Method for diagnosing regeneration failure of exhaust gas purification device

一种排气净化装置、诊断方法的技术

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

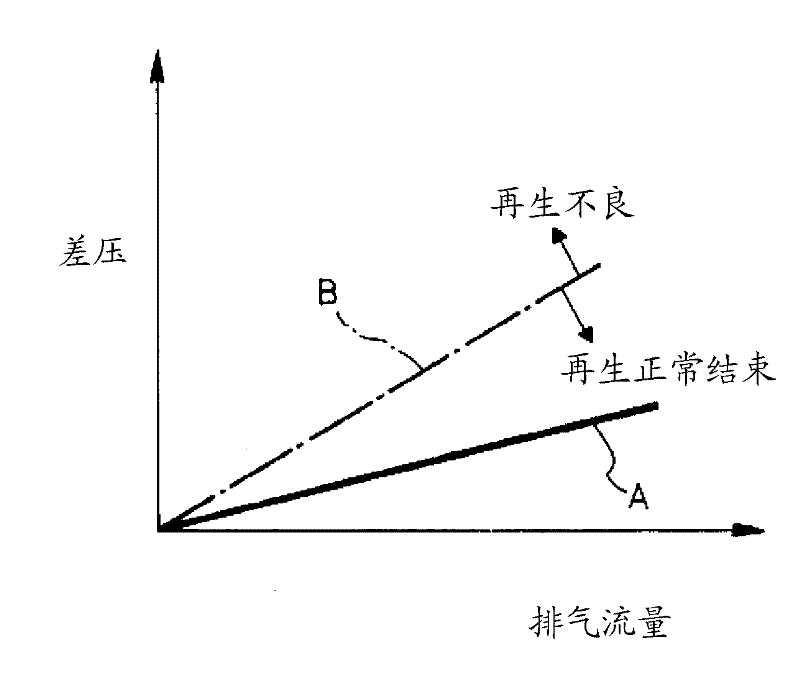

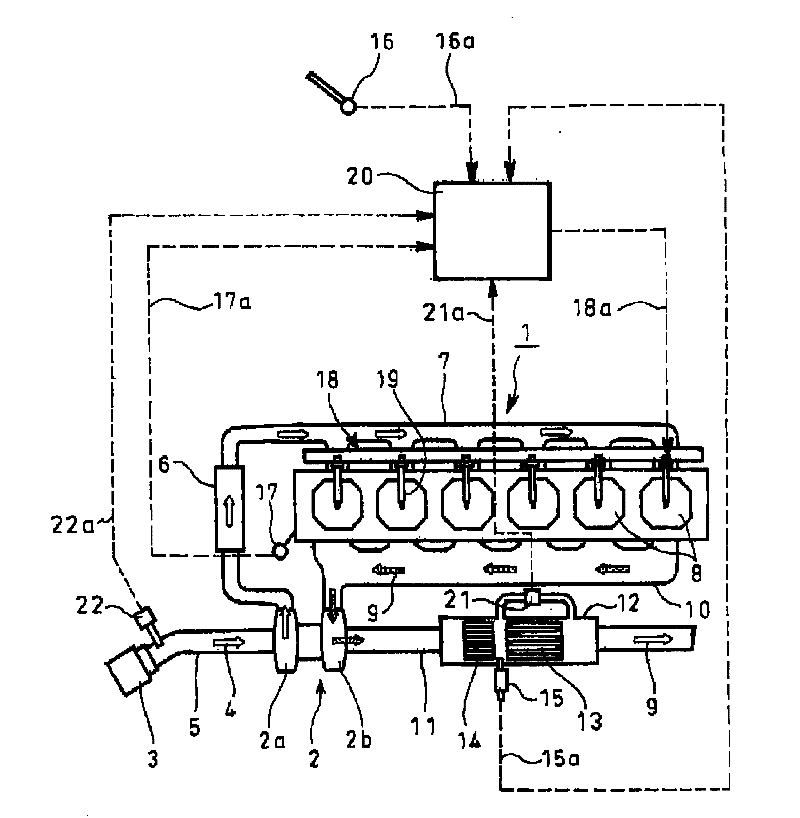

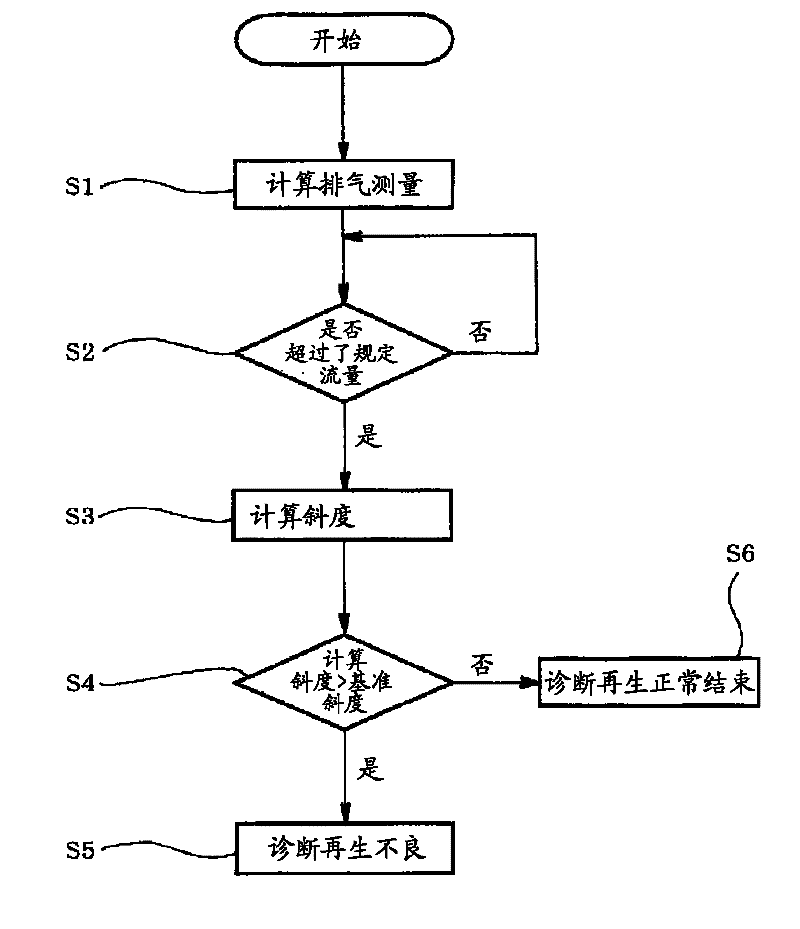

[0040] Figure 1 ~ Figure 3 An example of an embodiment of the present invention is shown. figure 1 The 1 in it represents a diesel engine equipped with a turbocharger 2, the intake air 4 introduced from the air cleaner 3 is delivered to the compressor 2a of the above-mentioned turbocharger 2 through the intake pipe 5, and after being pressurized by the compressor 2a The intake air 4 is transported to the intercooler 6 and cooled, and the intake air 4 is guided from the intercooler 6 to the intake manifold 7 and distributed to each cylinder of the diesel engine 1 (in figure 1 exemplifies the case of an inline 6 cylinder).

[0041] The exhaust gas 9 discharged from each cylinder 8 of the diesel engine 1 is sent to the turbine 2 b of the turbocharger 2 through the exhaust manifold 10 , and the exhaust gas 9 driven by the turbine 2 b is discharged outside the vehicle thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com