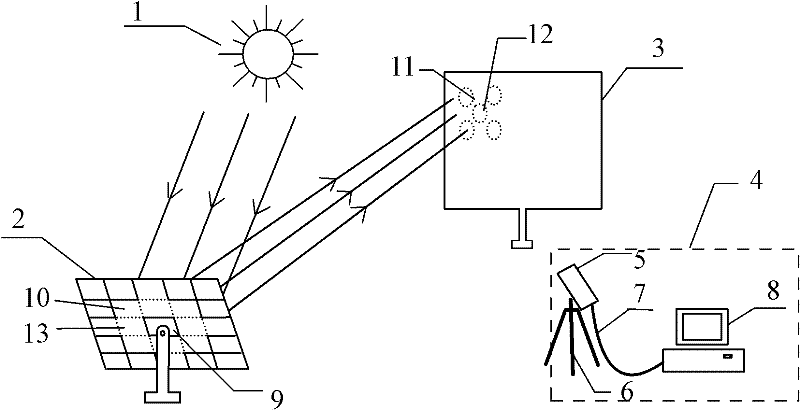

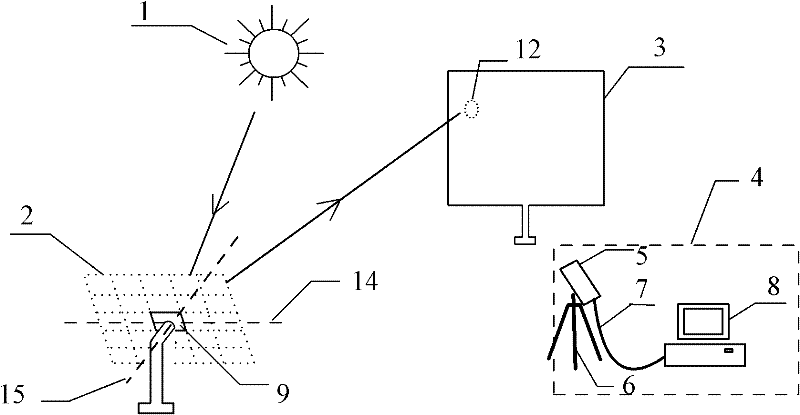

[0022] Such as figure 1 As shown, the light source is the sun 1. Described measured condenser 2 has two rotation axes, rotating shaft one 14 and rotating shaft two 15 perpendicular intersects, and rotating shaft one 14 is parallel to the mirror surface, and the elevation angle of the axis direction of rotating shaft two 15 relative to the horizontal plane can be arbitrarily selected. Condenser 2 can rotate around two axes to track the sun and reflect sunlight to a fixed direction. Condenser 2 is spliced by multi-faceted small reflectors. The light emitted by the sun is projected onto the measured condenser 2 and reflected to the receiving screen 3 by a small reflector. The receiving screen 3 is a plane coated with a diffuse reflection material or a plane with a certain light transmittance, the size of the receiving screen 3 is determined according to the size of the measured condenser lens 2, the position and inclination angle of the receiving screen 3 are adjustable, and c...

Embodiment 2

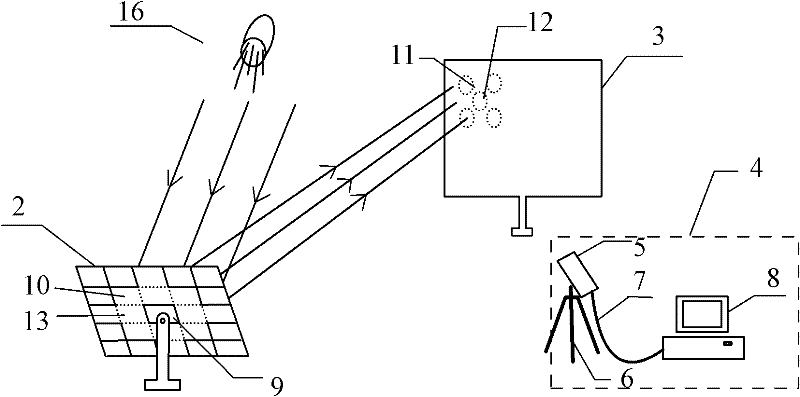

[0024] Depend on image 3 As shown, the solar concentrating mirror surface shape detection device of the present invention includes a light source, a receiving screen and an image acquisition and processing unit. Different from Embodiment 1, the light source is an artificial light source such as a solar simulator 16 capable of producing similar sunlight, such as image 3 As shown, since the position of the solar simulator 16 can be fixed, the condenser 2 can be fixed during the detection and adjustment process of the condenser 2, that is, no tracking operation is required.

Embodiment 3

[0026] Depend on Figure 4As shown, the solar concentrating mirror surface shape detection device of the present invention includes a light source, a plane mirror, a receiving screen and an image acquisition and processing unit. Different from Embodiment 1, the light source is a plane reflector 17 capable of tracking the sun and reflecting sunlight to the detected concentrating mirror surface, such as Figure 4 As shown, since the direction of the light reflected by the plane reflector 17 can be fixed, the condenser 2 can be fixed during the detection and assembly process of the condenser 2, that is, no tracking operation is required.

[0027] The surface shape detection device of the solar concentrating mirror of the present invention realizes the surface shape detection of the large solar concentrating mirror, which is beneficial to improving the optical performance and assembly efficiency of the concentrating mirror. It can detect the solar concentrating mirrors with any s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com