Olefin Polymerization Catalyst Components

A technology for olefin polymerization and catalytic components, which is applied in the field of olefin polymerization catalyst components, can solve the problems of non-bonding, low catalyst activity, and high cost, and achieves good hydrogen adjustment sensitivity, good stereospecificity, and wide molecular weight distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

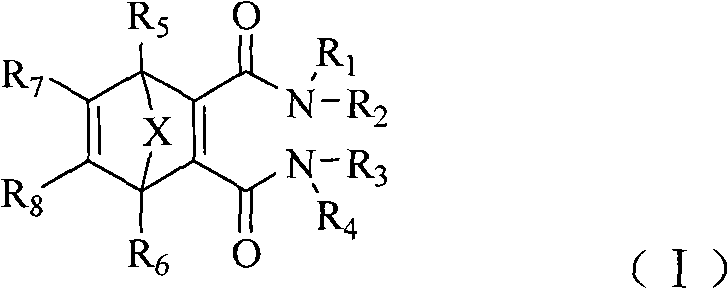

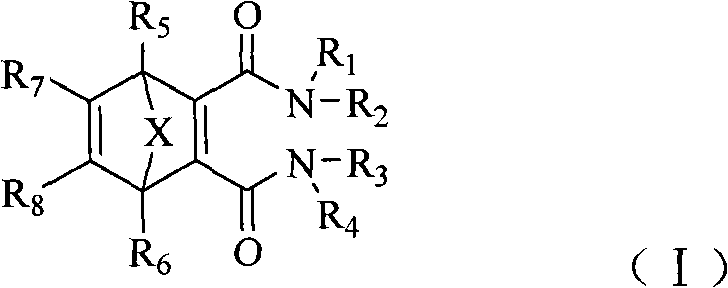

Method used

Image

Examples

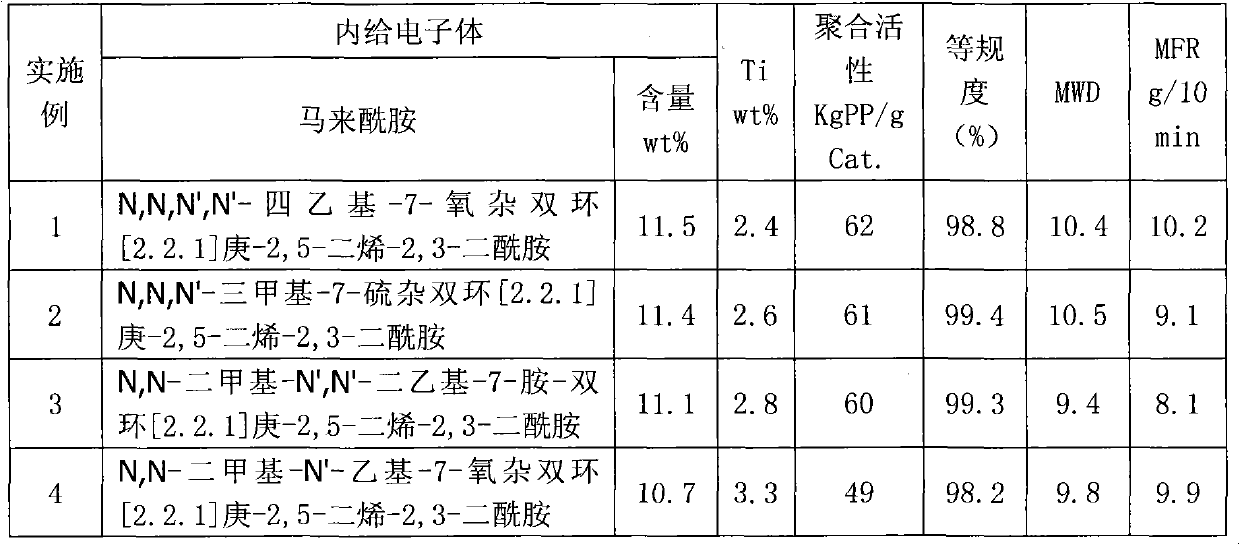

Embodiment 1-8

[0053] Under anhydrous and oxygen-free conditions, add TiCl 4 100mL and toluene 60mL, cooled to -20°C, added 10.0gMgCl 2 ·2.8CH 3 CH 2 OH spherical carrier (prepared according to the method of USP4399054); rise to 0°C within 1 hour, continue to raise the temperature to 20°C within 2 hours, continue to rise to 40°C within 1 hour; add the corresponding horseradish in Table 1 Amide compound (prepared by the aforementioned method) 7.4mmol, heated to 100°C in 1 hour, maintained for 2 hours, drained the filtrate; added TiCl 4 100mL, raised to 120°C for 1 hour, maintained for 2 hours, drained the filtrate; added 60mL of anhydrous hexane, washed 5 times in boiling state, then added 60mL of anhydrous hexane, washed 3 times at room temperature, and dried in vacuum to obtain the catalyst component .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com