Method and apparatus for manufacturing pure spirit

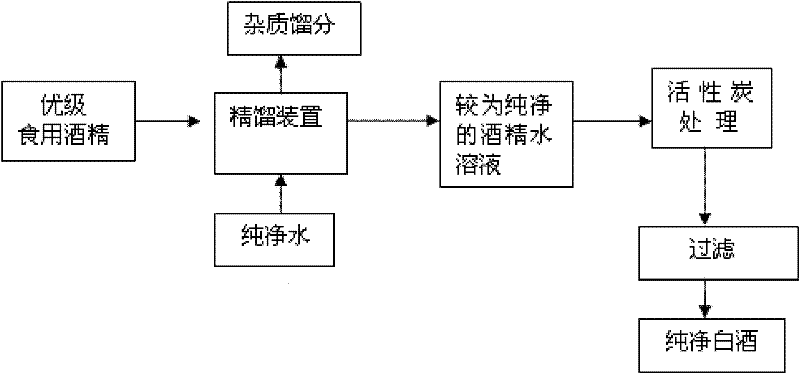

A pure and white spirit technology, applied in the preparation of alcoholic beverages, etc., to achieve good separation effect, low cost, and avoid the troublesome effect of refining treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

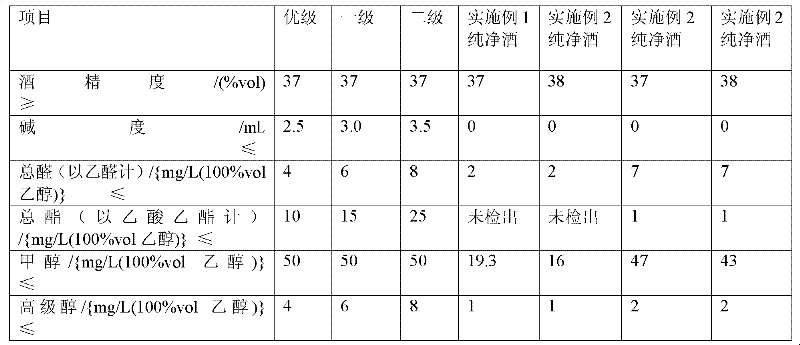

Examples

Embodiment 1

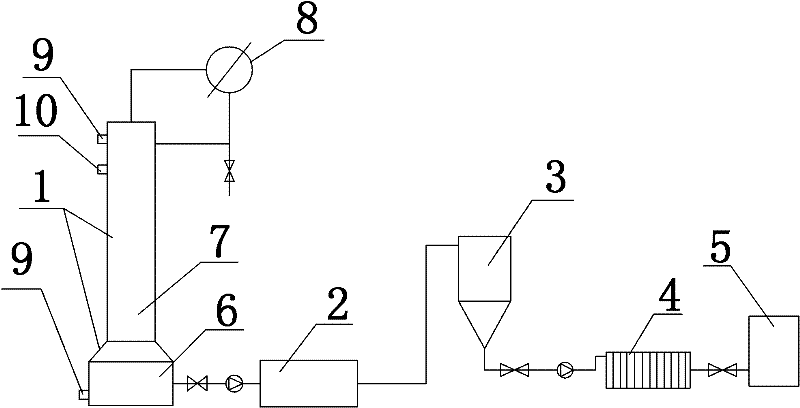

[0041] Such as figure 2The shown device for producing pure liquor comprises a rectification device 1, a heat exchanger 2, an activated carbon adsorption tank 3, a filter device 4 and a pure liquor storage tank 5, and the described rectification device 1 includes a distillation still 6, a packing rectification Tower 7 and condenser 8, the top of distillation still 6 is connected with the bottom of packing rectification tower 7, and the steam inlet of condenser 8 is connected with the steam outlet of packing rectification tower 7 tower tops, and the outlet of still 6 It is connected with the feed port of the heat exchanger 2, the discharge port of the heat exchanger 2 is connected with the feed port of the activated carbon adsorption tank 6, and the discharge port of the activated carbon adsorption tank 6 is connected with the feed port of the filter device 4, pure The feed port of the liquor storage tank 5 is connected with the feed port of the filtering device 4; the bottom o...

Embodiment 2

[0045] The device for manufacturing pure liquor as described in Example 1, the difference is that the rectifying tower 7 is a sieve plate rectifying tower 7, with 36 layers of trays in total, and the edible alcohol feed port 10 is located at the middle and upper part 24 of the rectifying tower. Between the 25 trays, the plate spacing is 300mm, the top of the sieve tray rectification tower 7 is provided with a pure water inlet 9, and the diameter of the sieve tray rectification tower 7 is 800mm. The extraction and retention section of the sieve plate rectification tower is composed of 24 trays, and the rectification section of the tray column is composed of 12 trays.

[0046] The device is suitable for continuous extraction and rectification operation. First, fill the still with pure water, then heat the still until the water vapor rises to the condenser at the top of the rectification tower, and then turn on the cooling water of the condenser. , add high-grade edible alcohol t...

Embodiment 3

[0049] The device and method for manufacturing pure liquor as described in Example 1, the difference is that ordinary grade edible alcohol is added to the edible alcohol inlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com