System and method for carrying out in-situ detection on odd aberration of projection objective for photoetching machines

A technology of projection objective lens and in-situ detection, which is applied in the field of lithography machine, and can solve problems such as the detection accuracy of limited wave aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the examples and drawings, but the examples should not limit the protection scope of the present invention.

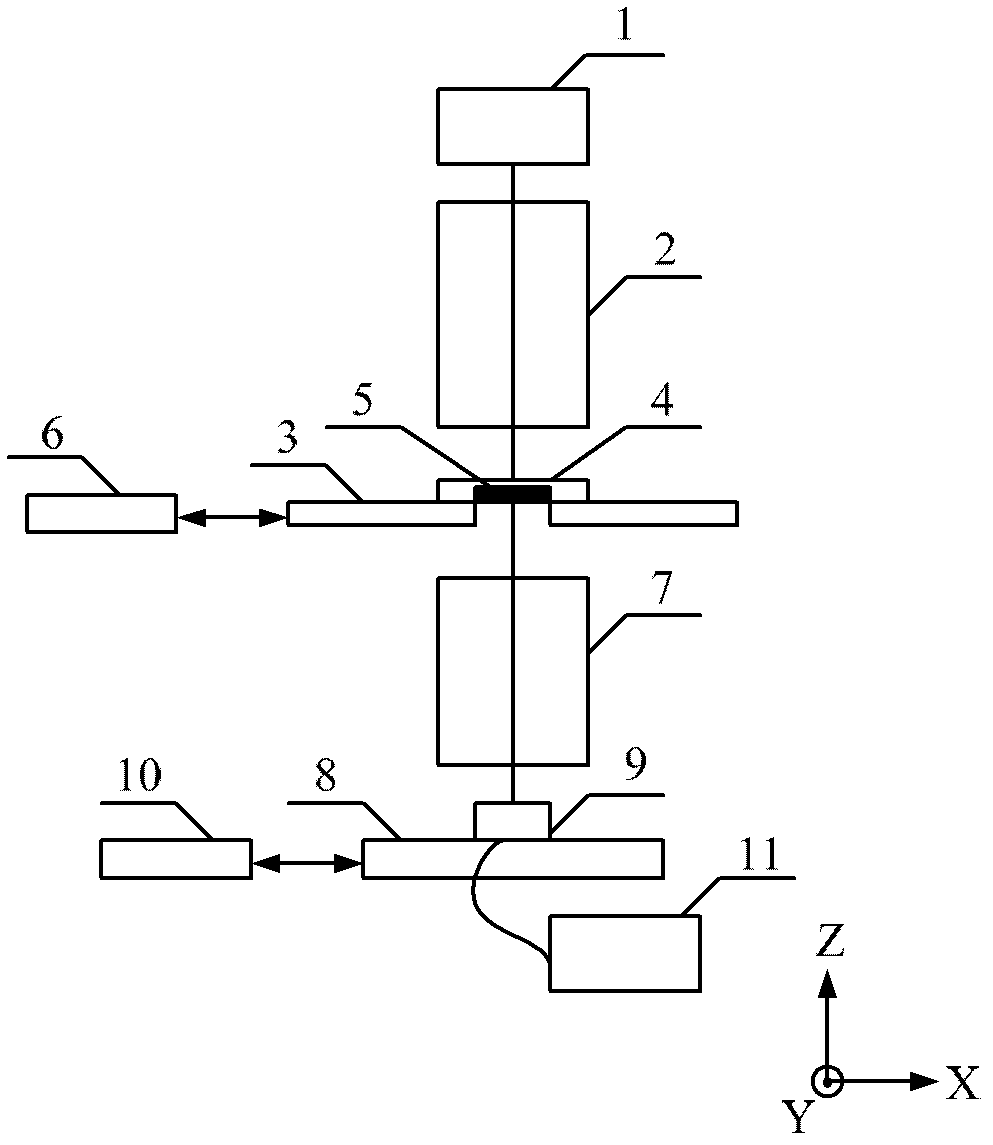

[0060] figure 1 It is a structural schematic diagram of the in-situ detection system for the odd aberration of the projection objective lens of the lithography machine of the present invention. It can be seen from the figure that the in-situ detection system for the odd aberration of the projection objective lens of the lithography machine of the present invention includes a light source 1 for generating an illumination beam, and adjusting the light emitted by the light source 1. Illumination method and partial coherence factor of the light beam and an illumination system 2 for uniformly illuminating the light beam, a mask table 3 equipped with a mask and using a positioning device 6 to realize precise positioning, a mask 4 including a detection mark 5, and an image of a mask pattern And t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com