Machining method of porous thin-wall protective tube with large length-diameter ratio

A technology with large aspect ratio and processing method, which is applied in the processing field of porous thin-walled protective pipes with large aspect ratio, can solve the problems of unrefined processing requirements, low processing efficiency, low processing accuracy, etc. The effect of improving machining efficiency and reducing machining position error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The material used for the Φ30mm×1008mm protective pipe is No. 45 high-quality structural steel.

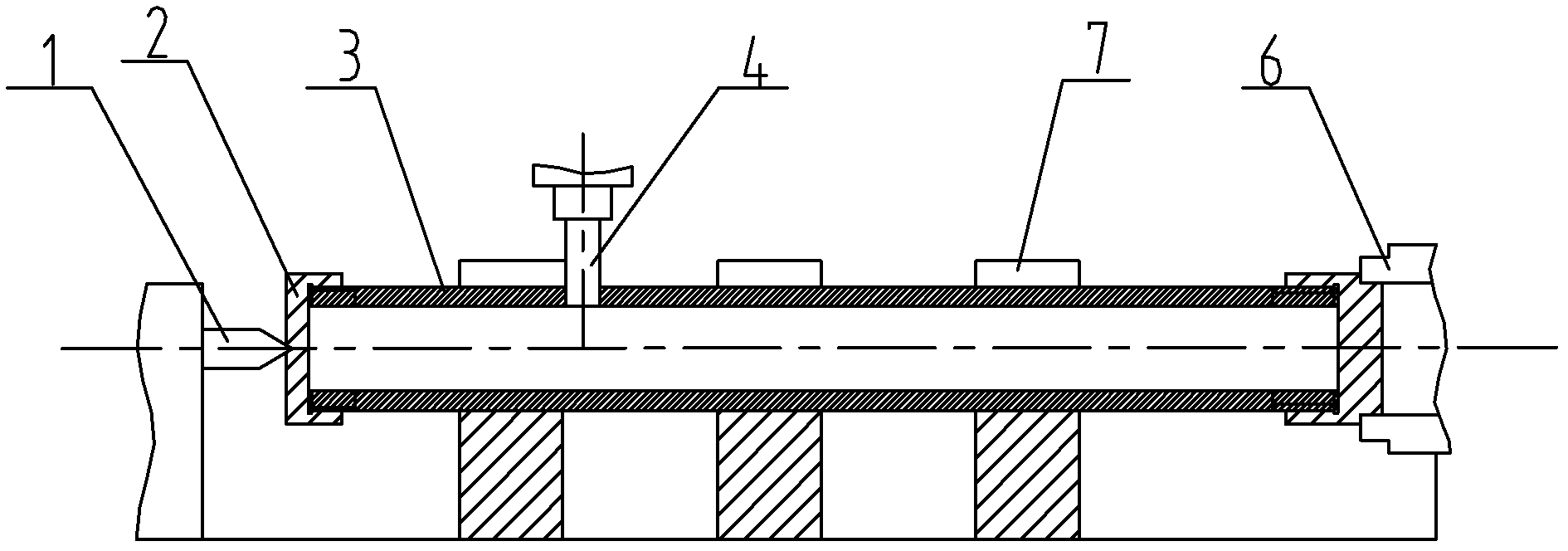

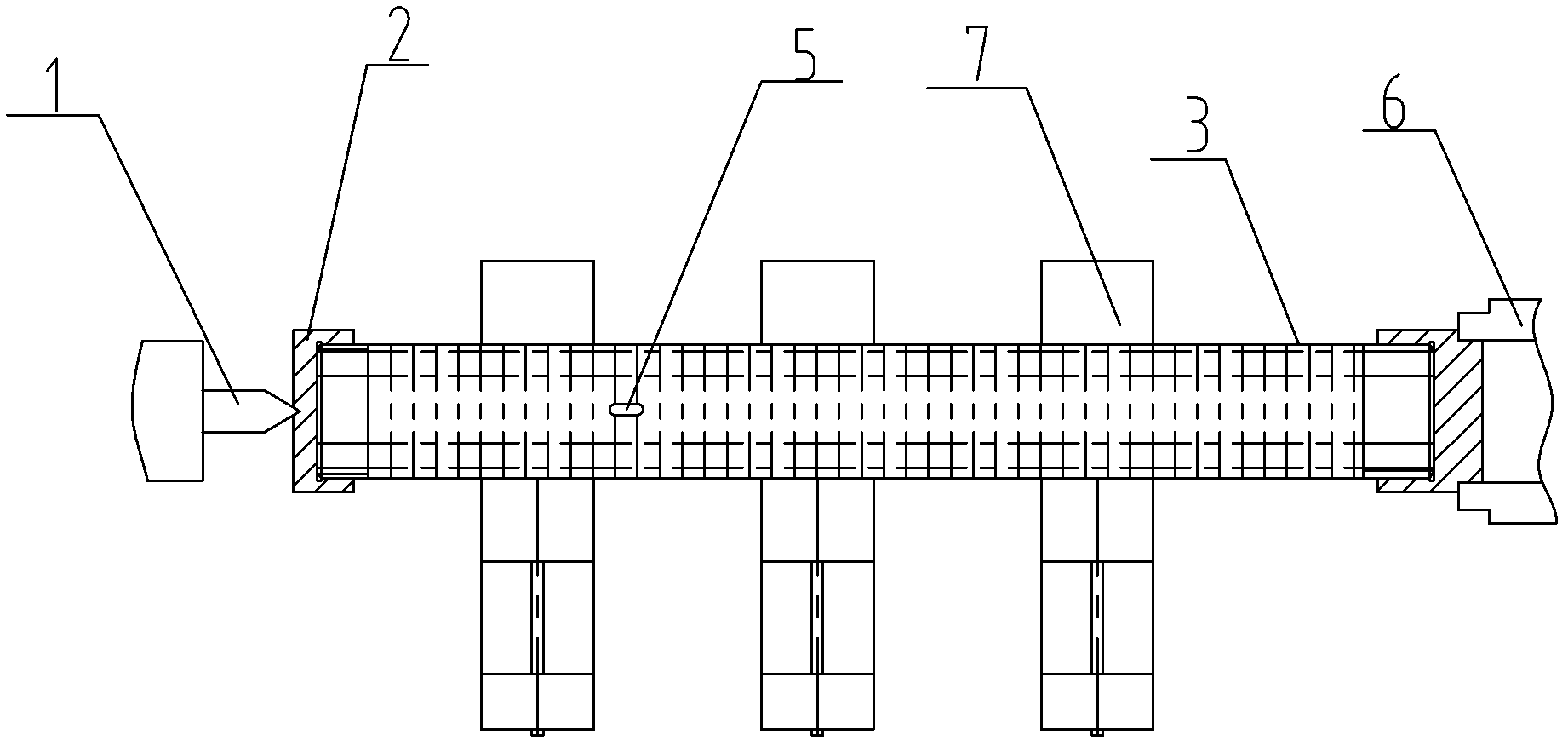

[0029] Using domestic vertical CNC milling machine, the process of tube protection processing is as follows:

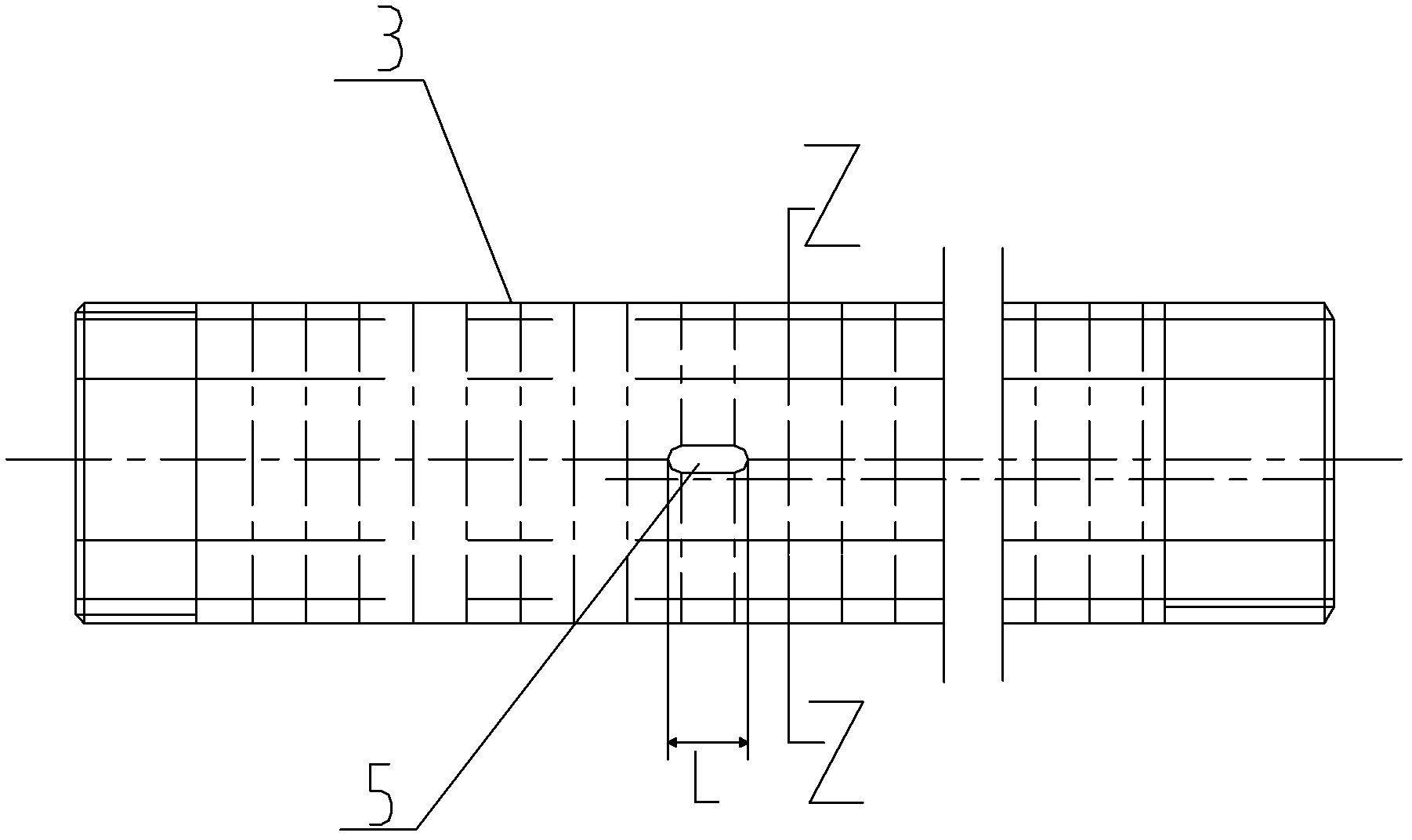

[0030] 1) Pipe blanking: Cut the thin-walled pipe 3 with large length-to-diameter ratio into the length required for the protective pipe, and turn external threads at both ends. The length of the pipe 3 is 1008mm, the diameter of the outer circle is Φ30mm, and the length-to-diameter ratio is 33.6, the pipe wall thickness is 1.5mm;

[0031] 2) Pouring low-temperature lead-tin alloy: put the low-temperature lead-tin alloy composed of 55% lead and 45% tin according to the mass percentage into a stainless steel container, heat and melt at 210°C to become liquid; use a stainless steel spoon and funnel to pour the low-temperature lead-tin alloy The tin alloy liquid is poured into the inner hole of the pipe 3, and the two ends are blocked with threaded plugs 2, then hung...

Embodiment 2

[0037] The material used for the Φ39mm×780mm protective tube is LF6M anti-rust aluminum.

[0038] Using domestic vertical CNC milling machine, the process of tube protection processing is as follows:

[0039] 1) Pipe blanking: Cut the thin-walled pipe 3 with large length-to-diameter ratio into the length required for the protective pipe, and turn external threads at both ends. The length of the pipe 3 is 780mm, the outer diameter is Φ39mm, and the length-to-diameter ratio is 20. The wall thickness of the pipe is 1.5mm;

[0040] 2) Pouring low-temperature lead-tin alloy: put the low-temperature lead-tin alloy composed of 65% lead and 35% tin according to the mass percentage into a stainless steel container, heat and melt at 260°C to become liquid; use a stainless steel spoon and funnel to pour the low-temperature lead-tin alloy The tin alloy liquid is poured into the inner hole of the pipe 3, and the two ends are blocked with threaded plugs 2, then hung vertically, cooled and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com