Wood-plastic-perlite composite wall panel

A composite wallboard and perlite technology, which is applied to walls, building components, buildings, etc., can solve the problems of not finding modular forming structure building materials, destroying land resources, and cumbersome construction, and achieves outstanding fire performance, saving construction period, and construction. Convenient and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

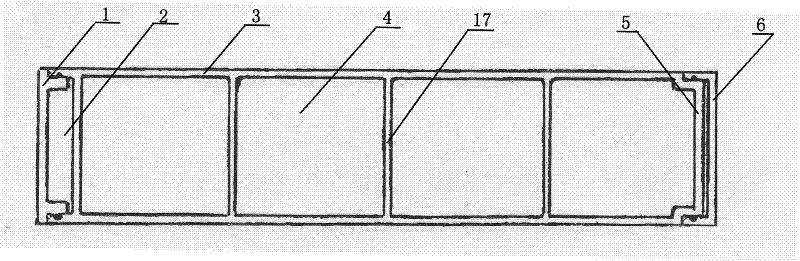

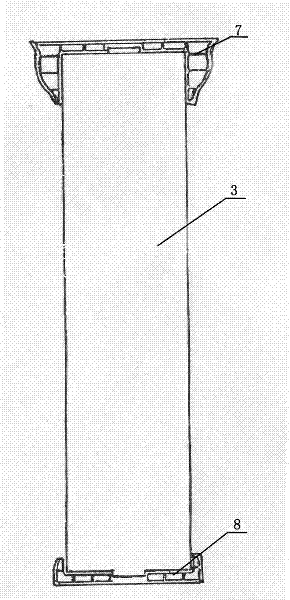

[0038] When the length of the composite wall panel frame 3 is less than the distance between the two columns and beams of the building, the U-shaped groove wall panel joint 6 or the strip plate 1 is replaced with a head, and the socket plate 15 of the head is connected to the building through the expansion bolt. Fix the object column and beam, then assemble the plug plate 16 and the socket plate 15, and finally fill the perlite composite material between the composite wall panel frame 3 and the head. In the same way, when the height of the composite wall panel frame 3 is less than that of the building, When the distance between the lower beams is lower, replace the fancy wallboard joint 7 or bottom plate joint 8 with a head.

[0039] The grids in the composite wallboard frame 3 of the present invention can be applied horizontally and vertically, only need to select the corresponding wallboard joints.

[0040] Embodiment two:

[0041] like Figure 10Shown: Repeat Example 1, w...

Embodiment 2

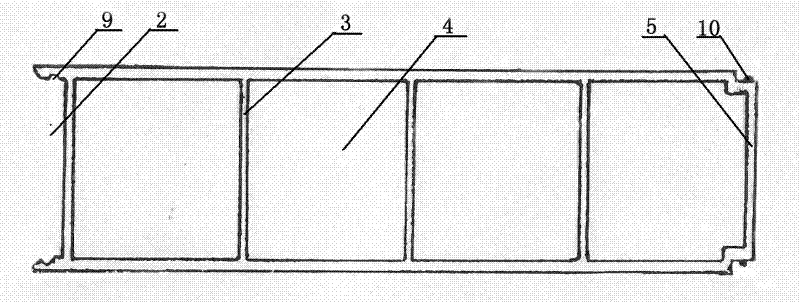

[0043] like Figure 11 Shown: Repeat Example 1, with the following differences: three composite wall panel frames 3 are arranged in a "T" shape, connected by quadrangular prism-shaped wall panel joints, and respectively passed through U-shaped Groove wallboard joint 6 and strip plate 1 are connected with building column, are connected with upper and lower beam through fancy wallboard joint 7 and floor joint 8. The symmetrical two sides of quadrangular prism shape wallboard joint frame body 12 are rectangular grooves identical in shape and size to cuboid groove 2, and also the same strip grooves as strip groove 9 are set on the edge of the groove, and one side of the remaining two sides is The same convex platform as the rectangular parallelepiped boss 5 in shape and size, and the same ribs as the ribs 10 on the rectangular parallelepiped boss 5 are also arranged on the convex platform. This embodiment is also applicable to the partition of larger rooms.

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com