Fluidized furnace device for roasting nickel-molybdenum concentrate and method for roasting nickel-molybdenum concentrate

A nickel-molybdenum concentrate and boiling furnace technology, applied in the field of boiling furnace devices, can solve the problems of poor efficiency, large consumption of reagents and high cost, and achieve the effects of increasing processing capacity, solving high organic carbon content and reducing leaching costs.

Inactive Publication Date: 2011-12-07

CENT SOUTH UNIV

View PDF7 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In order to overcome the existing process of processing molybdenum-nickel symbiotic ore, a large amount of SO will be produced 2 However, it pollutes the environment, and the technical process is complicated, the metal recovery rate is low, the valuable metal is dispersed, the reagent consumption is large, the cost is high, the benefit is poor, it is difficult to overcome the complexity of the mineral, and the technical problems of molybdenum and nickel separation in the mineral are difficult. The present invention provides Fluidized furnace device for roasting nickel-molybdenum concentrate and method for roasting nickel-molybdenum concentrate with little pollution and saving raw materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

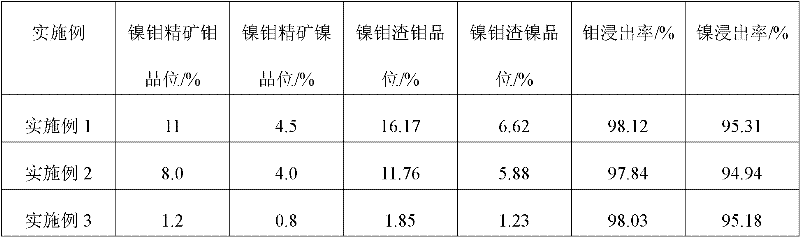

Embodiment 1

[0023] Embodiment 1: the grades of nickel and molybdenum in the nickel and molybdenum concentrate are 4.5% and 11.0% respectively;

Embodiment 2

[0024] Embodiment 2: the grades of nickel and molybdenum in the nickel and molybdenum concentrate are 4.0% and 8.0% respectively;

Embodiment 3

[0025] Embodiment 3: The grades of nickel and molybdenum in the nickel-molybdenum concentrate are 0.8% and 1.2% respectively.

[0026] Table 1

[0027]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

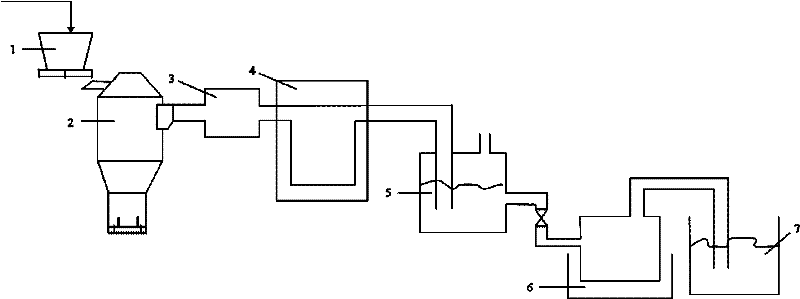

Login to View More Abstract

The invention discloses a fluidized furnace device for roasting nickel-molybdenum concentrate and a method for roasting nickel-molybdenum concentrate, comprising a feeder, a fluidized furnace body, a dust removal device, a condensing device, and an organic amine SO2 absorption device connected sequentially through pipelines, Water area heating device and contact acid making device. The technical effect of the present invention is that the nickel-molybdenum slag whose nickel-molybdenum grade is increased by about 45% can be obtained from the nickel-molybdenum concentrate obtained by flotation; for smelting, the leaching cost is greatly reduced and the processing capacity is increased; It effectively solves the problem of high organic carbon content in black rock series nickel-molybdenum concentrate; after roasting, the arsenic in nickel-molybdenum concentrate is released, which solves the harm caused by arsenic in the subsequent leaching process; the sulfur released by roasting is directly made into Sulfuric acid has become the main reagent for leaching nickel and molybdenum slag.

Description

technical field [0001] The invention relates to a fluidized furnace device for roasting nickel-molybdenum concentrate and a method for roasting nickel-molybdenum concentrate. Background technique [0002] The material composition of molybdenum-nickel-containing black carbonaceous shale ore is complex. The occurrence states and valence states of molybdenum and nickel vary and are finely dispersed. In the same ore body, there are usually many kinds of molybdenum minerals and nickel minerals. Most of the molybdenum in stone coal occurs in sulfide and is associated with pyrite, mainly molybdenite (MoS 2 ) and pyrite ((Mo, Fe) x S y ), and some other parts are mainly formed in the same phase to replace Al 3+ , Fe 3+ Others enter the mica mineral and silicate phase, and others exist in the organic matter in the form of organic state. [0003] Black carbonaceous shale is essentially a complex polymetallic mineral containing various metal elements, including valuable metal elem...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22B1/10

Inventor 孙伟胡岳华刘建东

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com