Processing method for increasing lactobionic acid yield of pseudomonas fluorescence by applying physical field enhancement policy

A Pseudomonas fluorescens, processing method technology, applied in the field of food processing, to achieve the effect of promising market prospects, easy operation, and increased production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

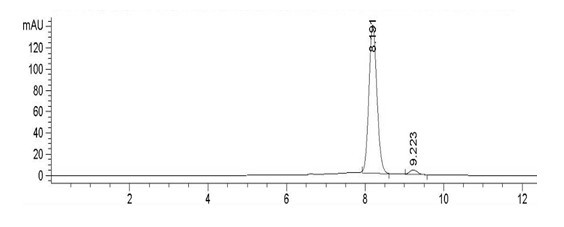

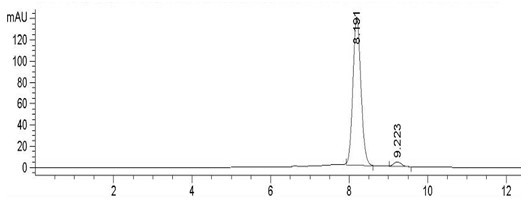

Image

Examples

Embodiment 1

[0022] Activate and inoculate Pseudomonas fluorescens SK17.001 into liquid fermentation medium (in g / 100mL, lactose 3.0, yeast extract and / or peptone 0.5, potassium phosphate 0.2, magnesium sulfate 0.2, ferrous sulfate 0.005, adjust with distilled water to pH 6.2), cultured at 30oC, 200 rpm for 18 hours and then centrifuged to obtain resting cells; then the resting cells were placed in an autoclave under the conditions of OD600nm value 0.4, lactose concentration 4%, and pH 6.0. Middle; Finally, after treatment at 100MPa and 20°C for 30 minutes, it was determined that the synthetic product lactobionic acid increased by 3.7 times.

Embodiment 2

[0024] Activate and inoculate Pseudomonas fluorescens SK17.001 into liquid fermentation medium (in g / 100mL, lactose 5.0, yeast extract and / or peptone 3.5, potassium phosphate 0.2, magnesium sulfate 0.2, ferrous sulfate 0.005, pH 6.1) After culturing at 25oC and 350 rpm for 24 hours, the resting cells were obtained by centrifugation; then the resting cells were placed in a high-pressure reactor according to the concentration of the cells at an OD600nm value of 40, a lactose concentration of 4%, and a pH of 9.0; finally, at 50MPa, After treatment at 35°C for 10 minutes, the synthetic product lactobionic acid was determined to increase by 1.9 times.

Embodiment 3

[0026] Activate and inoculate Pseudomonas fluorescens SK17.001 into liquid fermentation medium (in g / 100mL, lactose 3.8, yeast extract and / or peptone 2.0, potassium phosphate 0.2, magnesium sulfate 0.2, ferrous sulfate 0.005, pH 6.0) After culturing at 40oC and 100 rpm for 12 hours, the resting cells were obtained by centrifugation; then the resting cells were placed in an autoclave according to the cell concentration of OD600nm value 12, lactose concentration 4%, and pH 4.0; finally, at 400MPa, Treated at 50°C for 60 minutes, the measured synthesis product lactobionic acid increased by 5.2 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com