Lithium ion battery

A lithium ion battery, lithium ion technology, applied in the field of its structure, can solve the problems of electrode composite material bending curvature limitation, incomplete mechanical properties, easy separation, etc., to improve electrical conductivity, mechanical reliability, and anti-leakage effect. Significant, improved binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

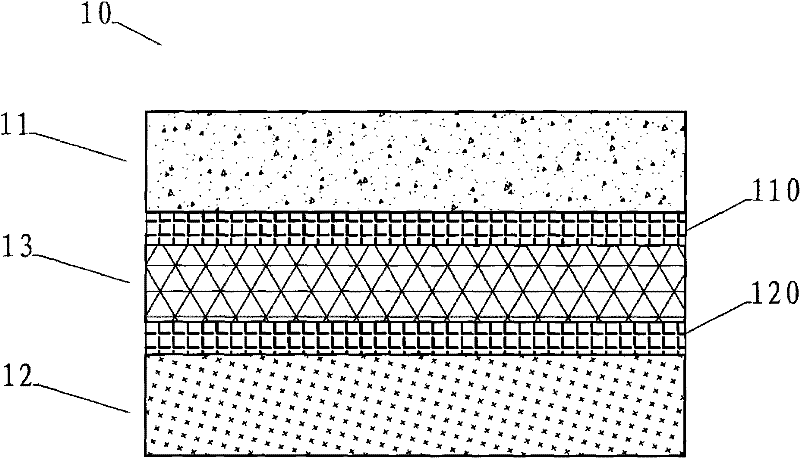

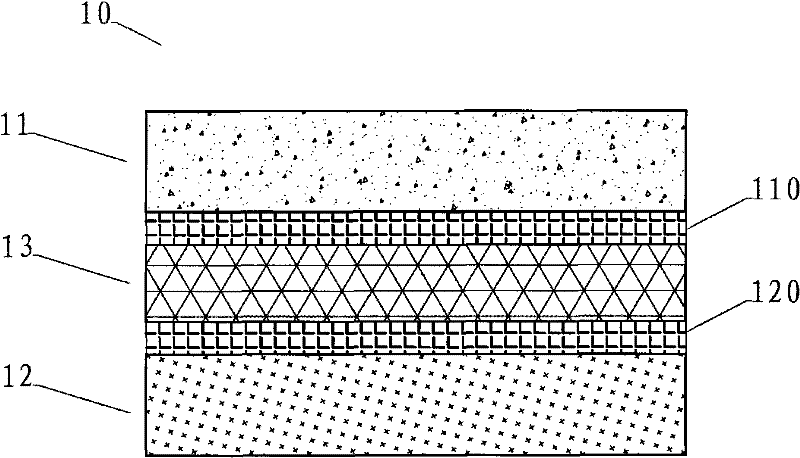

[0010] The present invention provides a lithium ion battery having a casing (not shown) in which: at least one set of a positive electrode layer and a negative electrode layer; a separator layer forming a connection between the positive electrode layer and the negative electrode layer; electrolysis Liquid, the electrolyte LiClO 4 The concentration is 1.5 mol / L, and the volume ratio of solvent propylene carbonate to ethylene glycol dimethyl ether is 8:1; the positive electrode layer or the negative electrode layer at least has a porous permeable layer between the separator layer.

[0011] Such as figure 1 As shown, the present invention provides a lithium ion battery 10, which includes at least one set of a positive electrode layer 11 and a negative electrode layer 12, the positive electrode layer and the negative electrode layer are connected by a separator layer 13, and the carbonized medium substantially wraps the electrode Material and the metal foam, and provide an electrical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com