Industrial capacitively coupled contactless conductivity online measurement device and method

A non-contact conductance and capacitive coupling technology, applied in the direction of material resistance, can solve problems such as the inability to realize simple connection of industrial metal pipes, and differences in application environments, so as to overcome electrode polarization and electrochemical corrosion, simple connection, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

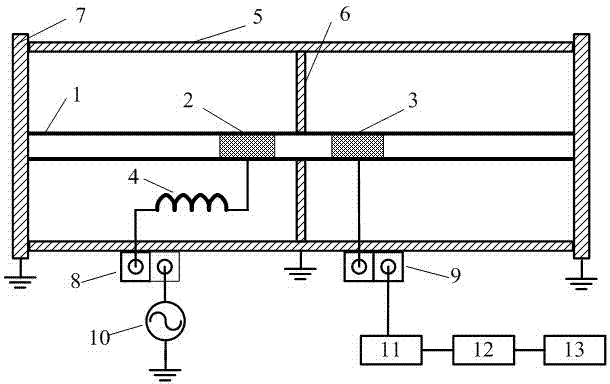

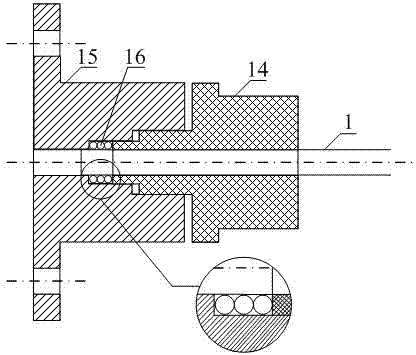

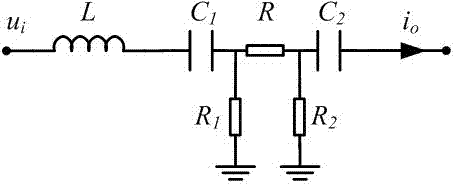

[0023] Such as figure 1 As shown, the industrial capacitive coupling non-contact conductance online measurement device includes an insulating pipe 1, an excitation electrode 2, a detection electrode 3, an inductance module 4, a metal shielding shell 5, a metal isolation plate 6, a metal flange connector 7, a first Connecting terminal 8, second connecting terminal 9, AC excitation source 10, signal processing module 11, data acquisition module 12, computer 13; two ends of the metal shielding shell 5 are respectively provided with metal flange connectors 7, and the inner horizontal direction of the metal shielding shell 5 A metal isolation plate 6 is provided, an insulating pipe 1 is arranged longitudinally inside the metal shielding shell 5, and the two ends of the insulating pipe 1 are respectively inserted into metal flange connectors 7, and the outer wall of the insulating pipe 1 and both sides of the metal isolation plate 6 are respectively provided with excitation electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com