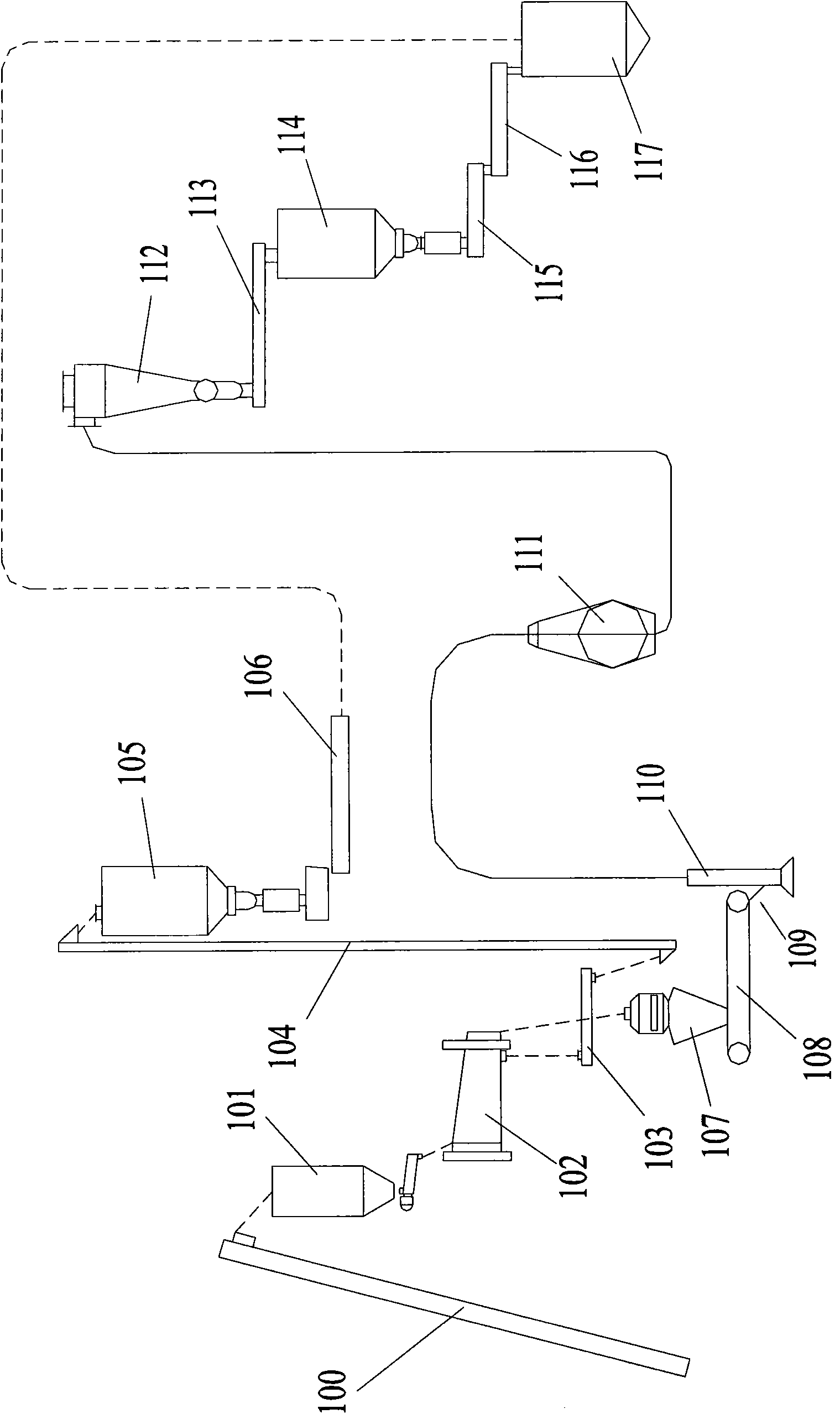

System for preparing ethanol

An ethanol and pulping technology, applied in biochemical equipment and methods, biological material sampling methods, bioreactors/fermenters for specific purposes, etc., can solve problems affecting continuous ethanol production, pipeline blockage, etc. Influence, overcome the effect of inability to remove debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

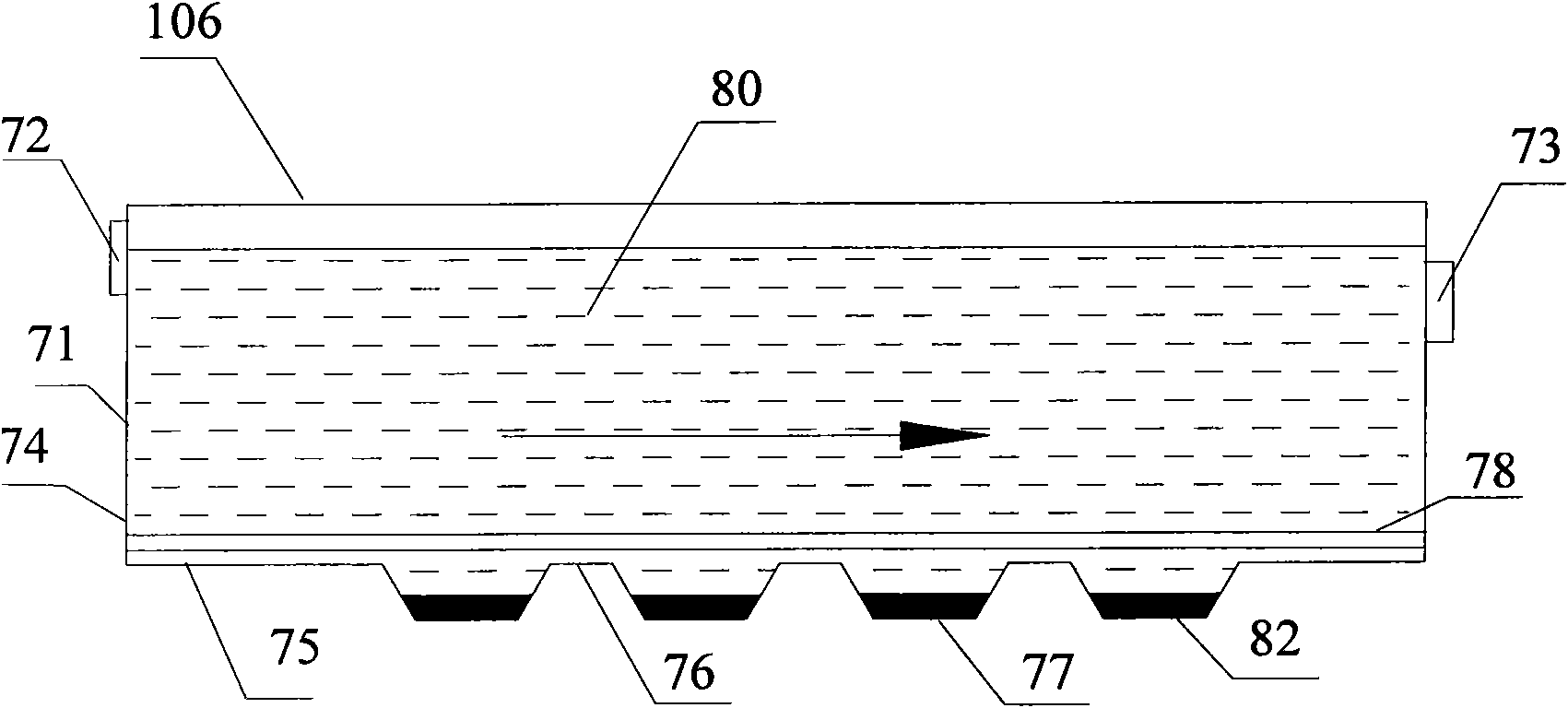

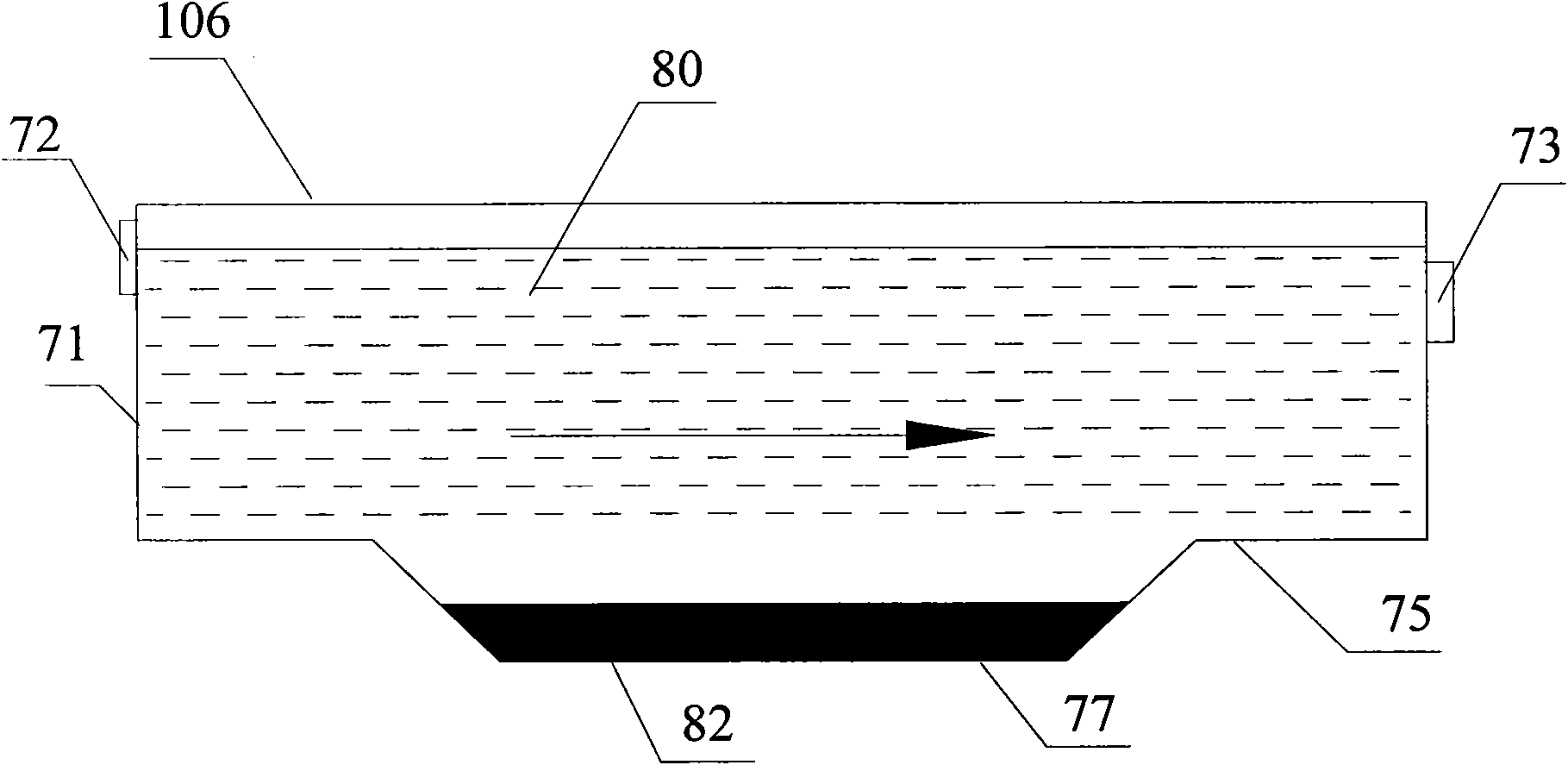

[0100] According to a preferred embodiment of the present invention, the impurity removal device further includes at least one screen, the screen is located in the conveying pipe 110 and the plane of the screen is perpendicular to the longitudinal direction of the conveying pipe 110 . Therefore, when the large particle size raw material is transported in the conveying pipe 110, the impurities doped in the large particle size raw material can be removed through the screen.

[0101] One screen can also be provided, preferably more than one, so as to give full play to the role of the screen in removing debris. The screen can be arranged in the conveying pipe 110 in various ways. For example, the screen can be fixedly arranged (such as welding, snap fitting, etc.) on the inner surface of the side wall of the conveying pipe 110.

[0102] However, in order to be able to clean up the debris remaining on the screen in time to maintain the patency of the conveying pipe 110, preferably, suc...

Embodiment 1

[0128] This example is used to illustrate the fermentation unit of the present invention and its use method.

[0129] use Figure 15 The fermentation unit shown produces ethanol. The fermentation unit includes a flash tower 210, a heat source 220, an enzymolysis tank 230, a material source 240, a vacuum pump 250, a fermentation tank 260, and a condenser 280. The flash tower 210 includes a first interface 211, a second interface 212, The third port 213 and the discharge port 214, the material source 240 is connected to the flash tower 210 through the first port 211, the enzymolysis tank 230 is connected to the discharge port of the flash tower 210, and the vacuum pump 250 is connected to the second port of the flash tower 210. The interface 212 is connected, the fermentation tank 260 is connected to the enzymatic hydrolysis tank 230, the condenser 280 is connected to the top of the flash tower 210, and the heat source 220 is connected to the third interface 213 of the flash tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com