Air sampling aircraft and air sampling method

An air sampling and aircraft technology, applied in aircraft, sampling devices, motor vehicles, etc., can solve the problems of high energy consumption that cannot meet the high energy consumption of ordinary aircraft models, the flight time cannot exceed 15 minutes, and the conversion efficiency of solar panels is low. Mobility and propulsion, accurate and reliable sampling data, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

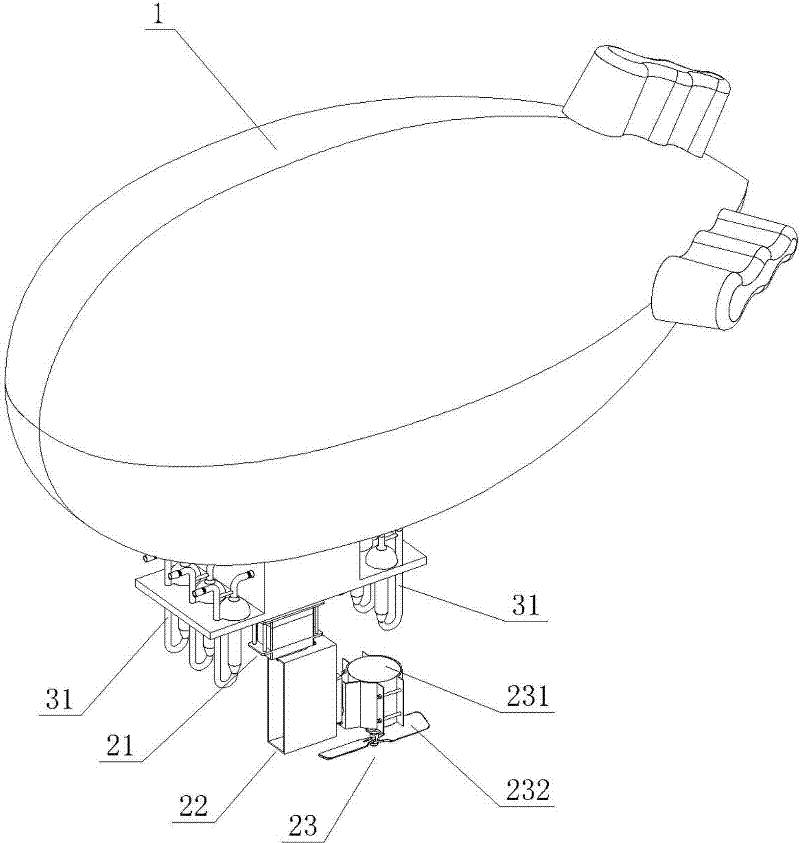

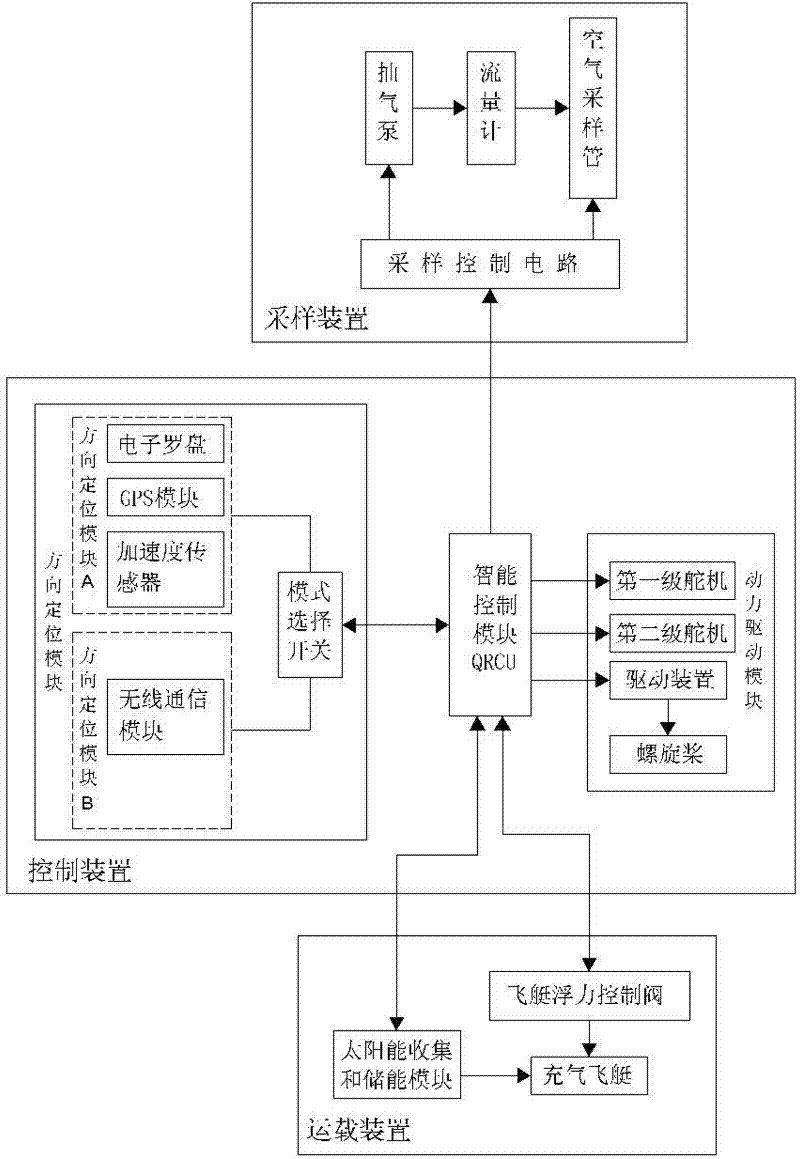

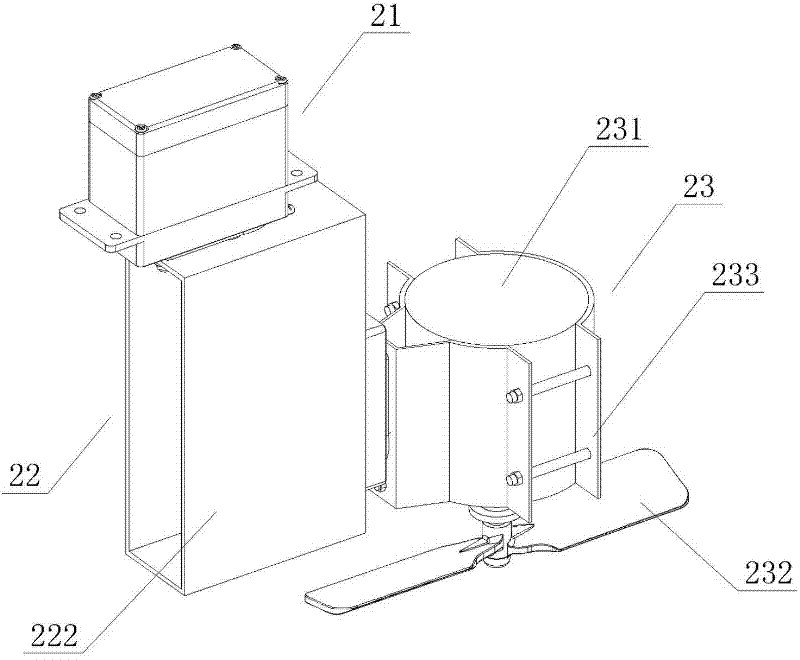

[0026] Such as Figure 1 to Figure 5As shown, the air sampling aircraft of the present invention includes a flight main body 1, a control device and a sampling device installed on the flight main body 1, wherein the control device includes an intelligent control module QRCU, connected with the intelligent control module QRCU for Control and adjust the flight direction of the flight body 1 and the direction positioning module for positioning the sampling position, the power drive module connected with the intelligent control module QRCU for driving the operation of the flight body 1, the air sampling aircraft described in this embodiment is controlled by the intelligent control module QRCU To coordinate control and complete various tasks, the intelligent control module QRCU is a small AT91 single-chip microcomputer, which has powerful functions and has various functions such as collection, analysis, calculation and sending data. It has fast speed, high precision and stability. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com