Zero-discharge and self-heating charring process for activated carbon preparation

A technology of activated carbon preparation and zero emission, which is applied in the field of carbonization of activated carbon, can solve problems such as environmental pollution and waste of resources, and achieve the effects of reducing environmental pollution and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

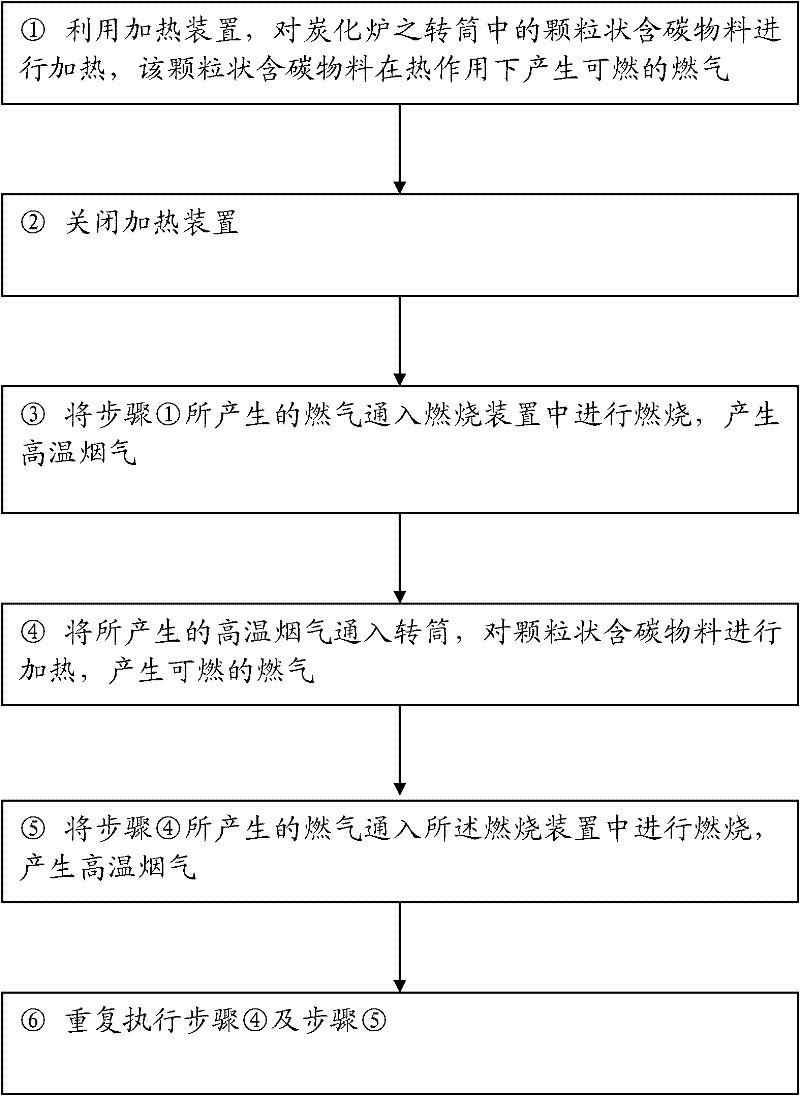

Method used

Image

Examples

no. 1 example

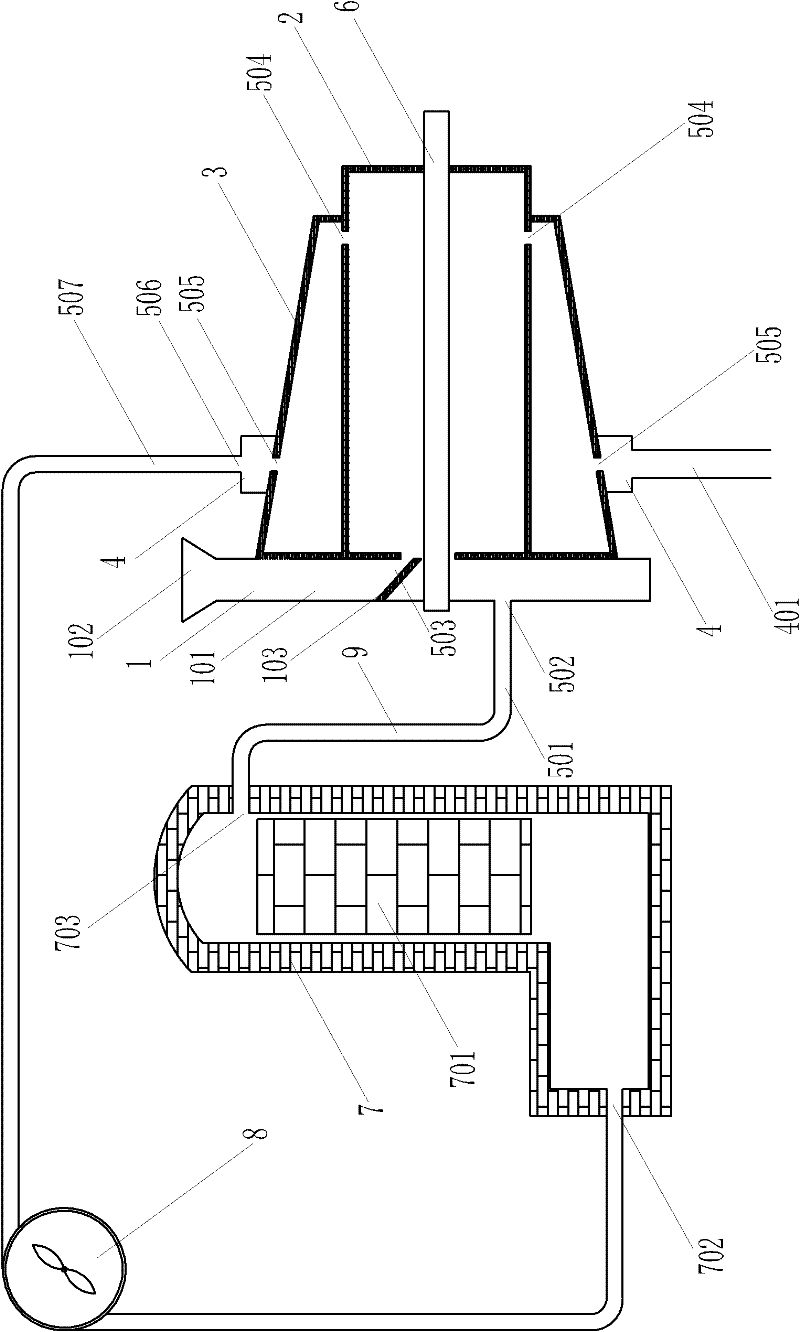

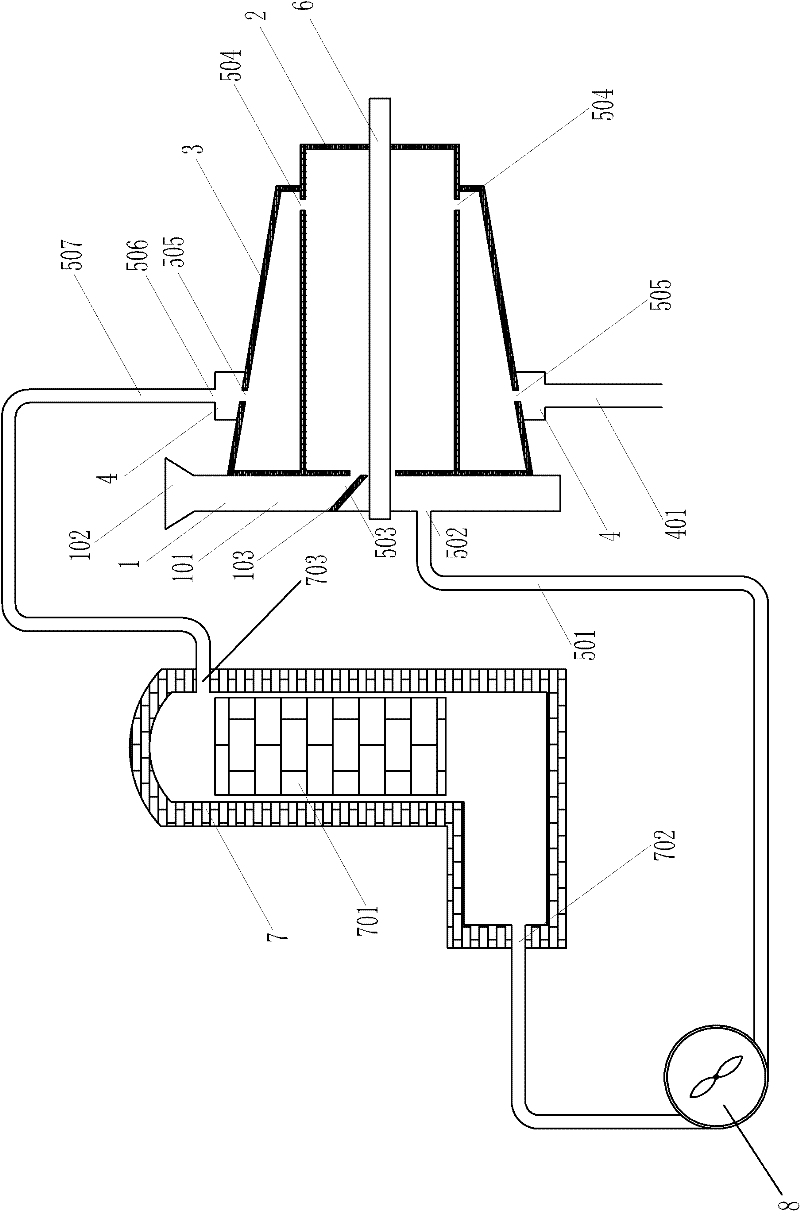

[0059] Such as figure 2 As shown, the first embodiment of the carbonization system for realizing the method of the present invention includes a carbonization furnace and a combustion device such as a combustion furnace 7 . The carbonization furnace includes a feeding device 1, a first drum 2, a second drum 3, a collection device 4, a gas-flue gas circuit structure 5, a heating device 6, and a drive for driving the first drum and the second drum to rotate. device (not shown in the figure).

[0060] Wherein, the first drum 2 is a closed cylinder with a horizontal axis, and a plurality of lifting plates (not shown) are arranged on its inner wall; a first opening 503 is provided on the end face of the head of the first drum 2; A plurality of second openings 504 are provided on the side of the tail of the rotating drum 2 , all of which are located on the same longitudinal section at the same distance from the tail end of the first rotating drum 2 .

[0061] Feed device 1 is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com