Apparatus for sludge undertaking, flexible pipe extruding dewatering and transportation, and system thereof

A technology of extrusion dehydration and conveying device, which is applied in the field of pollutant treatment in livestock and poultry breeding industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with the accompanying drawings.

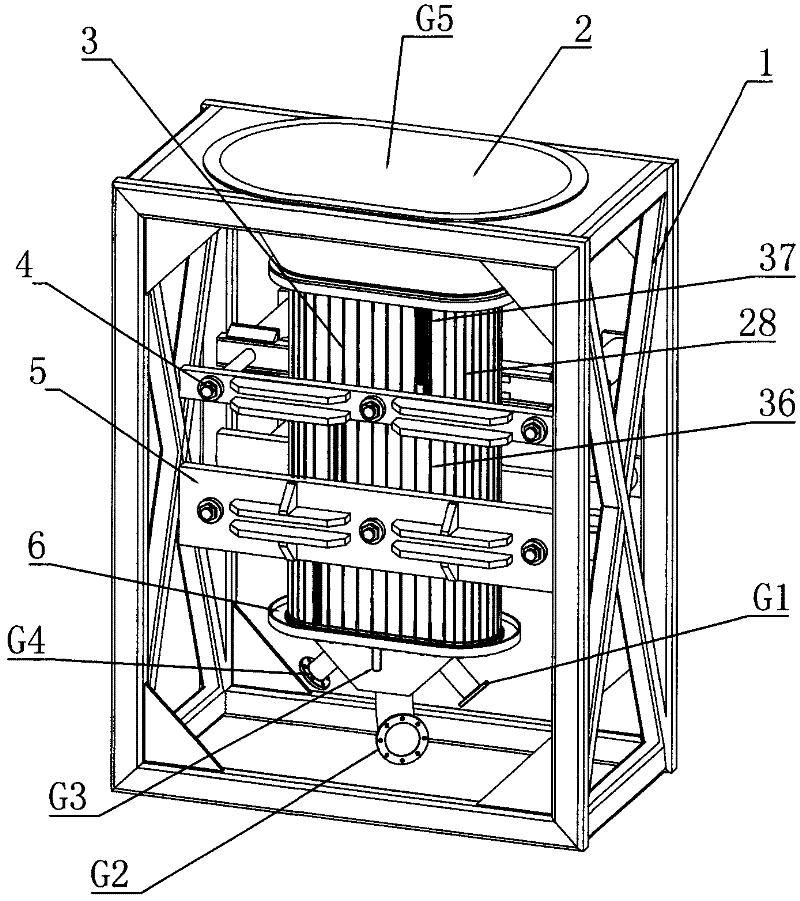

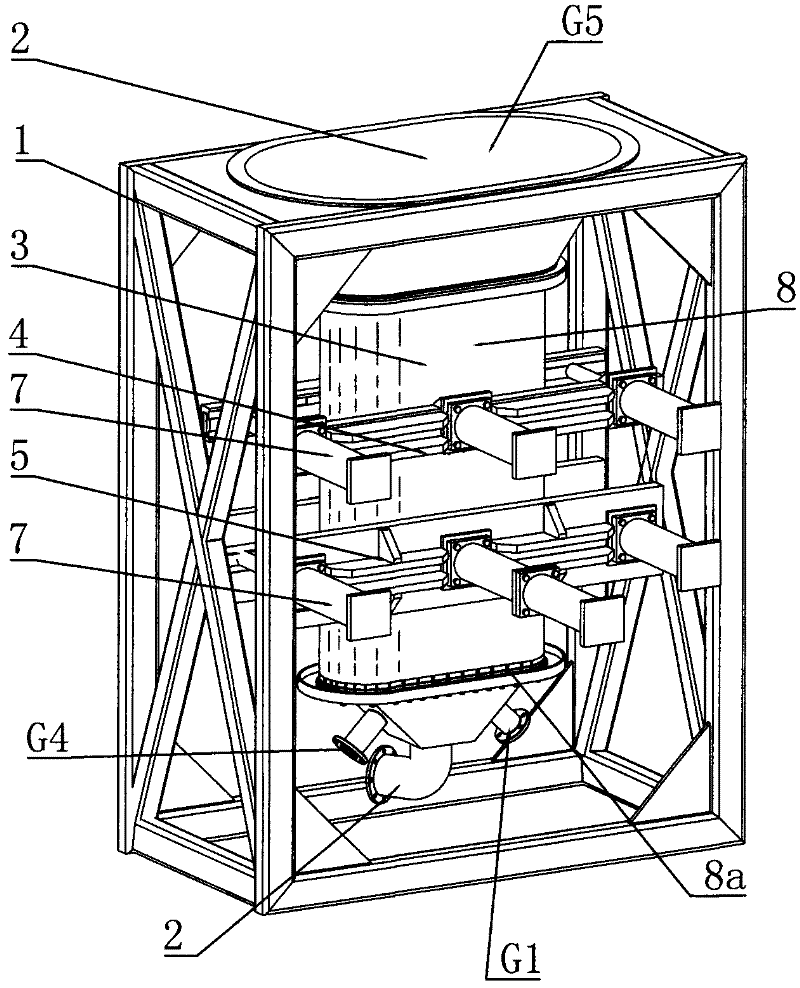

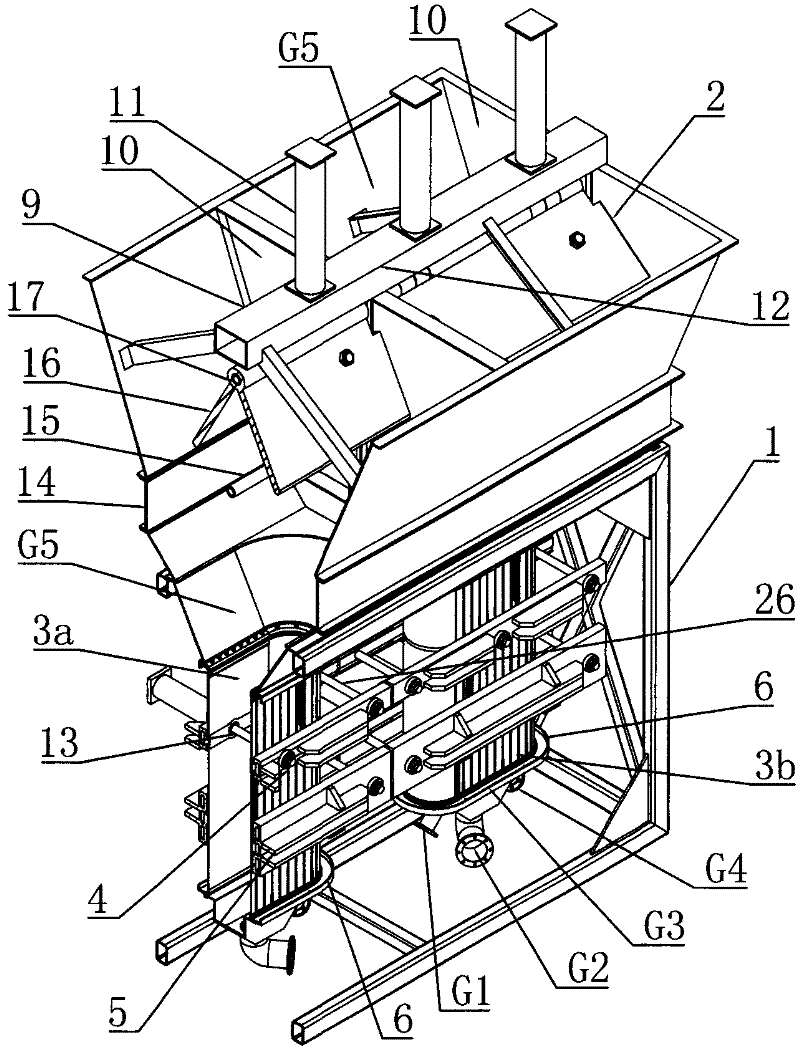

[0072] exist figure 1 , 2 , 7 to 18, 24 and 27 show the overall and system embodiment 1 of the extruding and dehydrating conveying device for flexible pipes receiving sludge.

[0073] refer to figure 1 , 2 , 7 to 18, the sludge flexible pipe extrusion dehydration conveying device includes frame 1, receiving silo 2, conveyor 3, pipeline system, filtrate discharge system and control system, and is integrated into a mechanical and electrical integration automatic sewage receiving Mud flexible pipe extrusion dehydration conveying device; the conveyer includes a flexible pipe filter chamber, a filter chamber opening and closing mechanism 4 and an extrusion mechanism 5; the extrusion mechanism includes an extrusion splint structure and an extrusion force generating mechanism, and the extrusion splint structure includes front and rear Splint 27; the flexible tube filter c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com