Bolt clipper with replaceable cutting edge

A technology of bolt cutters and cutting edges, applied in the field of bolt cutters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below through specific examples.

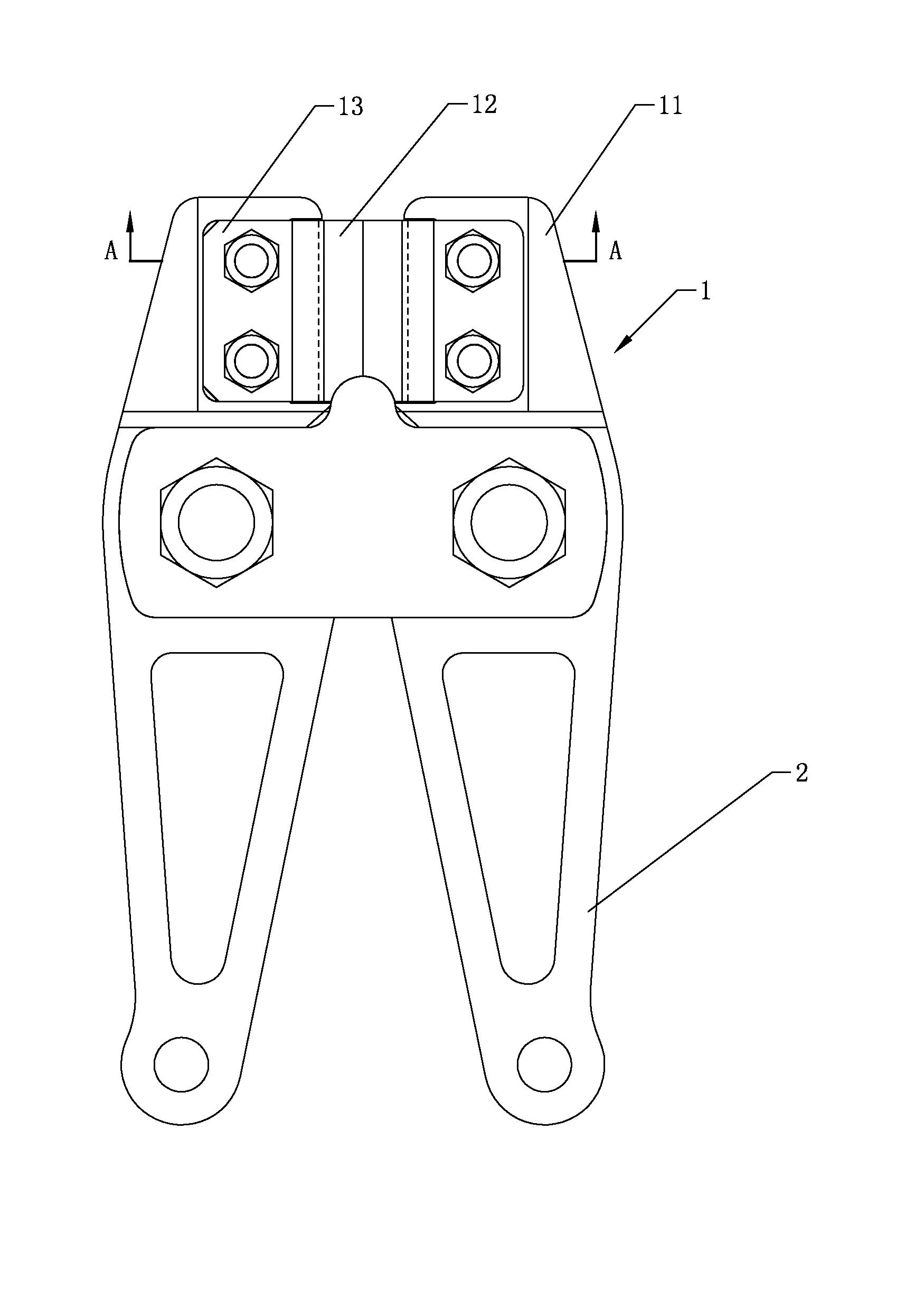

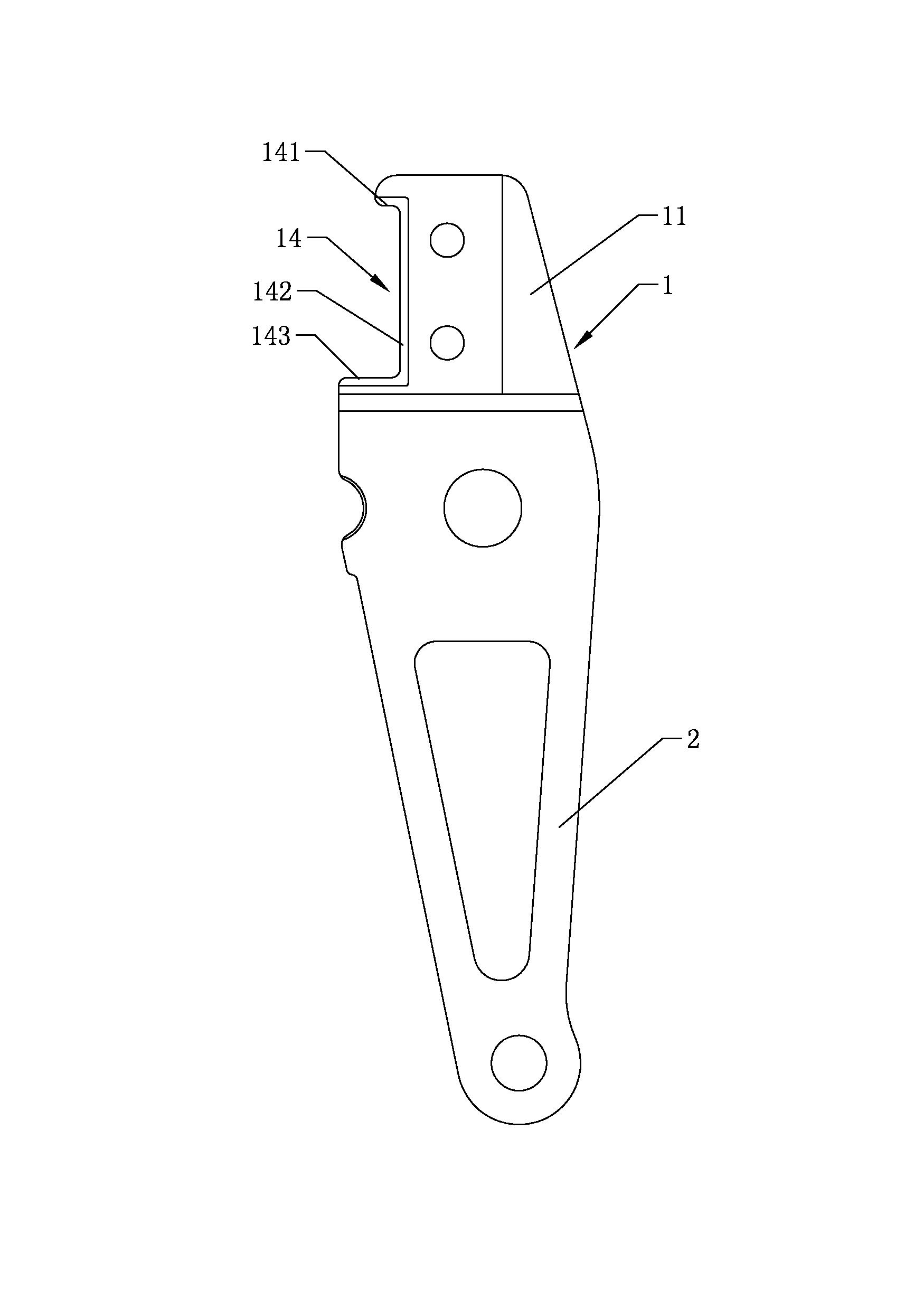

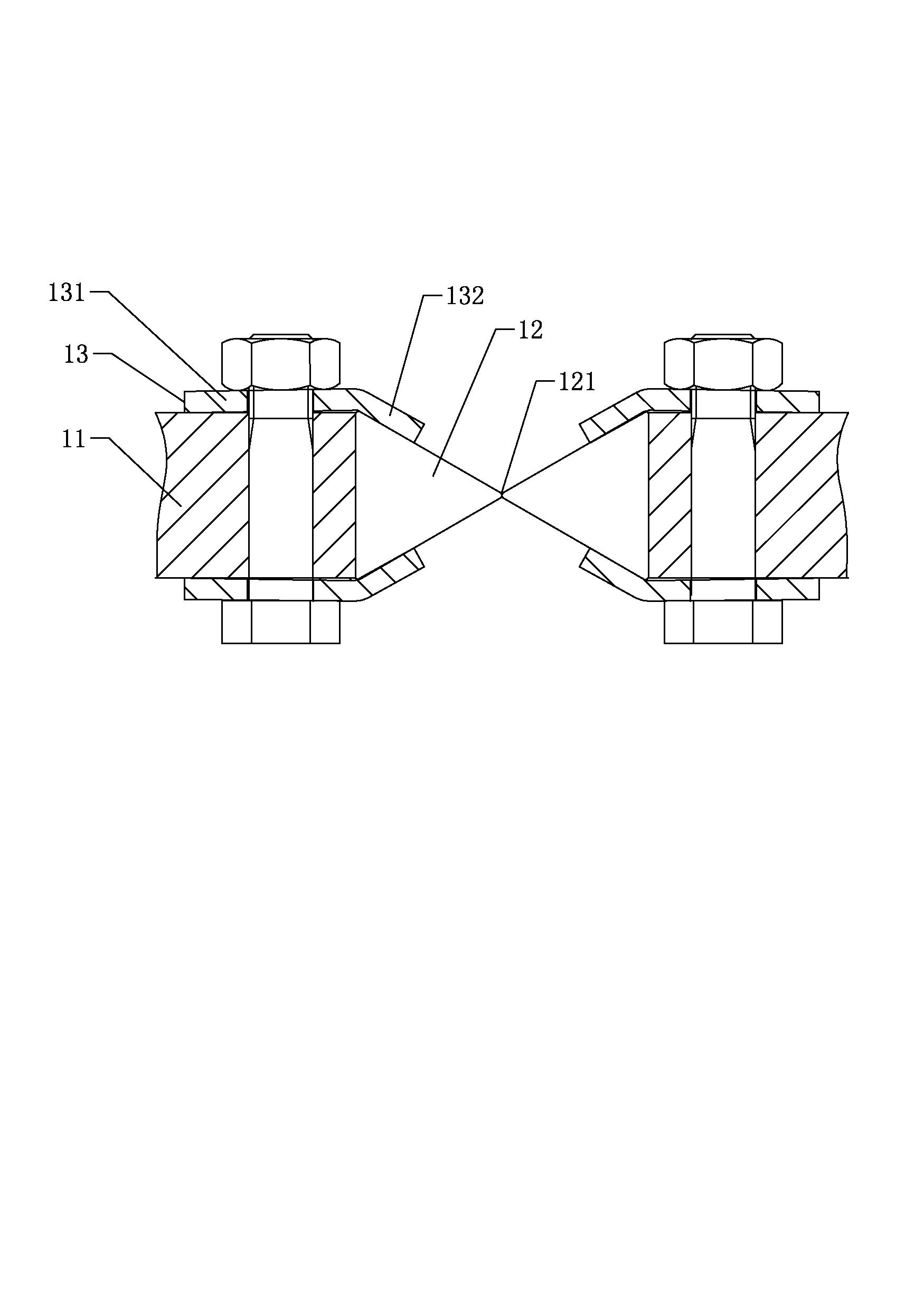

[0015] A type of bolt cutter with replaceable blades, such as figure 1 , figure 2 and image 3 As shown, it includes a cutter head 1 and two pliers handles 2. The cutter head 1 is a split structure, including two cutter head bodies 11 and two blades 12, and each cutter head body 11 is correspondingly arranged At the head of a pliers handle 2, each of the blades 12 is in the shape of a regular triangular prism, at least two edges of the regular triangular prism are set as cutting edges 121, and a cutting edge 121 is collapsed. Replace the installation surface of blade 12, make another cutting edge 121 of blade 12 as working edge, like this, one blade 12 has more than one cutting edge 121 and just prolongs the service life of doubling. Therefore, in the present invention, the three edges of the regular triangular prism are all set as the cutting edges 121, so that the two bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com