Printer feeding device

A technology of feeding device and printing machine, applied in printing machine, rotary printing machine, printing and other directions, can solve the problems of affecting the quality of printing process, unable to drive rubber roller, poor dust removal effect, etc., and achieve simple assembly, simplified structure, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

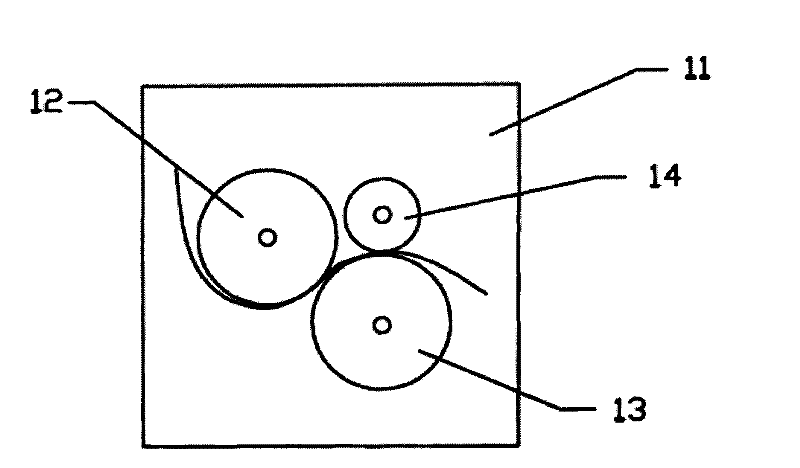

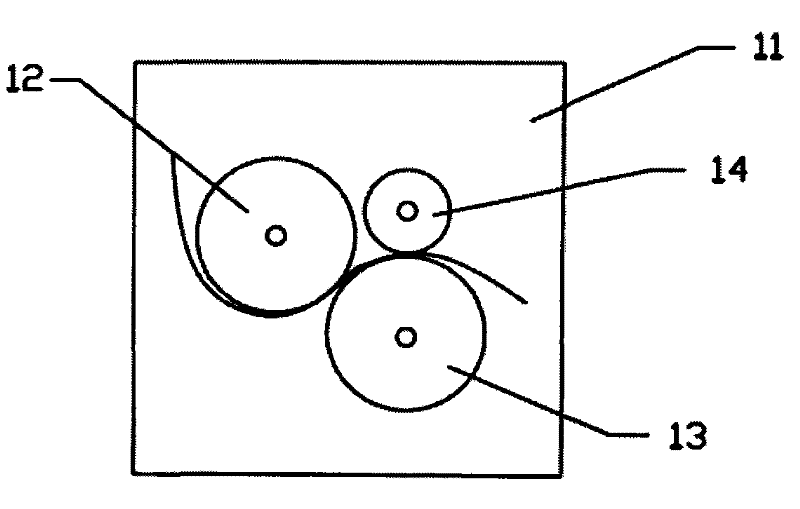

Embodiment 1

[0016] A kind of printing press feeding device of this embodiment, such as figure 1 Shown, comprise a gate-shaped frame 11, be provided with the last dust-sticking roller 12 and following dust-sticking roller 13 of axis distribution on two vertical planes parallel to each other in the gate-shaped frame 11, sticking dust roller 12 and following dust-sticking roller Roller 13 is sticky dust roller. Also be provided with a destaticizing roller 14 in the door-shaped frame 11, the axis between destaticizing roller 14 and following sticking dust roller 13 is parallel to each other, and is arranged on the same vertical plane; Last sticking dust roller 12, following sticking dust roller 13 and The static electricity removing rollers 14 can each rotate around the axis. The upper dust-sticking roller 12, the lower dust-sticking roller 13 and the static-removing roller 14 are all connected with a power device, and under the drive of the power device, the upper dust-sticking roller 12 an...

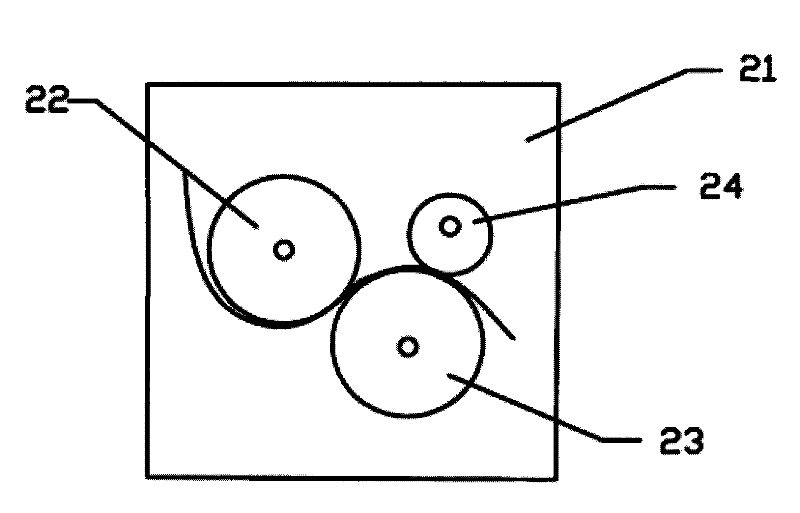

Embodiment 2

[0019] A kind of printing press feeding device of this embodiment, such as figure 2 Shown, comprise a door-shaped frame 21, be provided with the last dust-sticking roller 22 and the following dust-sticking roller 23 on the two vertical planes parallel to each other with the axes distributed in the door-shaped frame 21, the dust-sticking roller 22 and the following dust-sticking roller The roller 23 is a silica gel roller; a static removal roller 24 is also provided in the door frame 21, and the axes of the static removal roller 24 and the lower sticky dust roller 23 are distributed on two vertical planes parallel to each other; the upper sticky dust roller 22, the lower sticky roller Both the dust roller 23 and the static removal roller 24 can rotate around the axis respectively. The last dust sticking roller 22, the lower dust sticking roller 23 and the static removal roller 24 are all connected with a power device, and under the drive of the power device, the upper dust sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com