A kind of starch and polylactic acid blend and its preparation method and application

A polylactic acid and blend technology, which is applied in the field of starch and polylactic acid blends and their preparation, can solve the problems of low denitrification rate and high cost, and achieve reduced denitrification cost, strong adaptability, and denitrification rate. accelerated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

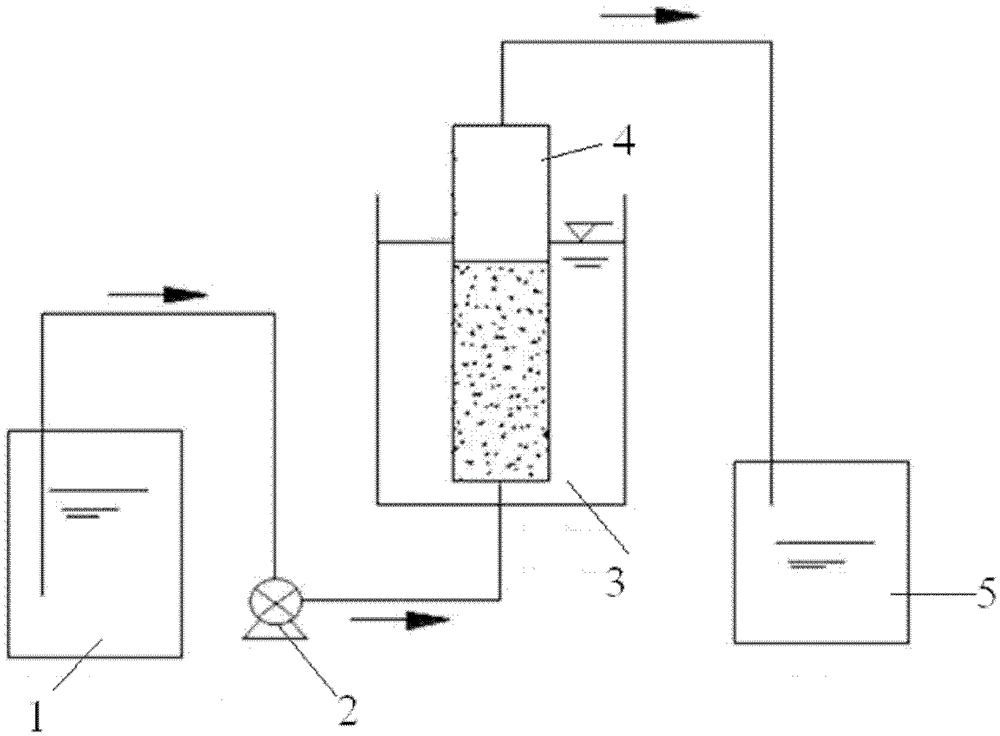

Method used

Image

Examples

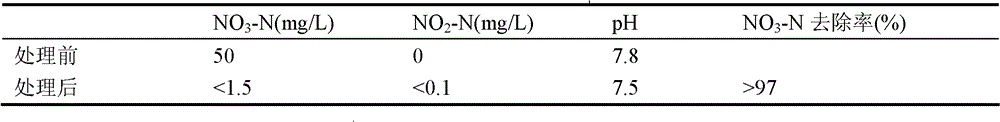

Embodiment 1

[0020] 44g of cornstarch, 45g of polylactic acid (molecular weight: 40,000), 10g of water and 1g of KH-550 silane coupling agent were stirred evenly, and extruded and granulated in a twin-screw extruder at 150°C.

Embodiment 2

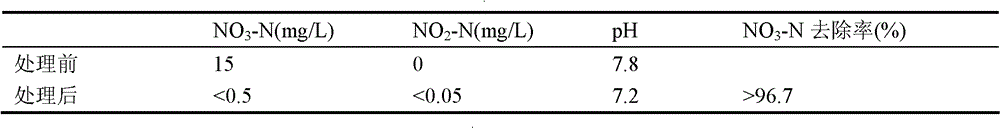

[0022] 50g of tapioca starch, 33g of polylactic acid (molecular weight: 80000), 15g of water and 2g of KH-560 silane coupling agent were stirred evenly, and extruded and granulated in a twin-screw extruder at 165°C.

Embodiment 3

[0024] After stirring 30 g of cornstarch, 55 g of polylactic acid (molecular weight: 40,000) and 15 g of water evenly, extrude and granulate in a twin-screw extruder at 175° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com