Oxygen-enriched preheating device in combustion furnace with oxygen-enriched nozzle

A preheating device and combustion furnace technology, applied in the field of combustion science, can solve the problems of acceleration, troublesome investment, large workload, etc., and achieve the effect of improving heat radiation efficiency and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

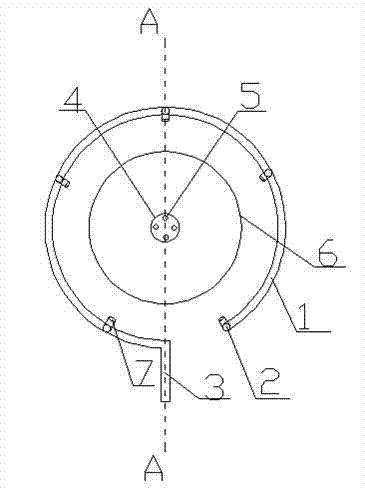

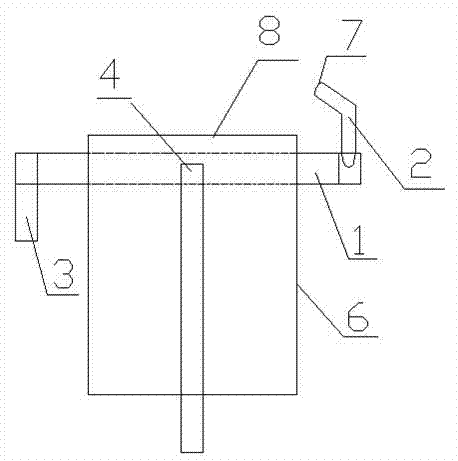

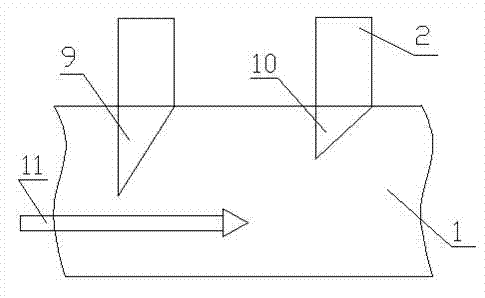

[0022] exist figure 1 In the embodiment shown in —3: the oxygen-enriched preheating pipe 1 in the furnace surrounds the burner 6 in the combustion furnace, and is attached or half-buried in the insulation layer around the burner 6, and the oxygen-enriched preheating pipe in the furnace 1 is welded with two or several oxygen-enriched nozzle pipes 2 symmetrically distributed with the burner 6, the oxygen-enriched nozzle 7 is connected to the oxygen-enriched nozzle pipe 2, and the nozzle of the oxygen-enriched nozzle 7 faces the central axis of the burner 6, And form an included angle of 10-90 degrees with the central axis of the burner 6, so that the oxygen-enriched nozzle 7 sends the oxygen-enriched gas into the area designated by the combustion flame; the oxygen-enriched nozzle tube 2 extends into the oxygen-enriched preheating tube 1 Beveled parts 9 and 10, the beveled mouth faces away from the oxygen-enriched gas flow direction 11, and the beveled part 9 that stretches into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com