Conveyor Belt Grain Dryer

A technology for grain dryers and conveyor belts, which is applied in the direction of dryers, drying solid materials, and drying gas layout, etc., which can solve the problems of high equipment cost, difficult assembly and movement, and large loss of grain mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

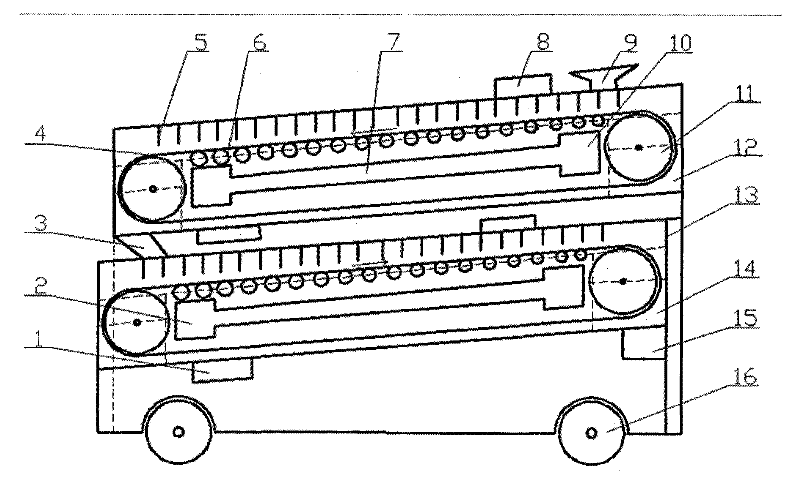

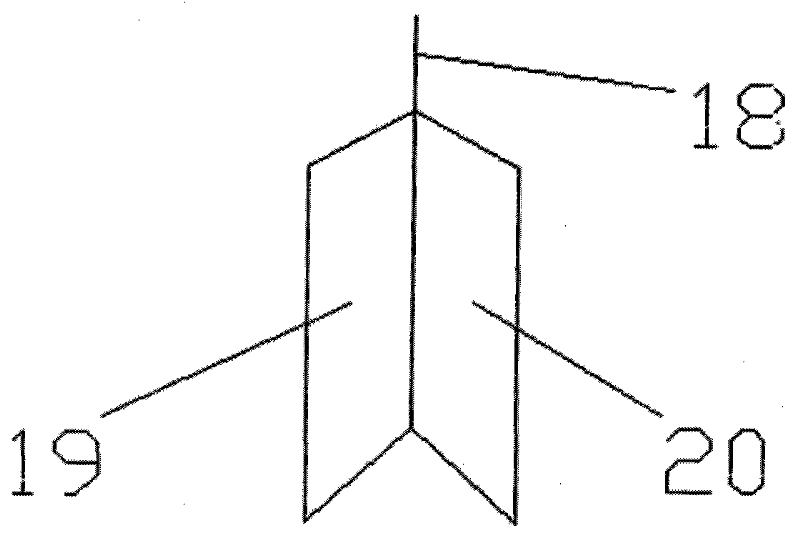

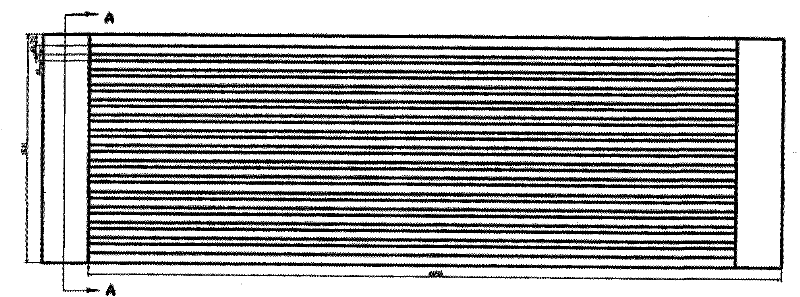

[0015] as follows figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is a conveyor belt type grain dryer, which mainly includes a first-stage drying layer 12 and a second-stage drying layer 14 . Its described first-level drying layer 12 is installed on the top of the second-level drying layer 14, and each layer is separated by a partition; the same height is installed on the inside of the partition. 5 are evenly arranged, the grain grilling device is made up of left grill 19, right grill 20 and connecting rod 18, left grill 19 and right grill 20 are all parallelogram structures, mutual symmetry, connecting rod 18 is installed on left grill 19 and right grill 20 on the center line of mutual symmetry, a steel wire conveyor belt 4 is installed below the grain picker 5, the steel wire conveyor belt 4 is wound on the pulley 11, and a plurality of supporting rods 6 with the same diameter are installed under the steel wire conveyor belt 4, and the supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com