Ladder self-priming double layer flower pot

A self-priming, flowerpot technology, applied in automatic watering devices, container cultivation, gardening, etc., can solve the problems of porcelain flowerpots that cannot absorb water, affect product use, and easily damaged products, and achieve good water absorption. and water storage performance, meeting growth needs, and the effect of strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

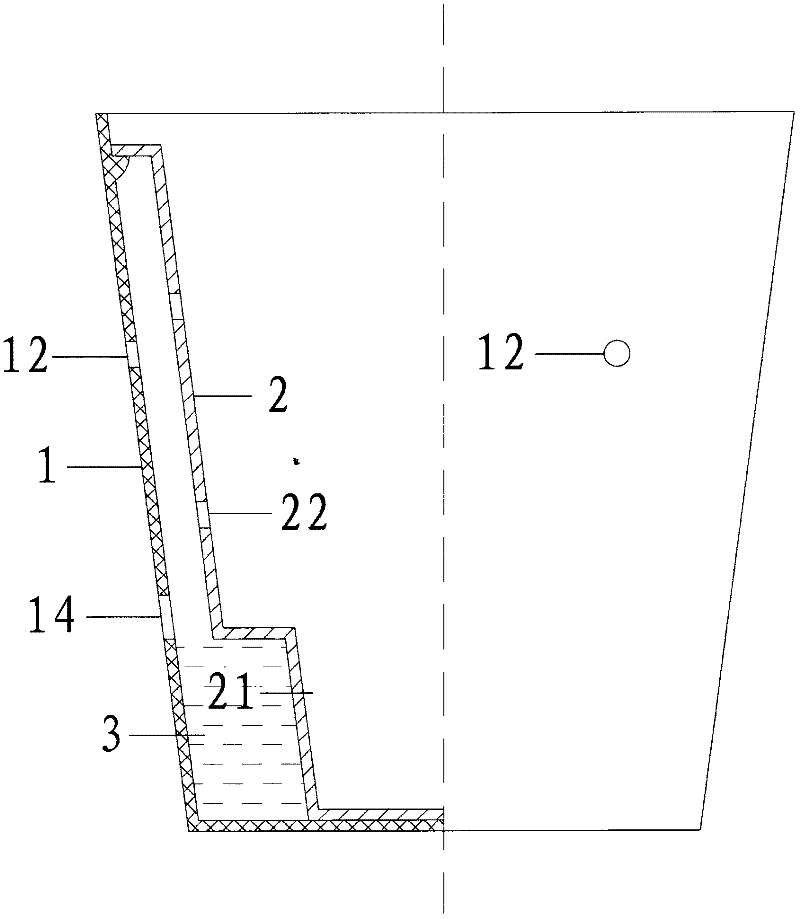

Embodiment 1

[0023] Embodiment 1: The stepped self-priming double-layer flower pot of the present invention comprises an outer pot 1 and an inner pot 2, and the outer pot 1 is provided with a water inlet 14, and the body of the outer pot 1 lower than the water inlet 14 forms a water chamber 3. The inner basin 2 is placed on the outer basin 1, and the bottom surface of the inner basin 2 is recessed to the water chamber 3 to form a water absorption part 21; the outer basin 1 is provided with air holes 12, and the air holes 12 are higher than the water inlet 14; Also have air vent 22 on the basin 2;

[0024] The outer basin is made of conventional ceramic raw materials with a water absorption rate of 3%;

[0025] The inner basin is made according to the following production steps:

[0026] First prepare the following mixed materials by weight percentage: clay 55%, secondary clay 12%, waste porcelain 10%, feldspar 11%, sawdust 12%;

[0027] Take clay, secondary clay, waste porcelain and feld...

Embodiment 2

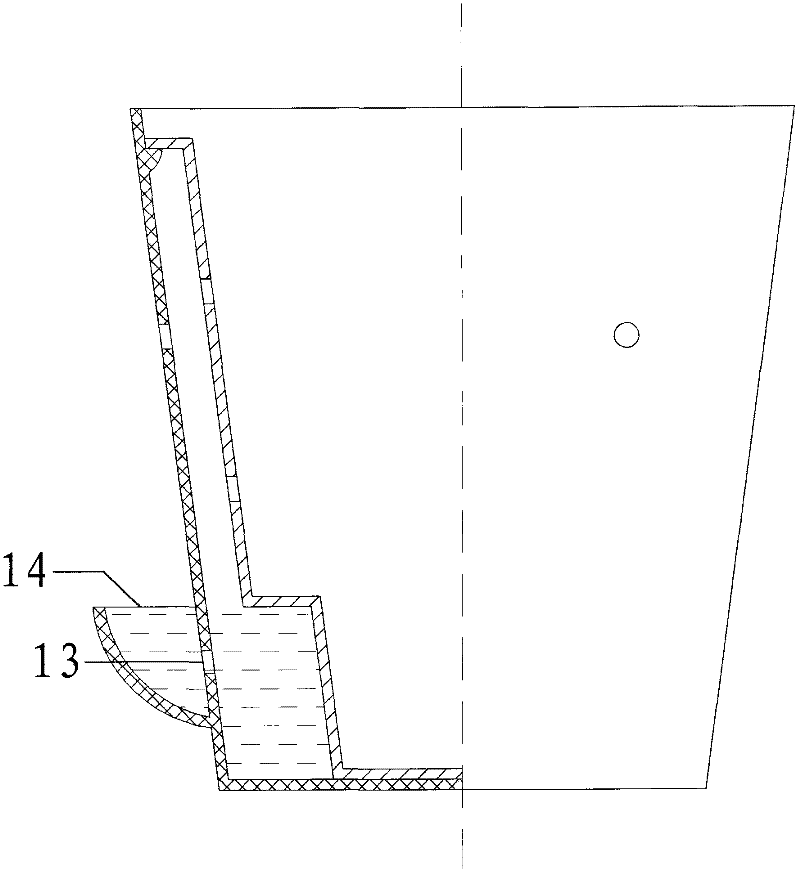

[0030] Embodiment 2: as figure 2 As shown, the difference from Embodiment 1 is that the water inlet 14 is an integral structure with the outer basin 1 and extends outwards with an upward basin wall. The water inlet hole 13.

Embodiment 3

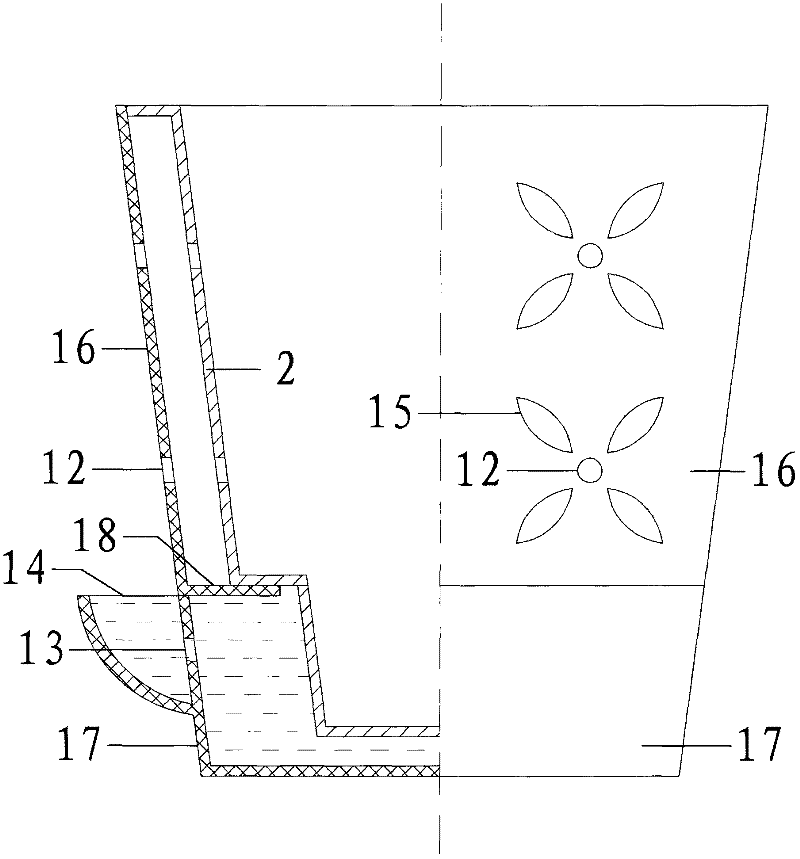

[0031] Embodiment 3: as image 3 As shown, different from Example 1, the outer basin 1 is composed of an upper basin 16 and a lower basin 17, and the bottom wall 18 of the upper basin 16 is hollow and is used as a partition to form a container with the side wall and the bottom wall of the lower basin. The water cavity 3, the inner basin 2 is mounted on the bottom wall 18 of the upper basin 16; the water inlet 14 is an integral structure with the outer basin 1 and extends outwardly to open the upward basin wall, and the outer basin 1 basin wall in the water inlet 14 has a A water inlet hole 13 communicating with the water chamber 3; a pattern 15 is provided on the outer basin 1 to decorate the air vent 12 of the outer basin 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com