A kind of surimi product and preparation method thereof

The technology of a surimi product and a production method, which are applied in the field of food processing, can solve the problems of insufficient crispness in taste, high production cost of surimi products, and low elasticity of surimi products, and achieve the effect of high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

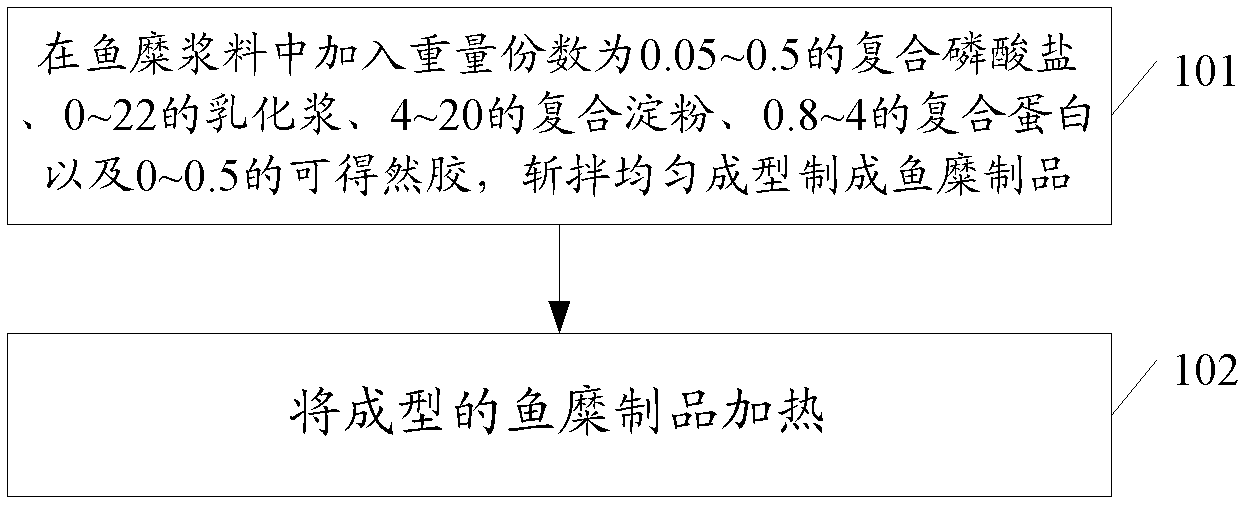

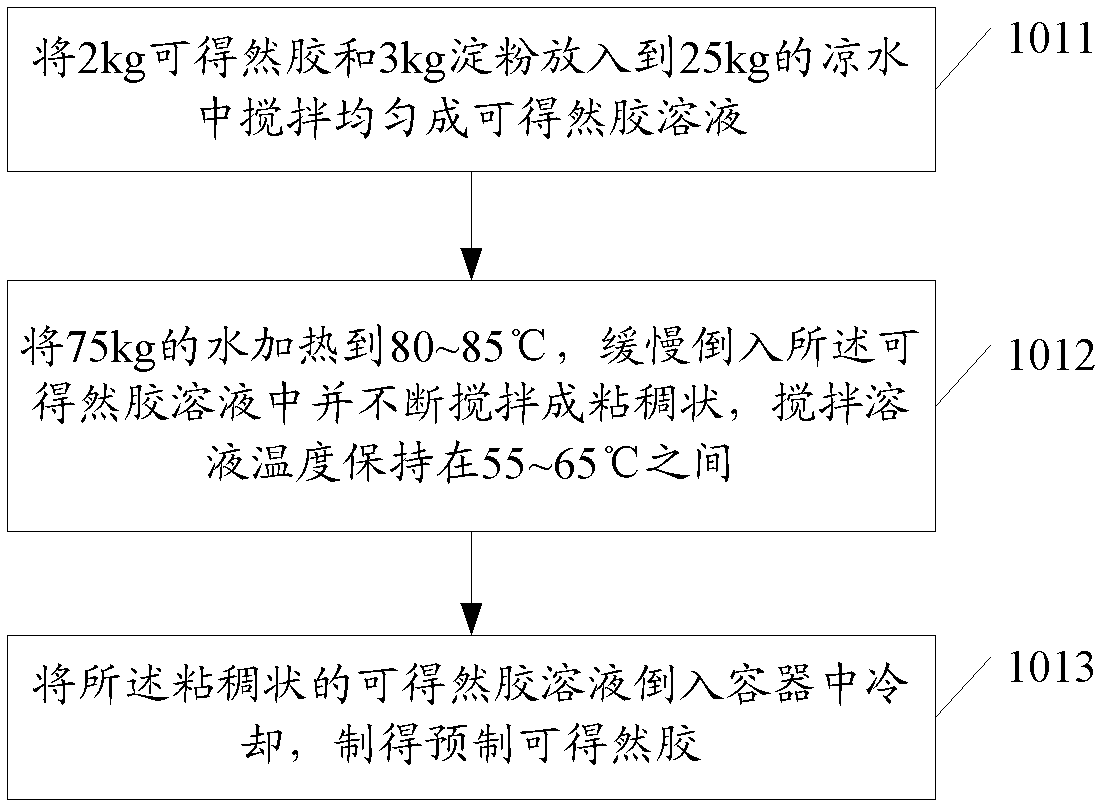

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Making fish balls

[0048] The proportions of the ingredients in the fish balls are shown in Table 1

[0049] raw material name

parts by weight

Grade A surimi

50

Complex starch

10.5

fat

5

Emulsified pulp

10

17.3

salt

1.9

2.2

garlic

1.7

complex phosphate

0.3

1

0.1

test resilience

360.185g.cm

[0050] Table I

[0051] Among them, the composite starch is composed of 20 g of corn starch and 80 g of cassava modified starch. The compound phosphate is composed of sodium tripolyphosphate, sodium hexametaphosphate and sodium pyrophosphate, and the weight ratio is: 85:12:3. The complex protein is gluten and sodium caseinate in a weight ratio of 4:1. Emulsified pulp: soy protein isolate: oil: water = 1:1.5:5

[0052] Specifically: 500g of grade A fr...

Embodiment 2

[0053] Example 2 Making fish balls

[0054] The addition ratio of each ingredient in the surimi product is shown in Table 2:

[0055] raw material name

parts by weight

Grade A surimi

50

Complex starch

10.5

fat

5

Emulsified pulp

10

16.7

salt

1.9

2.2

garlic

1.7

complex phosphate

0.3

1.5

0.2

test resilience

363.17g.cm

[0056] Table II

[0057] Specifically: the complex starch includes: 105 g of tapioca modified starch; the complex phosphate includes: sodium tripolyphosphate: sodium hexametaphosphate: sodium pyrophosphate=85:12:3; complex protein: gluten. Composition of emulsified pulp: soy protein isolate: oil: water = 1: 1.5: 5.

[0058] Half-thaw the frozen minced fish A500g cut into small pieces, put it into the Braun conditioner and add 17g garlic, use a b...

Embodiment 3

[0059] Example 3: Making fish tofu

[0060] The ratio of each raw material is shown in Table 3:

[0061] raw material name

parts by weight

Grade A surimi and surimi

43.5

Complex starch

11.4

fat

4.9

Emulsified pulp

10.9

18.5

ice protein

3.2

salt

1.8

2.2

complex phosphate

0.3

complex protein ②

3

0.3

test resilience

356.92g.cm

[0062] Table 3

[0063] Compound starch: corn starch 25g, cassava modified starch 80g; compound phosphate: sodium tripolyphosphate: sodium hexametaphosphate: sodium pyrophosphate=85:12:3; compound protein: gluten. Composition of emulsified pulp: soy protein isolate: oil: water = 1: 1.5: 5.

[0064] Half-thaw 435g of grade A frozen surimi and surimi cut into small pieces, the weight ratio of frozen surimi A and surimi is 1:1, put into Braun processor, us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elasticity | aaaaa | aaaaa |

| Elasticity | aaaaa | aaaaa |

| Elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com