Preparation method of wet compress

A technology of wet compress and wet compress, which is applied in the field of preparation of wet compress, and can solve the problems of easy deterioration of liquid patches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

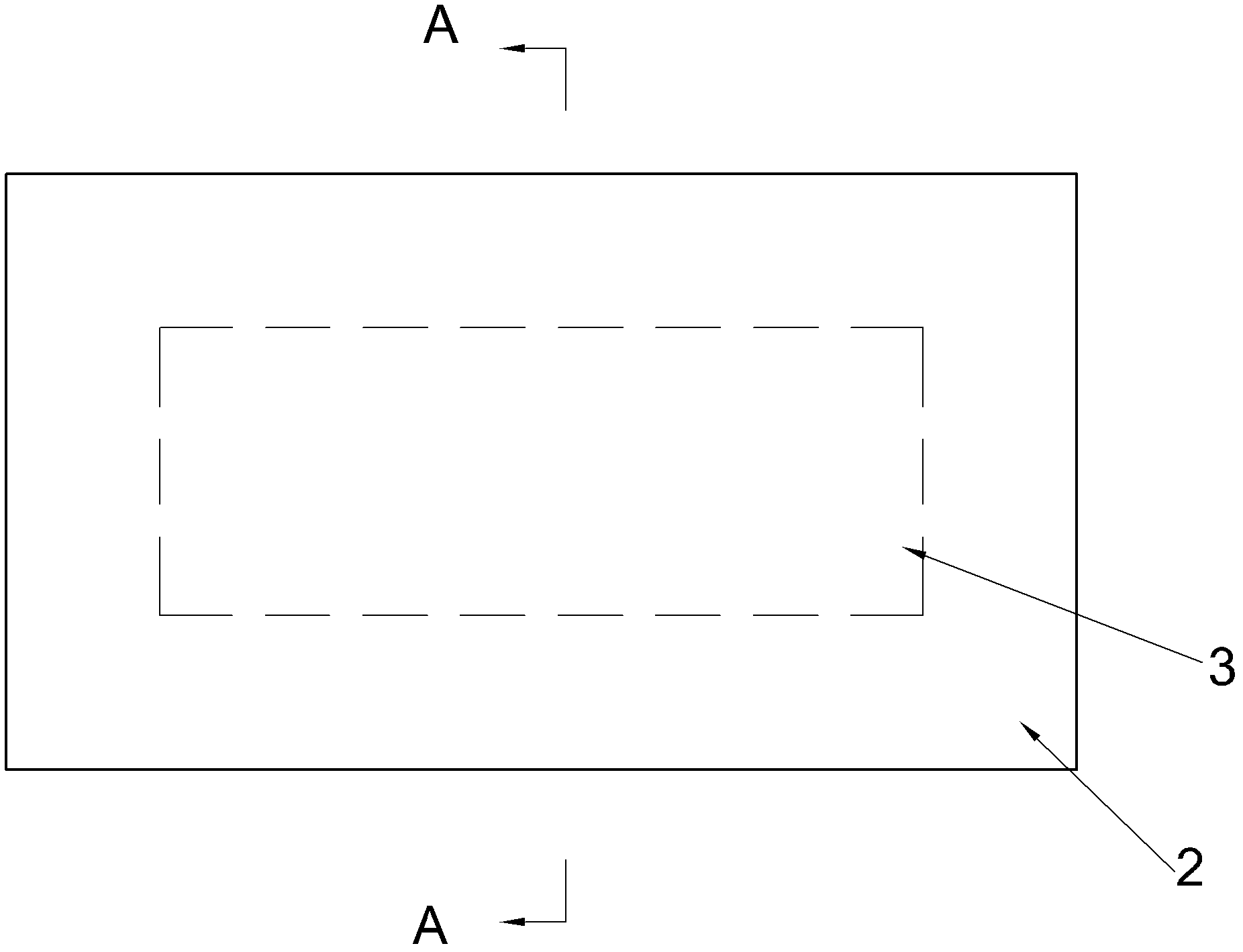

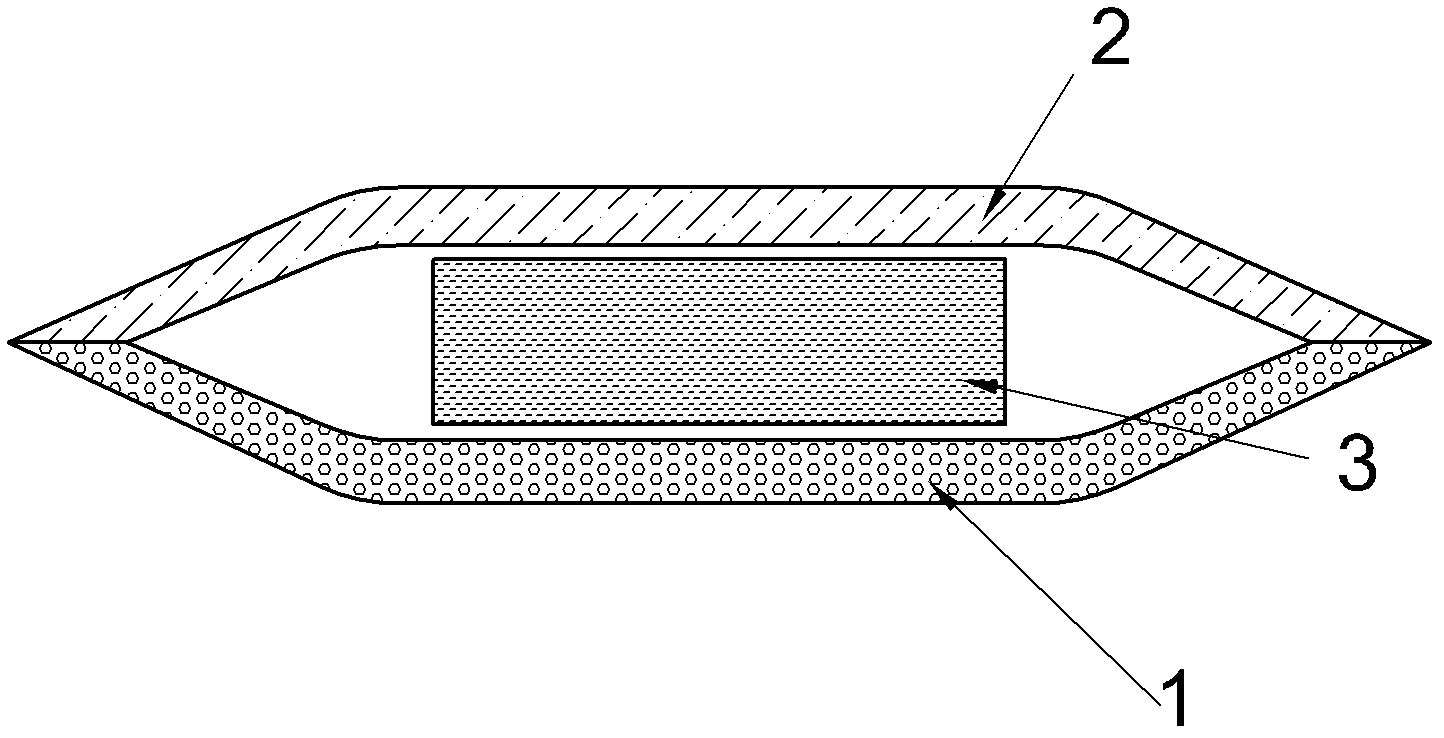

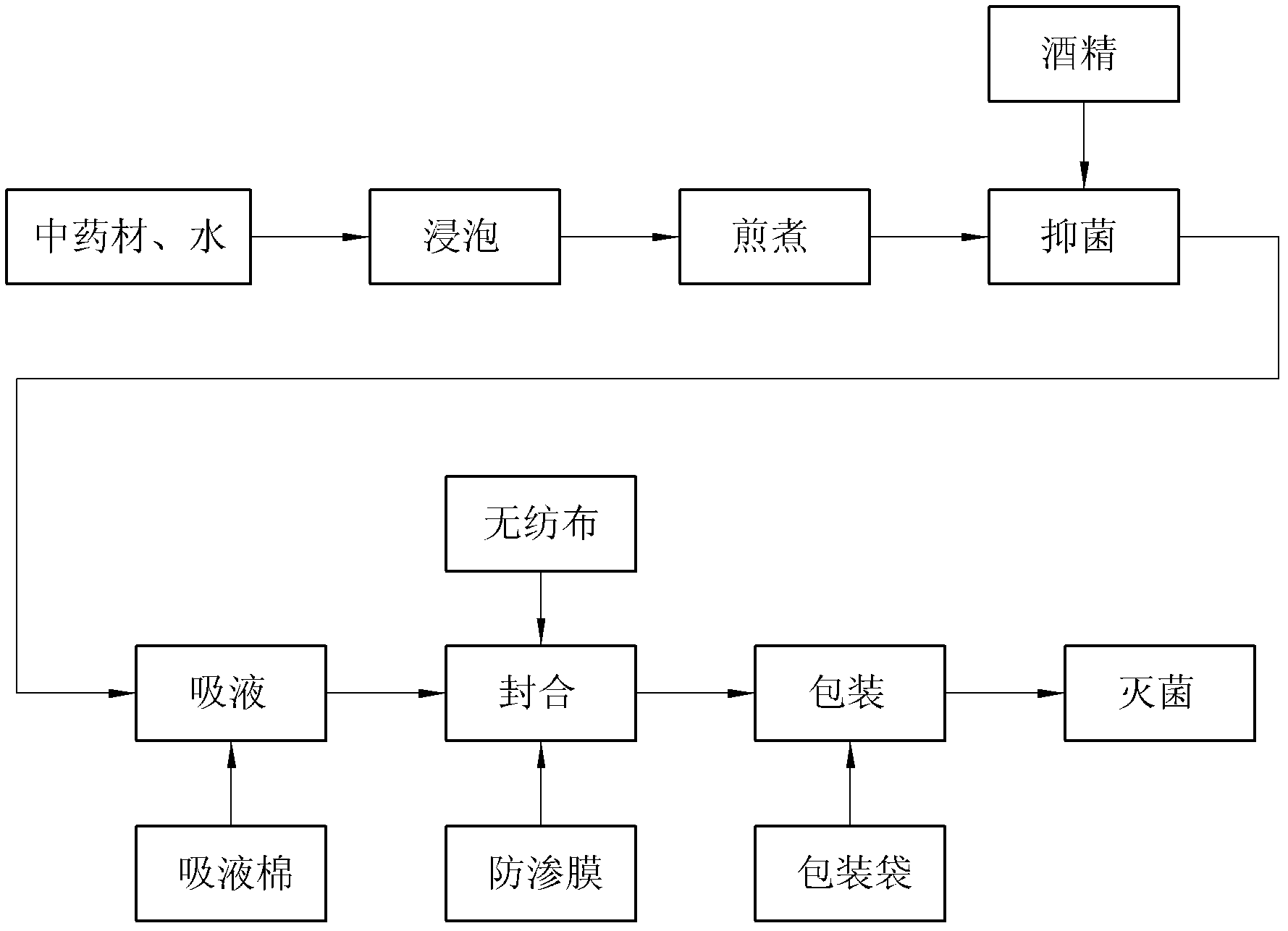

[0030] like figure 1 and figure 2 As shown, the wet compress made by the preparation method of the present invention includes an impervious film 1, a non-woven fabric 2, and a liquid-absorbent cotton 3 wrapped between the impermeable film 1 and the non-woven fabric 2, and the liquid-absorbent cotton 3 There is a traditional Chinese medicine liquid absorbed in it. The anti-seepage film 1 is made of waterproof material, and is used to prevent the liquid medicine from seeping into dirty clothes (when used directly) and inside electrical devices (when used with a heat compress) during the wet compressing process. The non-woven fabric 2 plays the role of penetrating and diffusing the traditional Chinese medicine liquid. The liquid-absorbing cotton 3 is used for absorbing the traditional Chinese medicine liquid, and is a liquid carrier. By heating, the medicinal gas can penetrate the treatment parts of the human body to the greatest extent, so as to treat diseases. The tradition...

Embodiment 2

[0040] The difference between the present embodiment and the first embodiment mainly lies in the sterilization step. In this embodiment, an ethylene oxide sterilization device is used for sterilization treatment, and the sterilization process is divided into a pretreatment stage, a sterilization stage and a post-treatment stage. The pretreatment stage refers to the whole process from loading the object to be sterilized to reaching the sterilization temperature, including 4 to 6 times of vacuuming (negative pressure limit -80kpa), heating up and feeding the drug, and the process time is not less than 30 minutes; The sterilization stage refers to the whole process of timing after reaching the sterilization temperature and pressure. The sterilization temperature is 45°C, the jacket temperature is 52°C, the pressure limit is 90kpa, and the sterilization time is 300 minutes; the post-processing stage refers to after the sterilization is completed. The forced ventilation analysis pr...

Embodiment 3

[0042] The difference between the present embodiment and the first embodiment mainly lies in the sterilization step. In this embodiment, radiation sterilization is adopted, and the dose used is 4 kGy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Liquid absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com