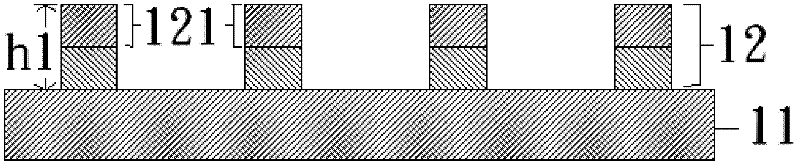

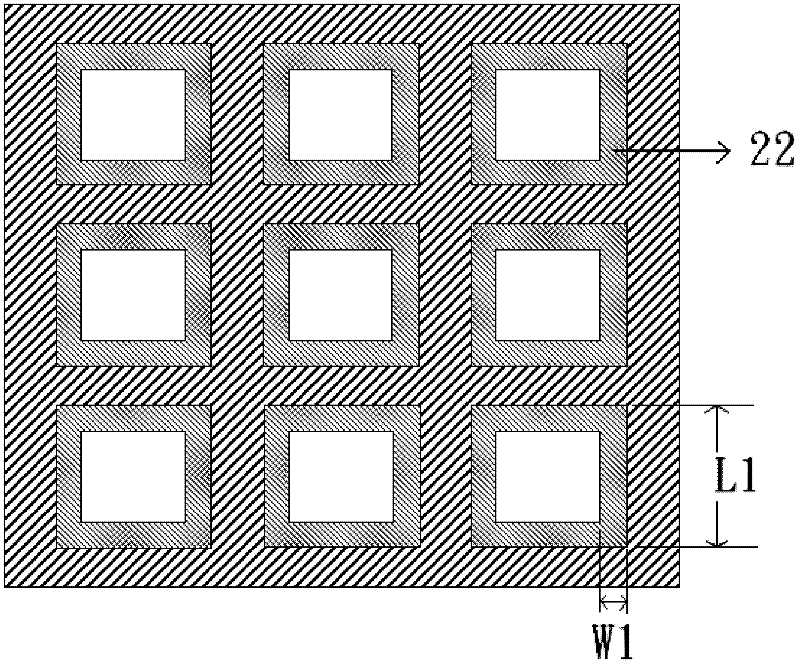

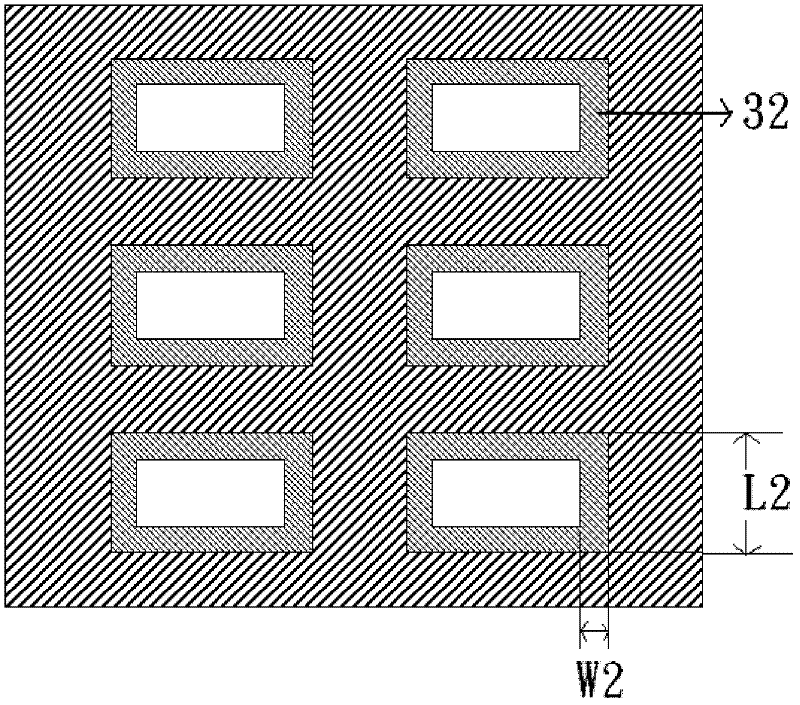

Formwork with frame, its manufacturing method and application

A frame and template technology, applied in the field of light-emitting components, can solve the problems of slow process speed, insufficient luminous efficiency, uneven film thickness, etc., and achieve the effects of fine thickness and width, improved uniformity and flatness, and high luminous power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0079] A photoresist composition (see Table 1) with the following composition was prepared, wherein the polymer binder mainly consisted of a polyacrylic binder (b1) with photocurable side chains.

preparation example 2

[0081] A photoresist composition (see Table 1) having the following composition was prepared, wherein the photoinitiator has anti-yellowing photoinitiator (c21) and (c22).

preparation example 3

[0083] A photoresist composition (see Table 1) having the following composition was prepared, to which a chain transfer agent (g1) was added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com