Spinning bed gasification furnace

A gasifier and gasification chamber technology, which is applied in the field of biomass and coal gasification devices, can solve the problem that cannot meet the requirements of large-scale gasification of agricultural and forestry wastes and biomass wastes, and the requirements for fuel particle size and uniformity are very strict. The problem of high ash content in gas can reduce nitrogen content, eliminate environmental pollution and improve purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

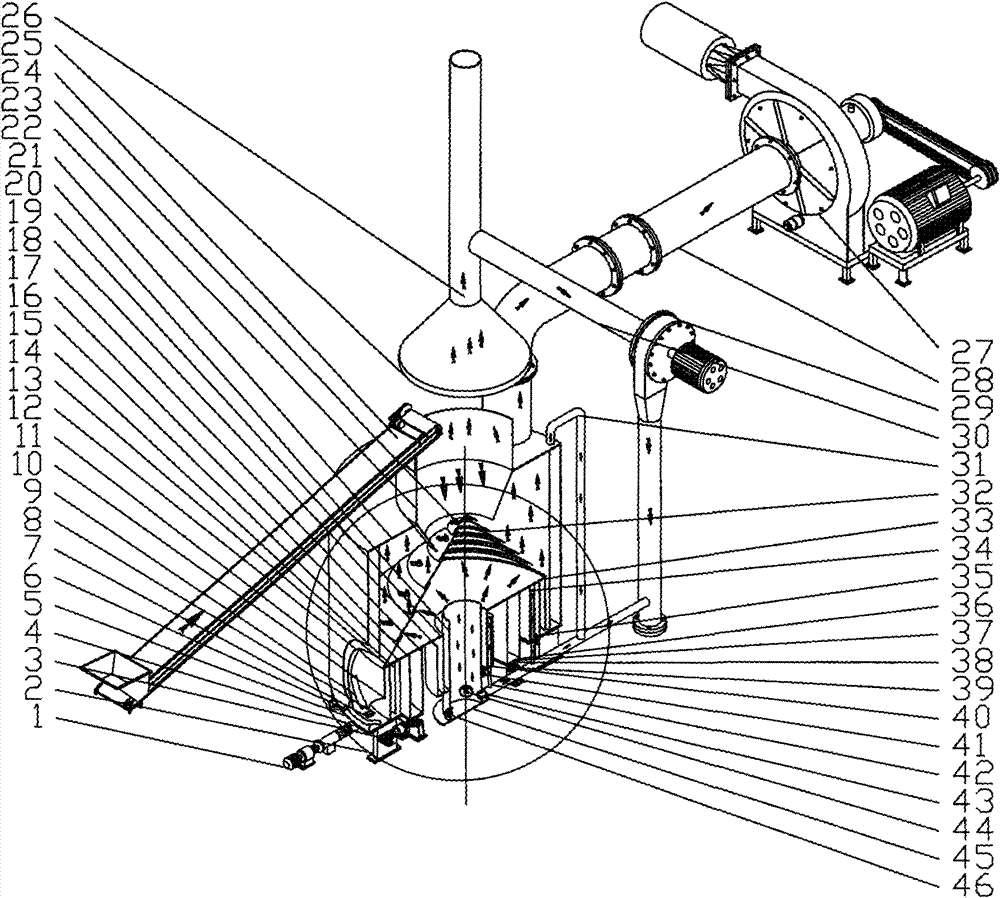

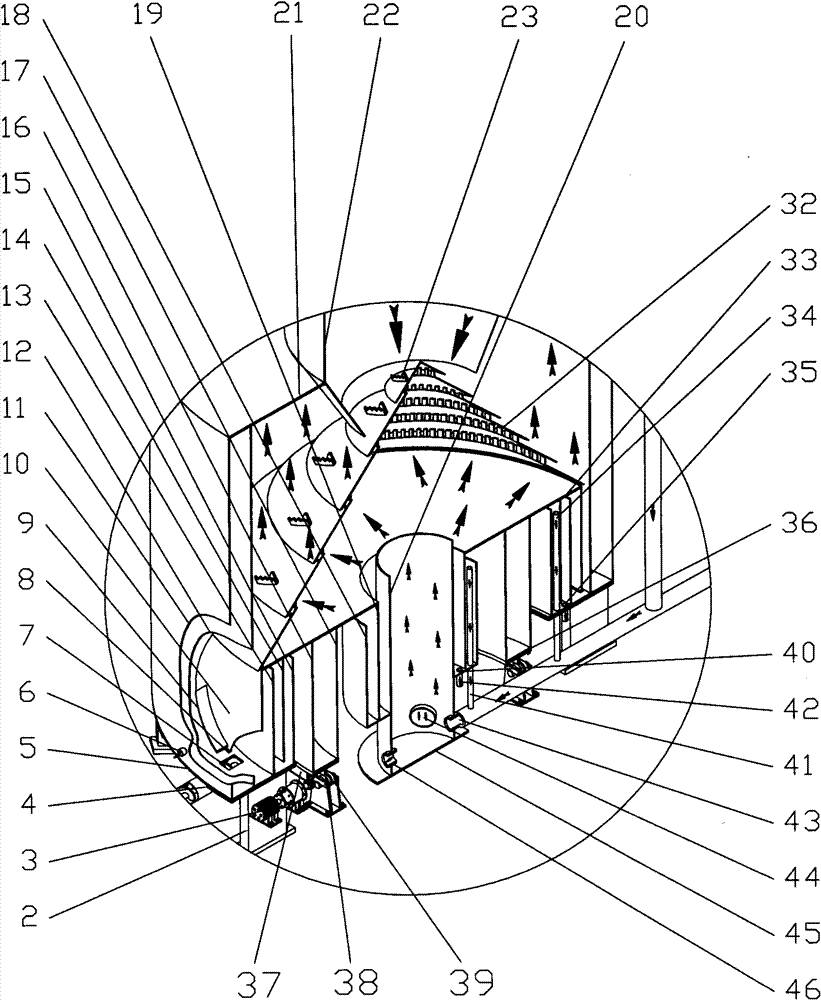

[0027] Such as figure 1 , figure 2 Shown, a kind of rotary bed gasification furnace, it comprises gasification furnace, feeding machine 24 and induced draft fan 27 and forms, and the feeding end of feeding machine 24 is connected with the feeding port on the gasification furnace, and induced draft fan 27 communicates with the gasification chamber of the gasification furnace through the gas pipe 28; the main body of the gasification furnace includes a water tank, a gasification chamber, and a gas supply mechanism. The cylindrical water tank forms the outer wall of the gasification chamber, and the gas supply mechanism is located at the bottom of the gasification chamber It communicates with the gasification chamber; the gasification chamber is a cavity surrounded by a water tank, a roof plate 21 and an air supply cover 32, the furnace roof plate 21 is welded to the top edge of the water tank, and the air supply cover 32 is located above the air supply mechanism. The air suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com